Porsche PDK Transmission – Now REPAIRABLE

This post / blog article talks about the ability to repair a Porsche PDK transmission for certain models / generations.

We have had many stories from our customers like this: “I’ve had my Porsche 911 997.2 with a PDK transmission for a few months now after switching from a manual transmission car. I was considering an extended warranty, mainly due to PDK replacement cost ($25k or more depending on the PDK source). There have been many claims that the PDK is not serviceable but must be replaced as a complete unit in the event of pretty much any failure (i.e. the transmission becomes a disposable component or part of the car). This is pretty frightening as items like solenoids, sensors fail all the time, like any other electro-mechanical device they wear out.”

Fortunately, this worry or concern just isn’t the case anymore, and this transmission is now very repairable. Although this transmission is complex, its not overly complicated and is serviceable in many ways that aren’t readily documented . This work, repair would need to be done by an Independent shop (like BRracing), as the dealer will not undertake this solution, nor will they offer any parts.

For reference, the PDK transmission model used in the 997.x 911 and 991.1 911 Carreras, 987 / 981 Boxsters and Caymans) is a ZF model 7DT45. 911 Turbos use a ZF model 7DT70 which is identical to the ZDT45 except it has a heavy duty clutch, strengthened major components, and slightly different gear ratios, but is still repairable.

There are subtle differences in the six variants (997 2WD, 997 AWD, 991.1 2WD, 991.1 AWD, 987 and 981). ZF 7DT45 and 7DT70 transmission variants were used in the car models from 2009 to 2016.

The PDK did see minor updates for the 991.1/981.1 in 2013 but is still generally the same transmission. These changes include the addition of a gear oil pump and cooler, a gear oil temp sensor, sealed clutch updates, and the option for a true locking differential (including an additional solenoid and pressure sensor to engage/disengage). The 991.2 PDK introduced in 2017 is substantially changed and it’s not clear how much of this info applies. The PDKs in the Panamera and crossovers are completely different units from that discussed here.)

FYI: Porsche Macan’s so called “PDK” is not really a Porsche PDK. It uses Audi’s famous(for failing) DL501 0B5 DSG that can be found in most Audi A4, A5 B8 models and more.

Porsche took Audi’s 0B5 optimized & revised the control module to the best possible configuration thus, highly responsive and much, much more reliable.

This article is fairly technical. It’s meant to provide a complete overview of the PDK on the models noted above, so that should you have an issue, you can review and determine if it falls into the failure issues noted below, and you can know that a solution exists. This is not meant to be the repair guide (Porsche does not produce any repair guide or documentation, consistent with their approach that the transmission should be replaced, not repaired. We have had to develop all our own tools (and there are very specific tools needed to do the various repair options)), as well as our own technical repair manual (our manual is now over 100 pages, and inches thick). This has come from our investigation, and research for well over a year.

911 / Boxster / Cayman PDK Flaws

Just like many other double clutch transmissions out there, Porsche’s PDK has several key elements that can fail, and that now, are all repairable:

– distance sensor (the most common failure)

– other sensors (speed, pressure)

– valve body, solenoids

Let’s dive into the fault codes that could be present if your PDK starts to fail (this is not a 100% fully inclusive list, ,but the list we have been able to document):

Fault Codes Present Related to the Distance Sensor:

You might get faults like the following but not limited to:

P1731: Shift rod 1 displacement sensor

P1732: Shift rod 2 displacement sensor

P1733: Shift rod 3 displacement sensor

P1734: Shift rod 4 displacement sensor

P17XX: 5V … displacement sensor

If you get any of these faults, it is very likely that your displacement sensor has failed or is failing. If you can’t be certain, always refer to the actual data values (viewable via the PIWIS unit / system), they are helpful.

Other Fault Codes related to the PDK:

Overview of fault memory entries for pressure sensor

– P0841 and P0846: Pressure sensor fault (measured value implausible)

– P17B1 and P17B2: clutch fault(activation pressure implausible)

– P17B3 and P17B4: clutch value pressure stays too high mechanically during overlap switching and quick filling

– P17BB to P1717BE: clutch fault (clutch can not be opened)

Overview of fault memory entries for temperature sensor

– P0711: transmission temperature sensor implausible

– P172D: transmission temperature sensor gradient fault

– P17F0 to P17F2: transmission overtemperature fault

– P1706 is the clutch pressure sensor. Good news is that this part is available from Porsche or ZF (has been superceeded to a newer version). The resistance can be measured at the TCU prior to taking the transmission out. Here are the pressure sensor pinouts:

PDK Connector (A connector, closest to engine):

- Pressure sensor 1: A11

- Pressure sensor 2: A12

- 5 Volt supply: A13

TCU Connector:

- Pressure sensor 1: B30

- Pressure sensor 2: B31

- 5 Volt supply: B20

Overview of fault memory entries for software faults

– P0602: control unit not programmed

– P0603: EEPROM emulation checksum incorrect

– P0604:RAM test failed

– P0605: flash checksum incorrect

– P0614: data status does not match engine

– P0702: watchdog (monitoring unit)

– P1749: variant coding invalid

– P1870: data record for shift rod synchronization failed

– P1871: data record for clutch synchronization failed

– P1872: data record for HYT1 synchronization invalid (hydraulic teach in)

– P1897: software monitoring: calculation of speed control intervention by engine implausible

– P174B: invalid allocation of control unit and transmission hardware (cross-installation)

– P174C: BIN file does not match software version

– P174E: EEPROM content at system start incorrect / implausible

– P186F: data record for electric synchronization data invalid

– P189A to P189D: software monitoring

– P18A0 to P18B5: software monitoring

Overview of fault memory entries for gear selection

– P17D0 to 17D9: hydraulic gear selection fault

– P1779, P177A to P177F: synchronization fault (gear can not be disengaged)

Overview of known faults for the Mechatronics / Valve Body Control Unit (TCU)

– P17D400: Clutch valve in gear train half 1, mechanical fault

– P17D500: Clutch valve in gear train half 2, mechanical fault

Overview of other fault memory entries for temperature related issues:

17F0 – Transmission overtemperature

17F1 – Transmission overtemperature

Faults for Speed Sensor

P173D – Speed sensor clutch 1, short circuit to B+ (we have not found that this means the sensor is dead)

These are the standard over temp faults and aren’t unusual during heavy duty track use, it simply means the clutch fluid in the sump has gone above the limit set by Porsche. One fix to this is the LN engineering heavy duty PDK clutch fluid/water heat exchanger. There’s also an aftermarket pump/cooler that can be added to the PDK gear oil section (we have done this and seen success on Porsche 987 Caymans), neither the 997 or 987 came with one. Porsche added a gear oil cooler in 2013 to the 991/981 as standard equipment

So, let’s look at the repairs we have performed, all with complete success, and then we can dive deeper into the details of the transmission. We will try to provide you slightly different views of the critical elements and steps in the repair of each.

Porsche 997.x Carrera S PDK Repair

This is exactly the nightmare…customers car started shifting harsh, then not shifting at all. Talked to many shops, dealers, all said couldn’t be repaired, needed a new transmission. Car was parked till he talked to us.

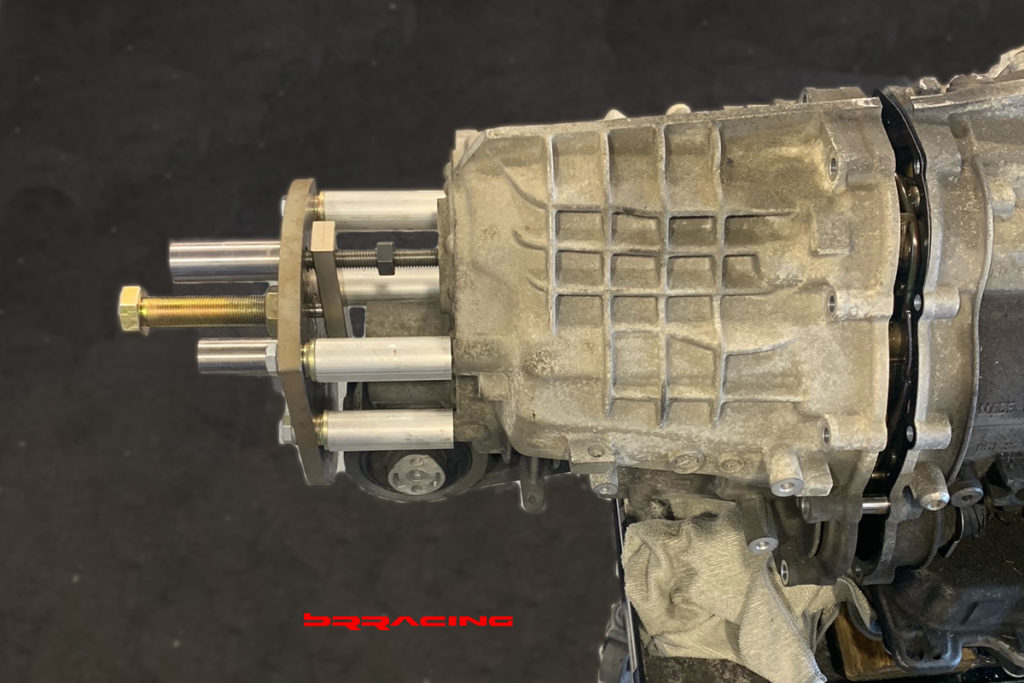

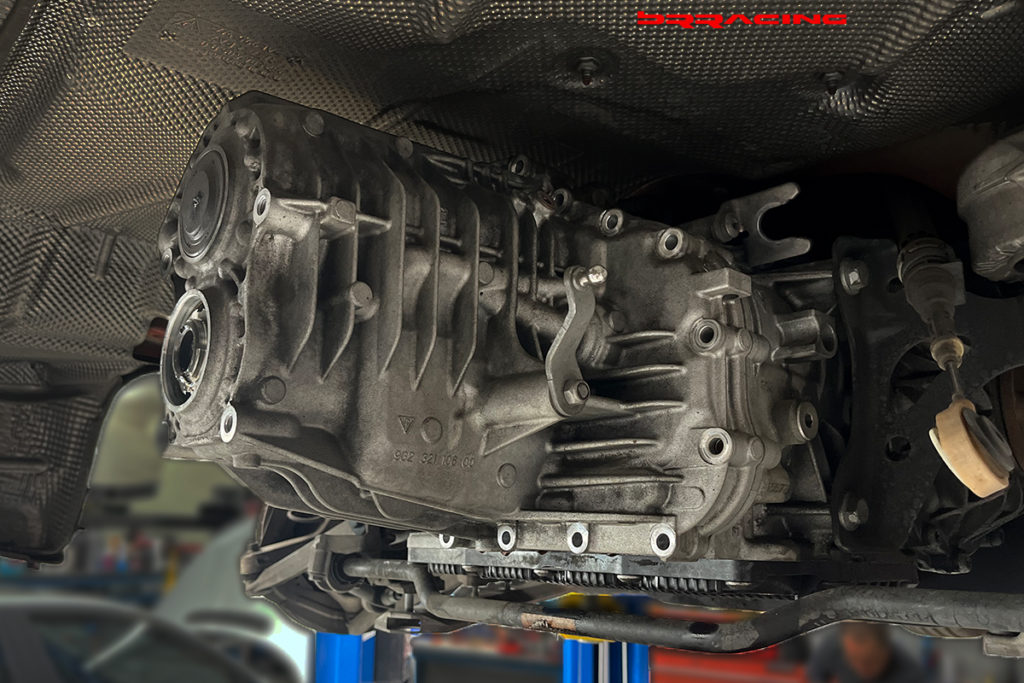

But now, there is not just a glimmer of hope, there is a solution. To get this started, on a 997 911, you have to pull the complete transmission out of the car, then start the process of opening the case. Custom tools need to be developed to perform the breaking of the case, and the case has to be pulled off at a perfect, straight angle. There are bearings and pins inside, and these parts do not exist, so great care needs to be exercised.

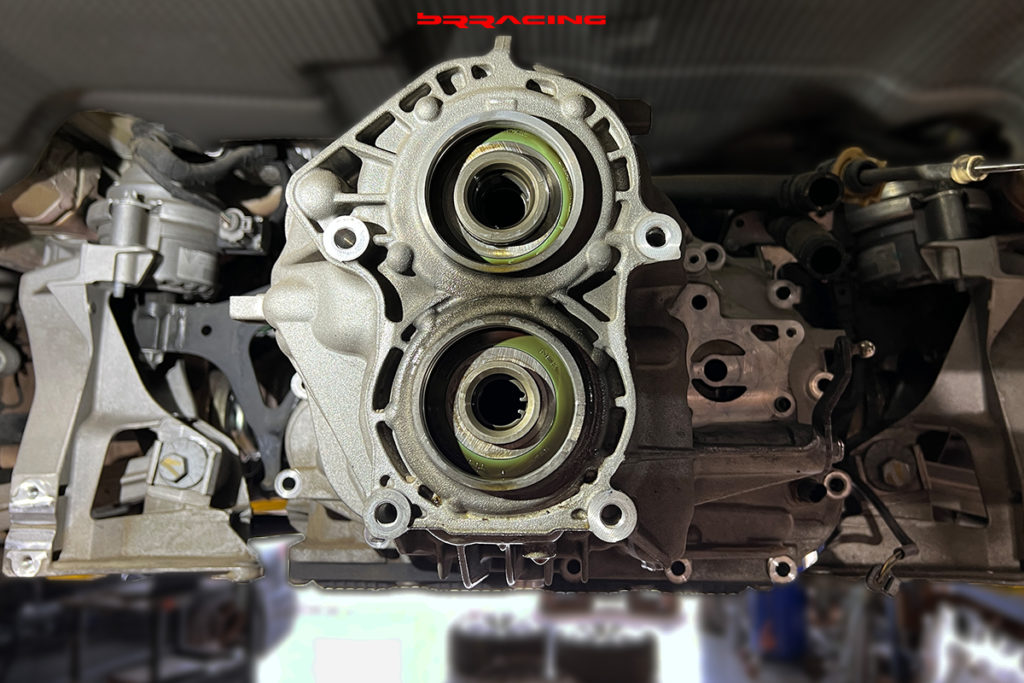

There are two rear caps, those need to be removed (along w all the securing bolts), before the tool can be inserted to start the removal of the rear casing.

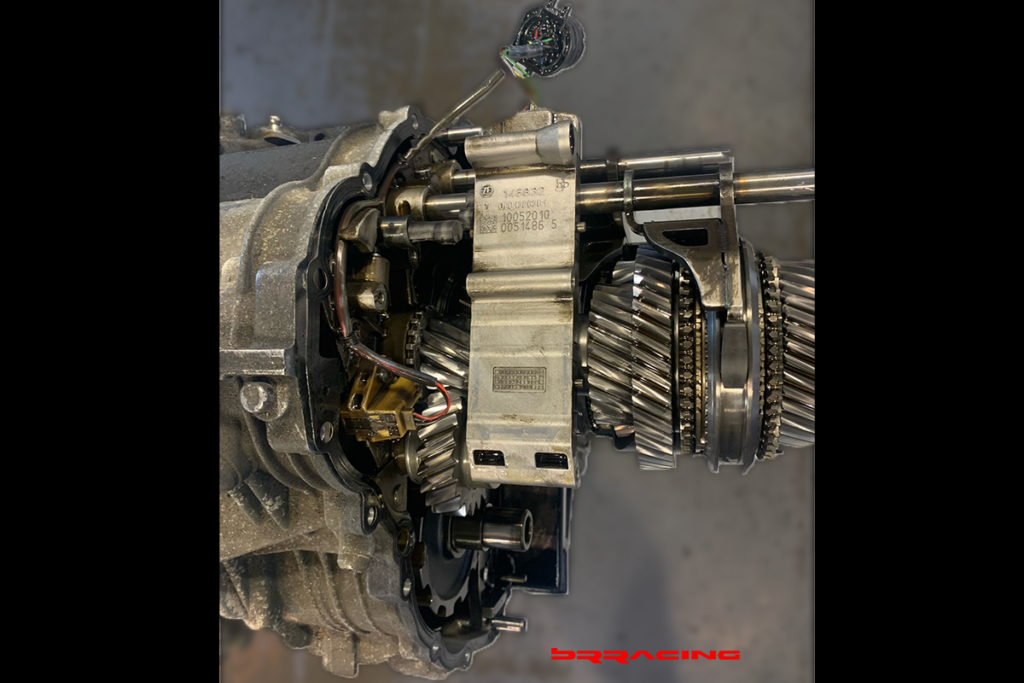

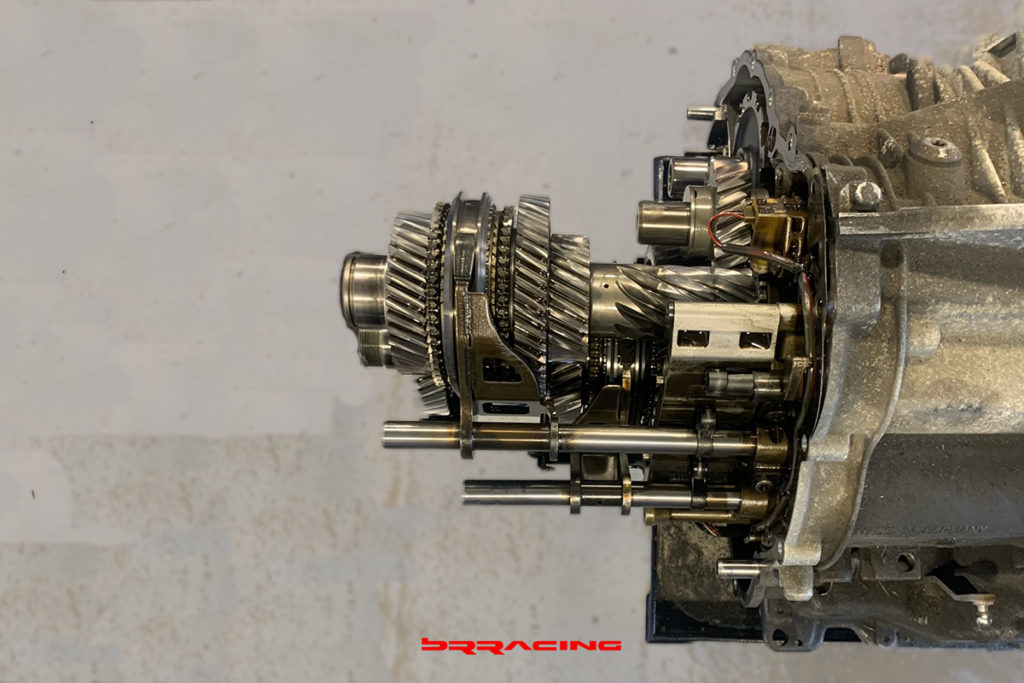

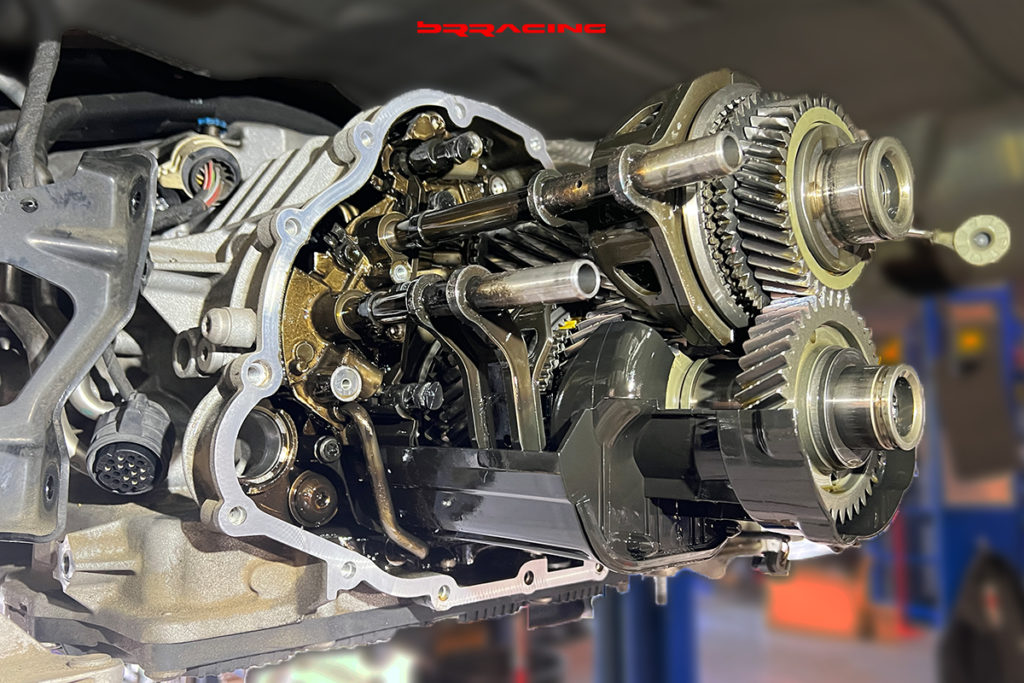

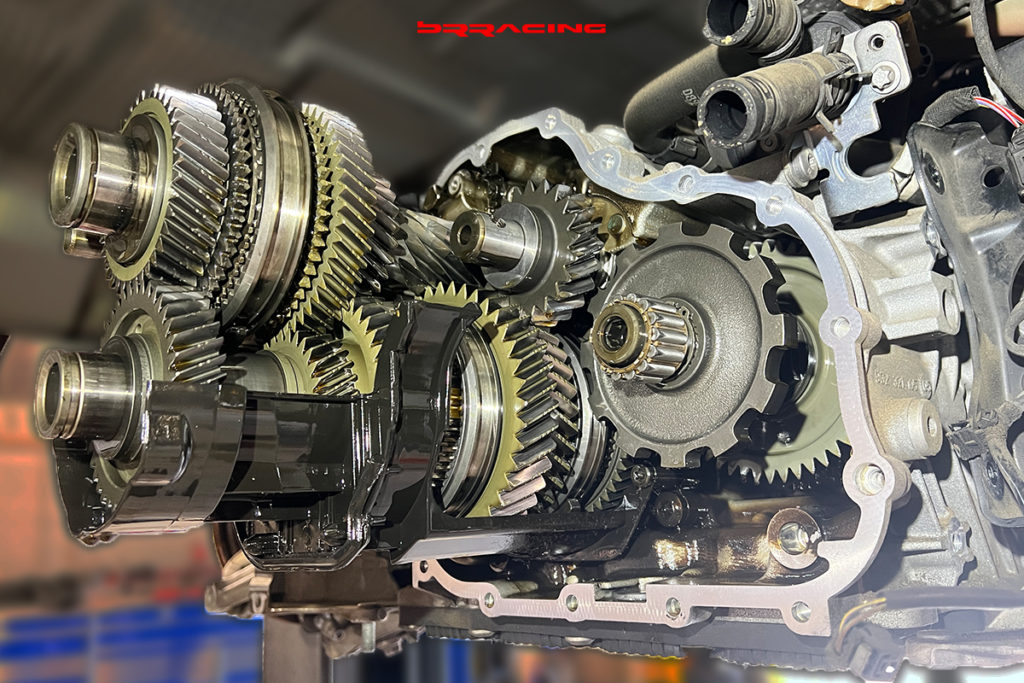

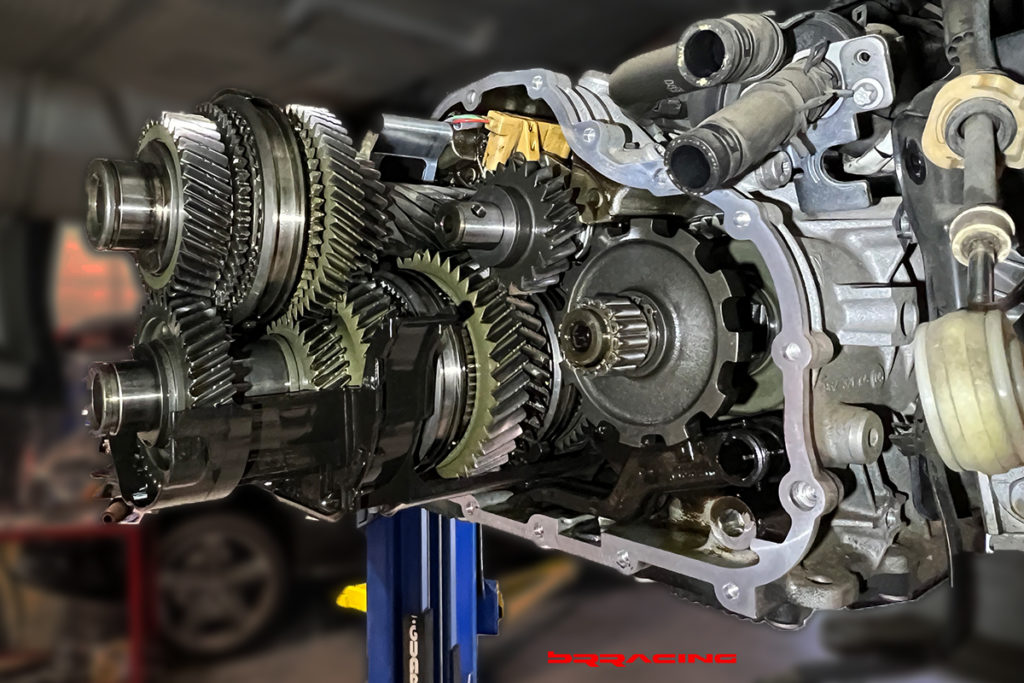

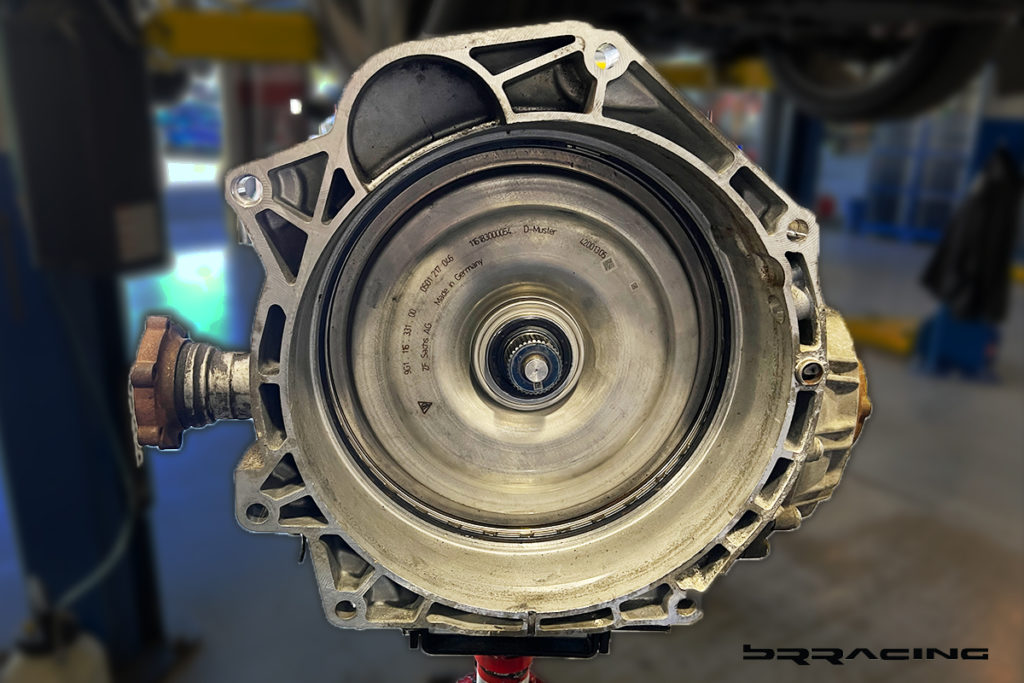

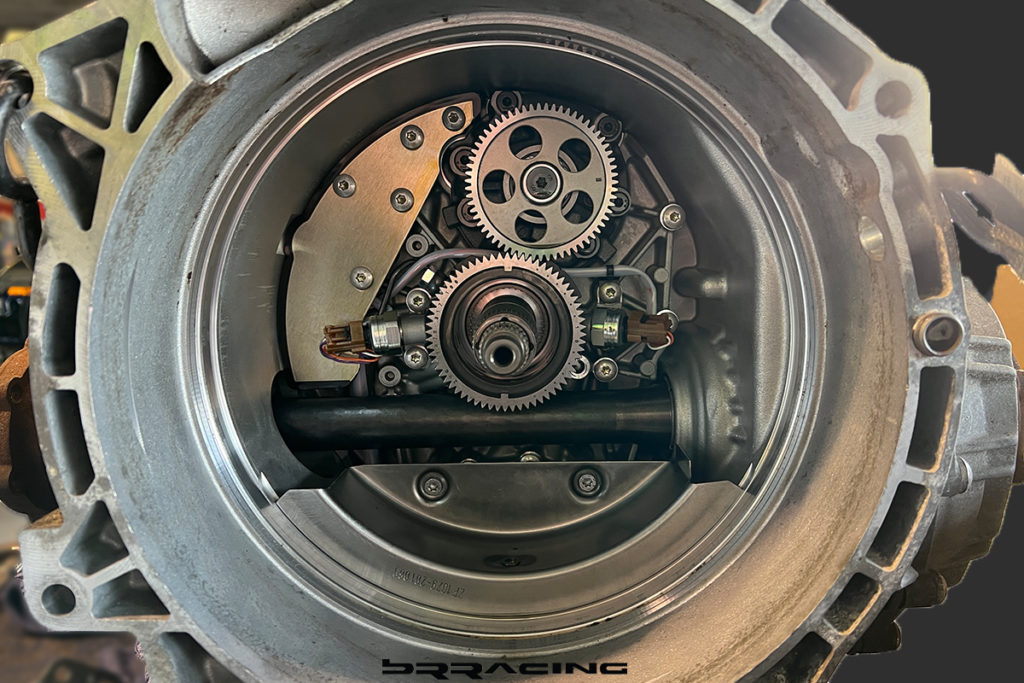

This is the view once the rear case has now been removed.

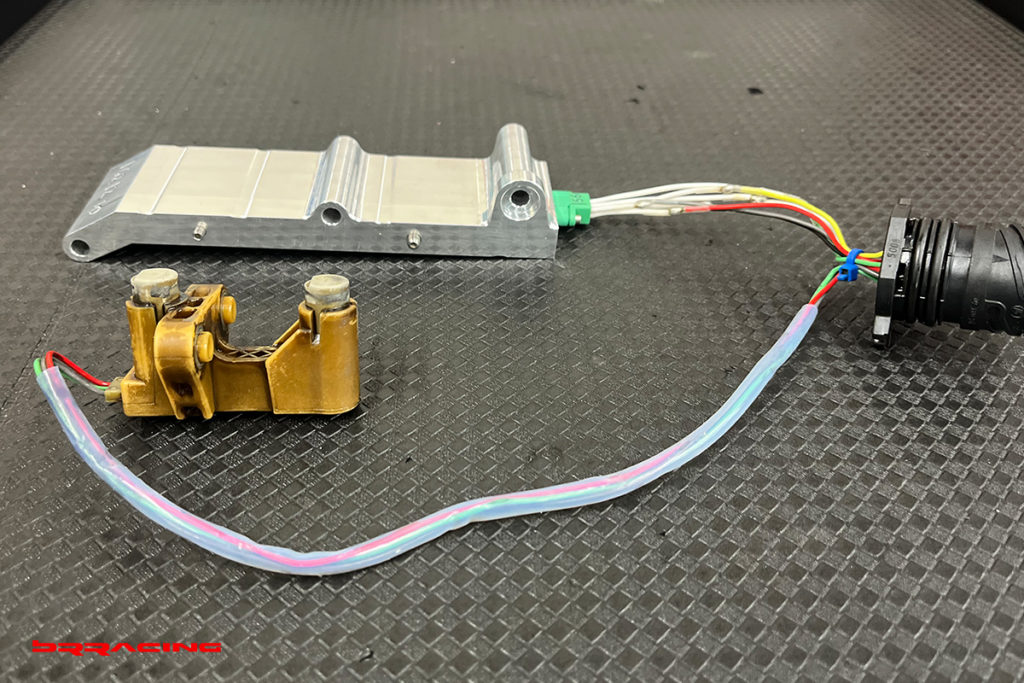

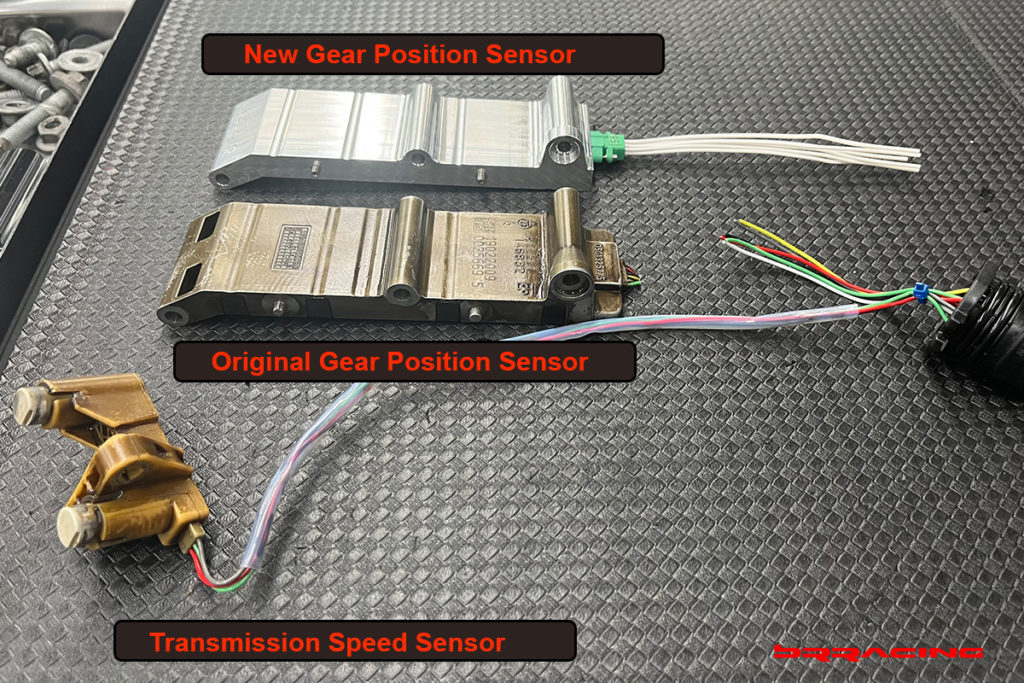

Below is the original OEM / ZF distance sensor removed from its location. This is a magnetic sensor, and it can read the location of each gear (which have magnets on them).

In the picture below, the distance sensor has been removed, but the speed sensor is still in place (at the top).

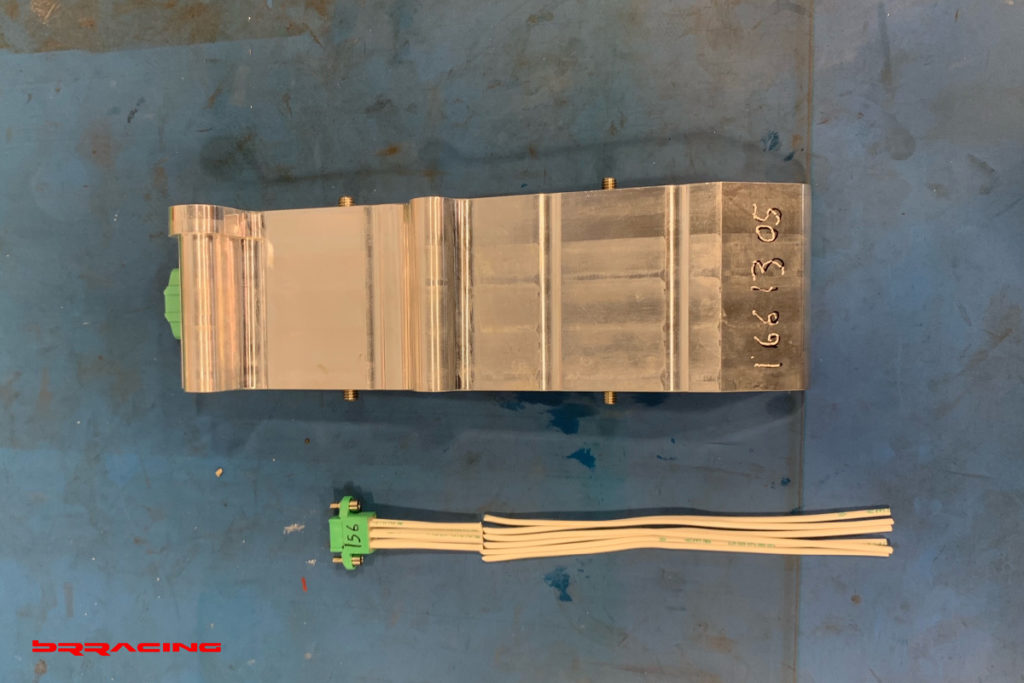

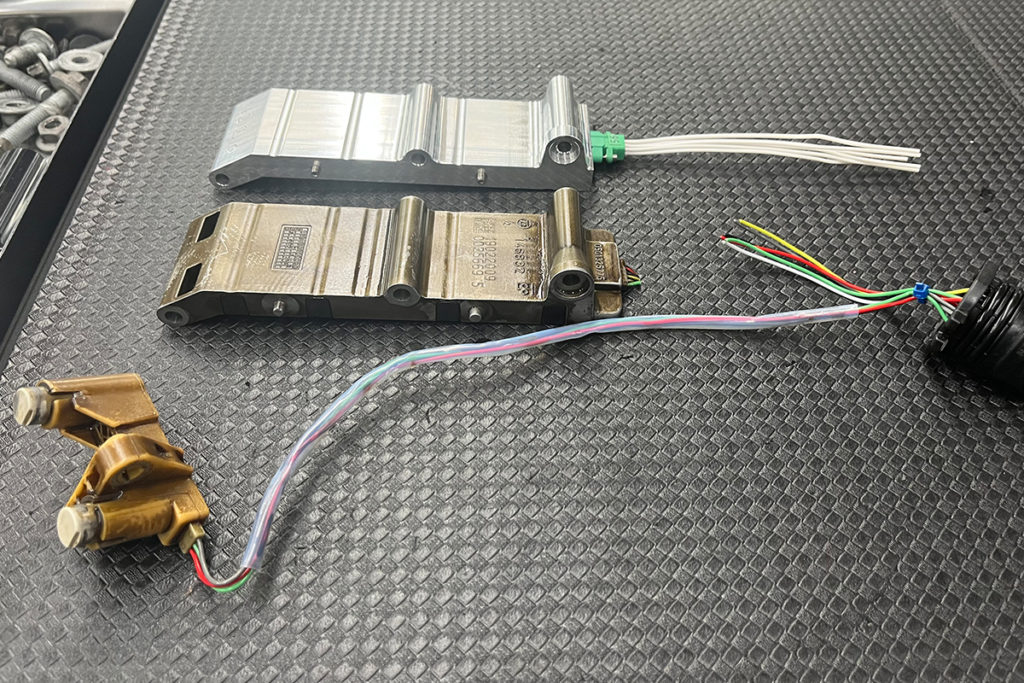

Below is the new distance sensor. The replacement distance sensor comes w a new wiring harness, but all the wires are not color coded, so another step is, this wiring harness needs to be integrated and matched to the existing transmission wiring harness.

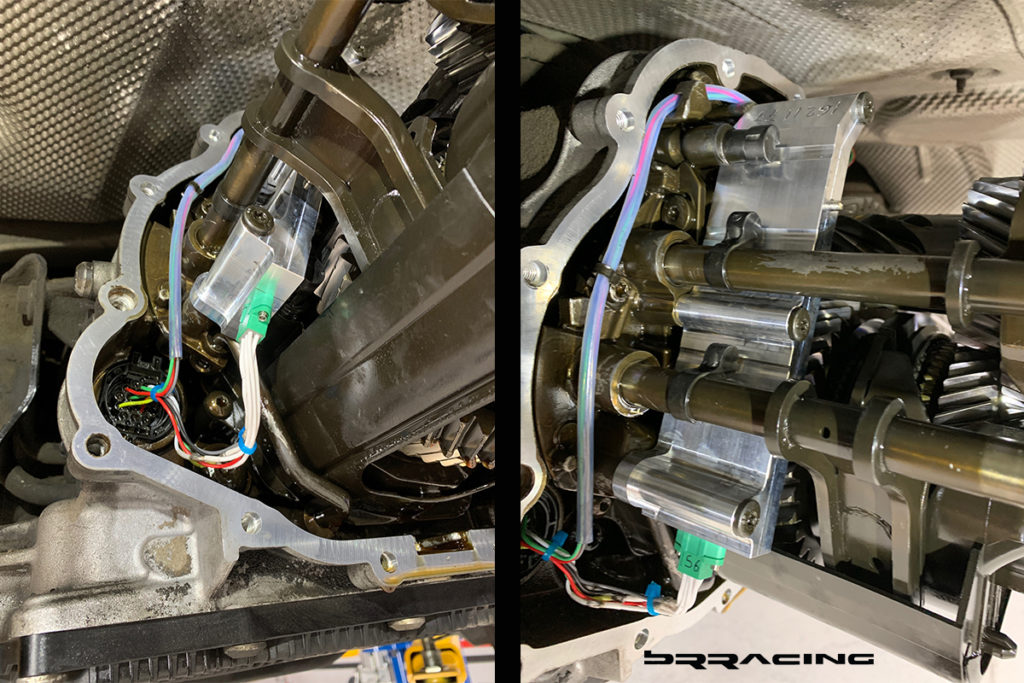

Below, the new distance sensor is installed, wiring harness in place.

Below, another view of the gear portion of the transmission with the new distance sensor installed.

Once the new sensor is installed and integrated, the transmission is re-assembled. Once complete, and back in the car, the fluid process needs to be completed. Finally, the transmission has to be re-calibrated. Sometimes, using the PIWIS system, that goes easy, sometimes it throws you for a loop, and you just need to try again. For this customer, it was a HUGE success…we got the car working properly, correctly, and the joy of his Porsche has returned.

Porsche 987 Boxster S PDK Repair

Same story here, but different car, different version of the PDK. Customer did not have high mileage on the car (about 80k miles), and transmission started to act up, not performing shifts when requested. This was a slow progression, and those who think that it would be better w a fluid / filter change…that would do nothing, and might even make it worse. A PDK repair was what the codes showed was needed.

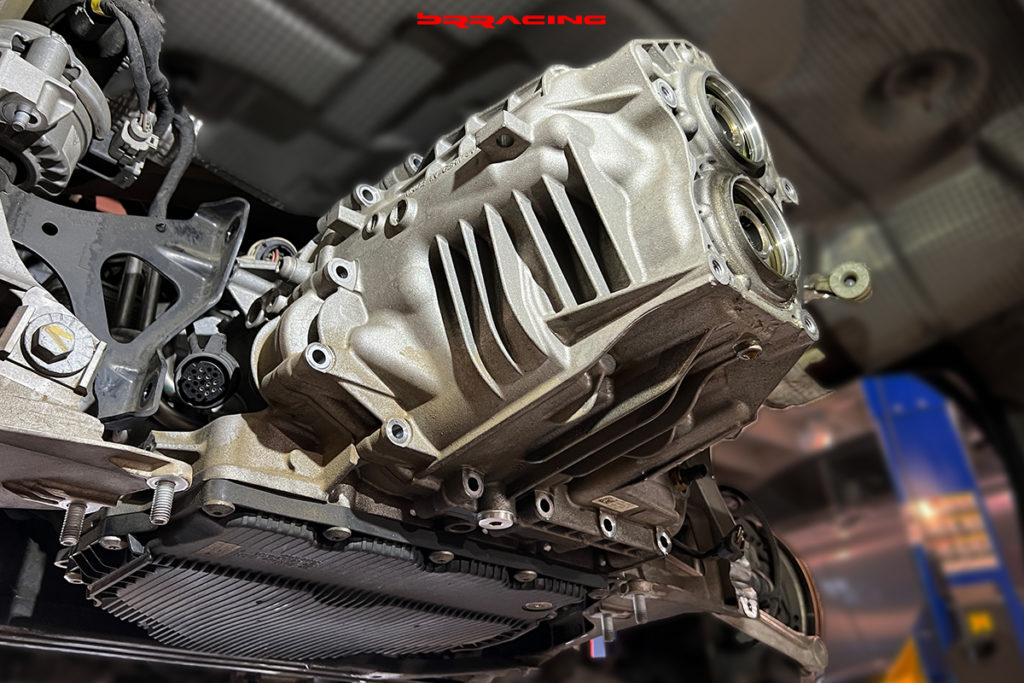

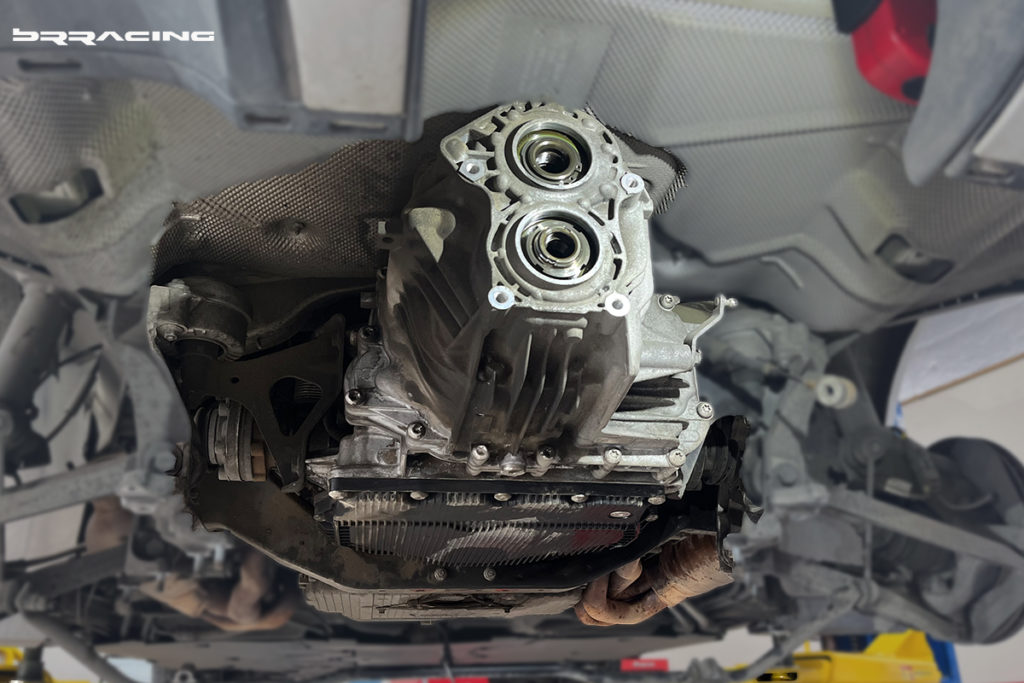

Below is the view of the underside before we start the removal of all the other elements needed to get out of the way to perform the surgery on the PDK.

For the Boxster and Caymans, the transmission can be left in the car. In the image below, you can see one of the rear end “caps” still in place, and one removed. These are parts that you can get, and should be replaced as part of the process.

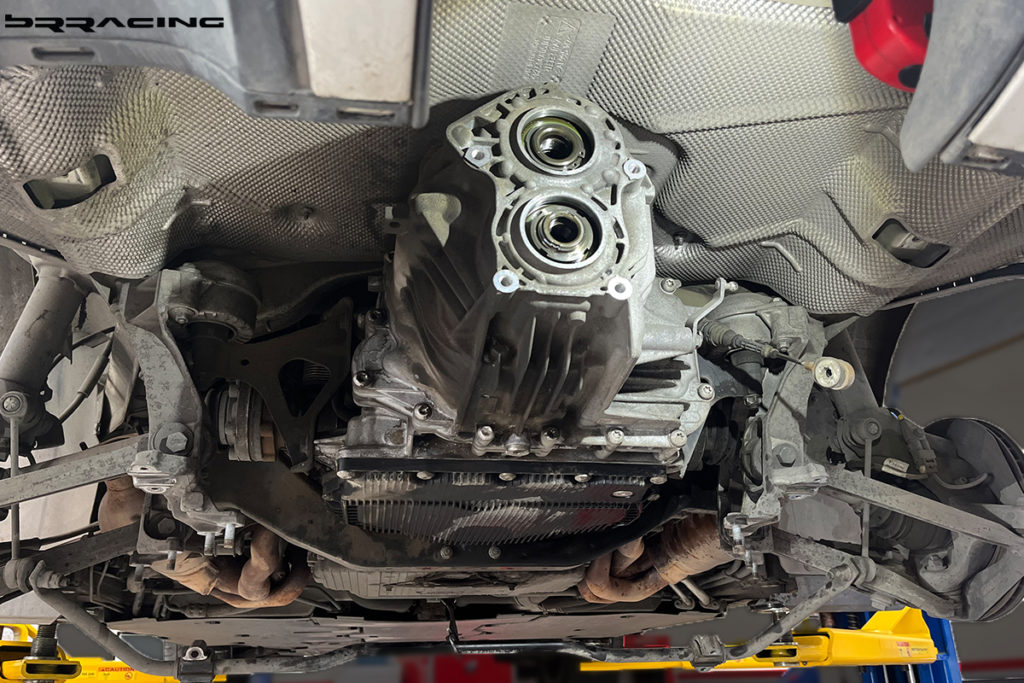

Below, both end caps are now removed, and the delicate process of removing the case starts.

The new distance sensor and the speed sensor, now fully assembled and integrated, ready for installation back into the transmission.

Since Porsche provides no documentation on this, you have to develop your own wiring diagram to do the wiring harness integration. There has even been discussion on how to integrate…do you crimp the wires, or do you solder the wires. Remember that these will be submerged in transmission fluid.

Again, same process. Once the new distance sensor is assembled, and installed, then the transmission can be assembled. Fluid fill process performed, and then the transmission re-calibration performed.

Porsche 981 Boxster S PDK Repair

This was another nightmare. Customer had car and it was due for service. Took to the dealer, dealer did the service, and then called the customer and said the PDK is now broken, and the only option, is to replace the PDK transmission. The dealer wasn’t even clear on what happened, what codes were present. The guidance from the dealer was the only option was to get a new transmission…. Customer pulled car from dealer, had it towed to us, to perform the diagnostic and repair. Ran diagnostics, tested operation, and sure enough, had the codes that indicate a failed distance sensor.

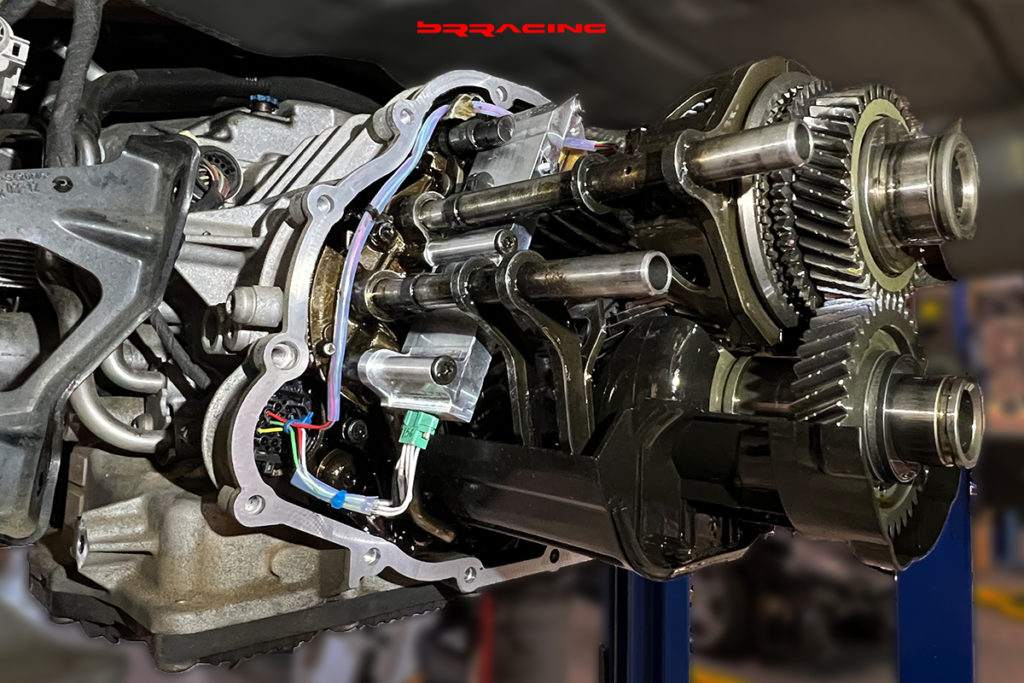

Transmission still in car, all other elements removed, ready to perform the case split and removal.

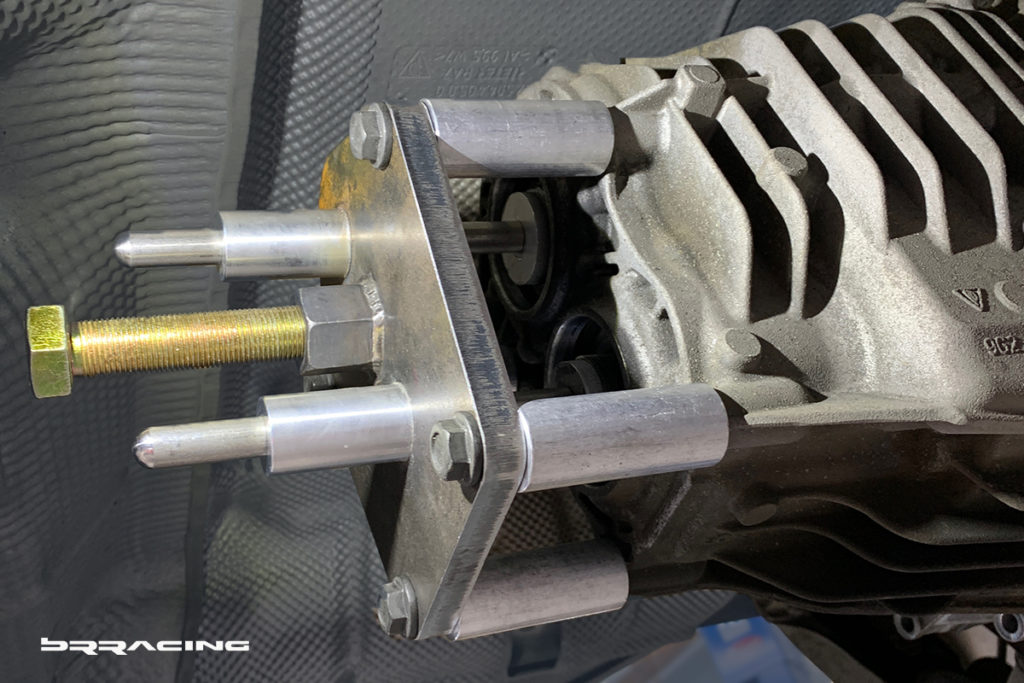

View of the rear, in preparation for the case removal. But, a close look also shows that the internal shafts are threaded….found that when you press off and press on the case, the internal shafts can move fore and aft. Another tool set needed to be developed to allow us to shift the internal shafts into the proper location. Easier said than done…one of the threaded shafts has a thread and pitch of M24 x 1.5. This is NOT a normal thread pitch for that large of a diameter, so that too needed to be fabricated.

Case off, internals exposed, distance sensor now removed (along w wiring harness and speed sensor).

View from other side of the box, with sensors and harness removed.

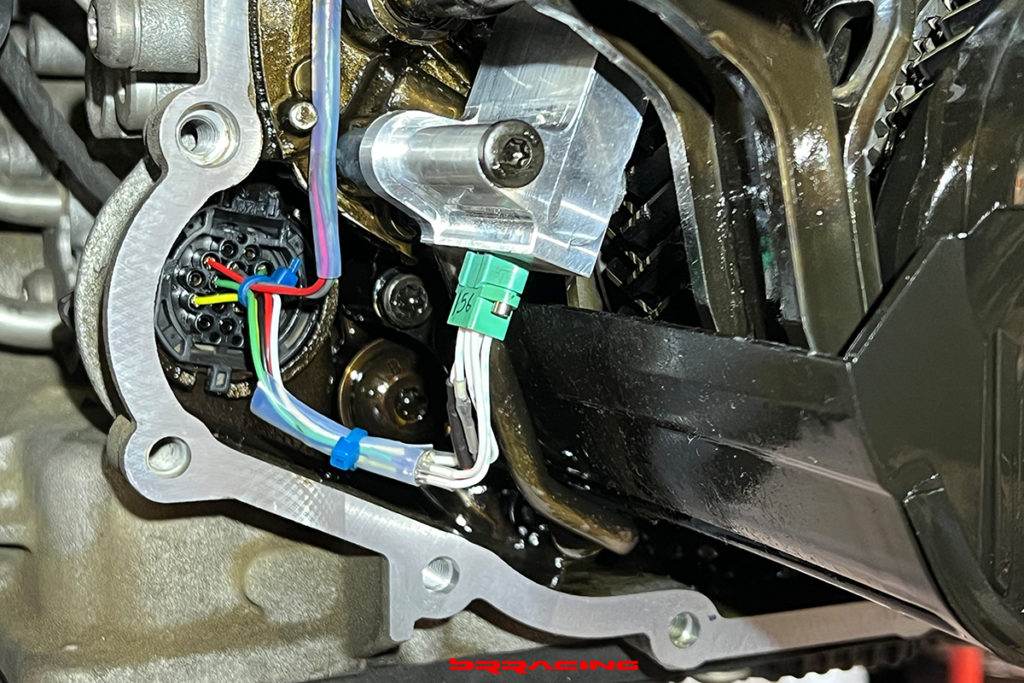

New distance sensor installed, wiring harness integrated, speed sensor installed.

Up close view of the integration of the new distance sensor, it’s connector, and the original wiring harness.

Up close view of the top of the box, where the speed sensor is located and now re-installed.

Porsche 987 Boxster S PDK Repair

No tragic story here…just a transmission that started to behave poorly. PDK, w about 60k miles. Ran diagnostics, had the known codes / errors for the distance position sensor failure.

Specialty tool set that needs to be developed (not available from anywhere to purchase). The tool kit is different for the different PDK transmissions.

New distance sensor and wiring harness installed.

Transmission assembled, fluid filled and set w PIWIS, transmission calibration performed, and now working just like new. In all of the PDKs we have now repaired, we have not found any other issues w the transmission or gears. Transmissions are solid, sensors…not so.

Valve Body / Solenoid – Technical Review / Issues

A PDK control unit fault code relating to accessing a specific gear (or inability to shift to a specific gear) is very likely a valve body solenoid issue. In addition, there are also electrical sensors within the transmission that monitor responses to solenoid action and report status to the transmission control unit. Sensor failures can also cause faults and are discussed later in this post.

New replacement valve bodies (complete units) can be sourced directly from Porsche. This is a universal part for transmissions used on 911s, Boxsters, and Caymans. The 997.2 part number is 9G1.317.897.00 (for 2009-2012 Carrera, Turbo, and GT3).

There are also other identical looking valve bodies available from Porsche under part numbers that apply to different years: 9G1.317.897.05 (2012-2015 911), 9G1.317.897.010 (year unknown), and 9G1.317.897.35 (2012-2015 911 and 2014-2015 turbo/GT3). Its not clear what the difference is between these units so its probably best to eyeball the existing valve body prior to ordering a new part just to be safe (the PN is on the bottom and can be seen by removing the pan). It looks like the part numbers rolled for later 911s and that 9G1.317.897.00 applies to all 997.2 PDK models, but this is not absolutely certain. Note that 991 valve bodies include an additional check valve that is required for the autostart feature so it’s important to use the correct part number.

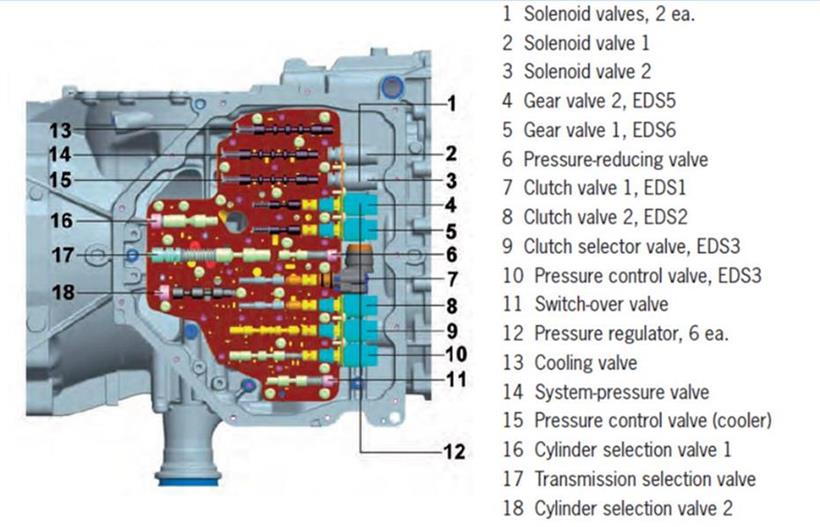

The information below regards the function of the various solenoids in the valve body. This info was compiled from reviewing solenoid function with various ZF transmissions with publicly available documentation and refers to the designations in the drawings. Some of the info below is supposition based on how ZF has implemented transmission control in the past, and it cannot be guaranteed as 100% accurate (prefaced with appears to).

The patterns noted below should be helpful in troubleshooting malfunctions that result in missing gears or shifting problems.

Solenoid types there are two different solenoid types used in the valve body, EDS type and MV type, all are controlled by the TCU

* EDS this solenoid type regulates hydraulic fluid pressure over the range of 0 bar to 4.7 bar. Pressure regulation is either proportionate to the supplied current, or inversely proportionate depending upon the solenoid type

* MV these solenoids are simply ON/OFF switches that either provide or remove hydraulic pressure within the system.

EDS4 This EDS solenoid regulates overall system hydraulic pressure. Pressure is built up by the clutch fluid pump, this solenoid regulates circuit pressure by bleeding some fluid back to the pan thus bypassing the valve bodys hydraulic system.

EDS1 and EDS2 These solenoids regulate hydraulic pressure to the two clutches. The clutch system is adaptive in that hydraulic pressure is varied to account for clutch wear over time. This is done by adjusting pressure within the clutch if the TCU senses slippage or otherwise slow engagement (monitored via the driveshaft speed sensor discussed later). There are two solenoids as each clutch has its own unique adaptive capability. EDS1 controls fluid pressure to clutch 1 which engages/disengages gears 1, 3, 5, 7, and R. EDS2 controls fluid pressure to clutch 2 which engages/disengages gears 2, 4, and 6

Hydraulic fluid pressure is regulated between the two clutches so when one is engaged the other is disengaged. During gear shifts, there is overlap between the two. Both clutches can be disengaged at the same time when the vehicle is stopped or in neutral.

EDS3 This solenoid controls an auxiliary fluid path for clutch cooling purposes.

EDS5 and EDS6 These solenoids regulate hydraulic pressure applied to the shift fork control rods within the gearbox. There are two separate shift fork hydraulic circuits, one circuit to put the shift control rods in the retracted position, and another circuit to put them in the extended position. EDS6 appears to control fluid pressure to drive the shift rods to the retracted position, which applies to gears 1, 2, 4, and 7. EDS5 appears to control fluid pressure to drive them to the extended position, which applies to gears 3, 5, 6, and R. Failures that result in missing gear patterns like these can potentially be traced to these solenoids.

MV1 and MV2 (items 2 and 3) are binary control solenoids (on/off) that control shift fork actuation. These solenoids work in tandem with EDS5 and EDS6 in selecting gear engagement. How their actuation maps to specific shift settings is unclear, but there is undoubtedly a truth table using MV1, MV2, EDS5, and EDS6 with combinations specific to each gear.

There is a calibration procedure that is almost certainly required after replacing the valve body or a solenoid that will need a PIWIS and can be done by a good independent shop. There’s nothing special about the solenoids in the PDK, the same parts are used on many ZF transmissions including those on BMWs, Audis, and Jaguars.

Orange (EDS type): 0501 214 958 (ZF OEM PN)

White (EDS type): 0501 214 959 (ZF OEM PN)

Black (MV type): 0501 319 037 (ZF OEM PN)

Short orange (EDS type)

Sensors – Technical Review / Issues

The next three sections of the post detail the four sensor types in the transmission that provide data to the transmission control unit. Issues with any of these sensors will cause errors and may make the car undriveable as the control unit will think something is not functioning correctly.

Sensor types:

* Temperature sensor – one sensor, provides the control unit the clutch fluid temperatures

* Distance sensor / Position Sensor (gearshift position) – four sensors in a single package, provides the control unit data on the gear position during and after shifts

* Speed sensor – two sensors in one package connected to the distance sensor, provides the control unit data on the input driveshaft speed

* Pressure sensor – two discreet sensors, provides the control unit with clutch fluid pressure into each clutch assembly

Failed Temperature Sensor

Another item that fails often is the clutch fluid temperature sensor. This is noted in numerous Porsche forum posts and a Porsche service bulletin. In this failure the ECU throws a fault claiming the PDK needs immediate service (gearbox emergency operation message) even though there is actually nothing wrong with the transmission. It also stores fault codes P0711 and P172D in the PDK control unit. In the 997.2 PDK this sensor is located above the valve body and accessible without removing the transmission.

Porsche provides a temperature sensor repair kit (PN 997.612.930.01)

This was a known defective part that was often replaced under warranty. The service bulletin claims you need a special crimp tool to install the new sensor and that only one crimp tool will be provided to each dealership (apparently it is a very special tool). (FYI: you can get the magical crimp tool from Digikey, about half the price of what Porsche lists) However, there is absolutely no reason the new sensor wires can’t be soldered rather than crimped (using high temp solder to be safe), sealed, and covered with chemical-resistant shrink tubing. The service bulletin goes on to make this completely ridiculous statement:

Per Porsche:

– all strands of the line must be covered (crimped)

– if more than two strands are sticking out of the insulated cable connection sleeve following crimping, the PDK TRANSMISSION MUST BE REPLACED!

This is exactly the kind of nonsense that has misled many Porsche owners into thinking the PDK is disposable and they need to drop $25k or more for the failure of a single part. There’s no reason the crimp cant be repaired or even splice in a section of new wire if the connection is somehow fouled up. Yet some dealership will solemnly state the transmission is toast because that is what the bulletin says.

As with the valve body, the temperature sensor health can be assessed via a resistance measurement at either the transmission “A” connector (difficult to access in the vehicle) or the TCU harness connector. Resistance varies with temperature so it’s best to measure when the clutch fluid is at a known temperature (i.e. at room temp from being fully cooled off after use).

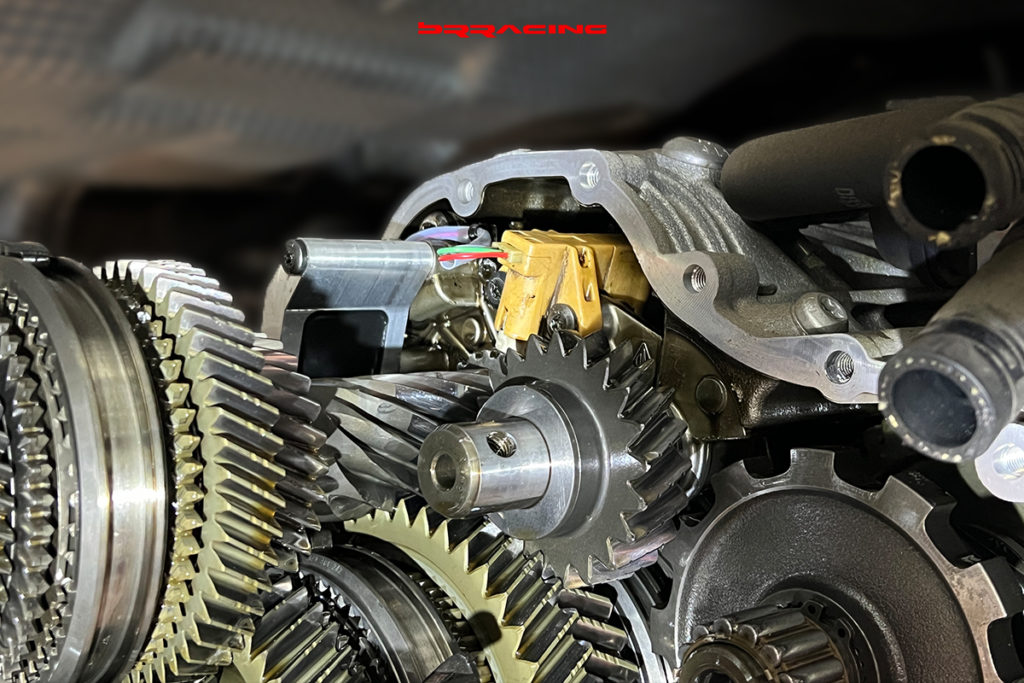

Gear shift rod Position Sensor (distance sensor) and Speed Sensor failures

The gear position (distance) sensor is an electric sensor that measures the position of the control rods that engage gears within the gearbox. The purpose of this sensor is to verify things moved to the correct location when hydraulically commanded via the solenoids. These sensors are also used during PDK calibration as the transmission control unit correlates solenoid movement with gear movement. A faulty sensor will cause the transmission control unit to think the transmission is not shifting correctly. So far, in all of our customer base, this is the most common failure within the PDK.

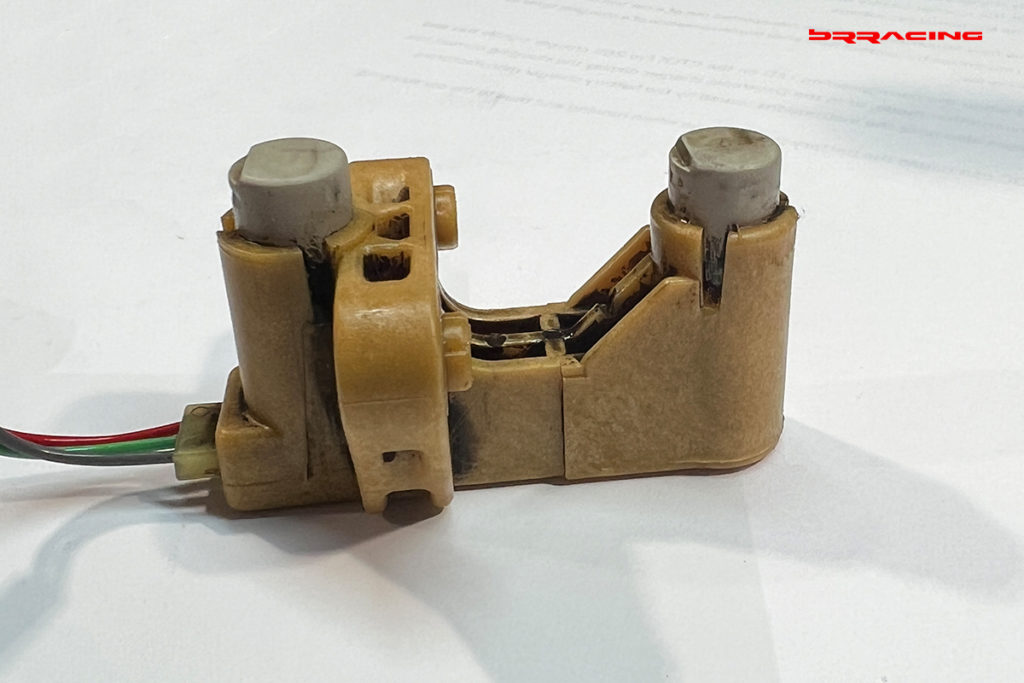

The yellowish device that is part of the distance sensor wiring harness consists of two separate Speed Sensors. These measure the RPM of the two different input driveshafts (two clutches = two driveshafts). This mounts above and behind the gear selection sensor inside the gearbox section and provides data to the transmission control unit. There is now a known drop-in replacement for the speed sensor (as of January, 2023, this has now become available), and fortunately, failures due to the speed sensor are not as common. We have only seen one example in our customer base of a speed sensor failing, and it is replaceable just like the gear position sensor, and the re-learning of the transmission is also the same.

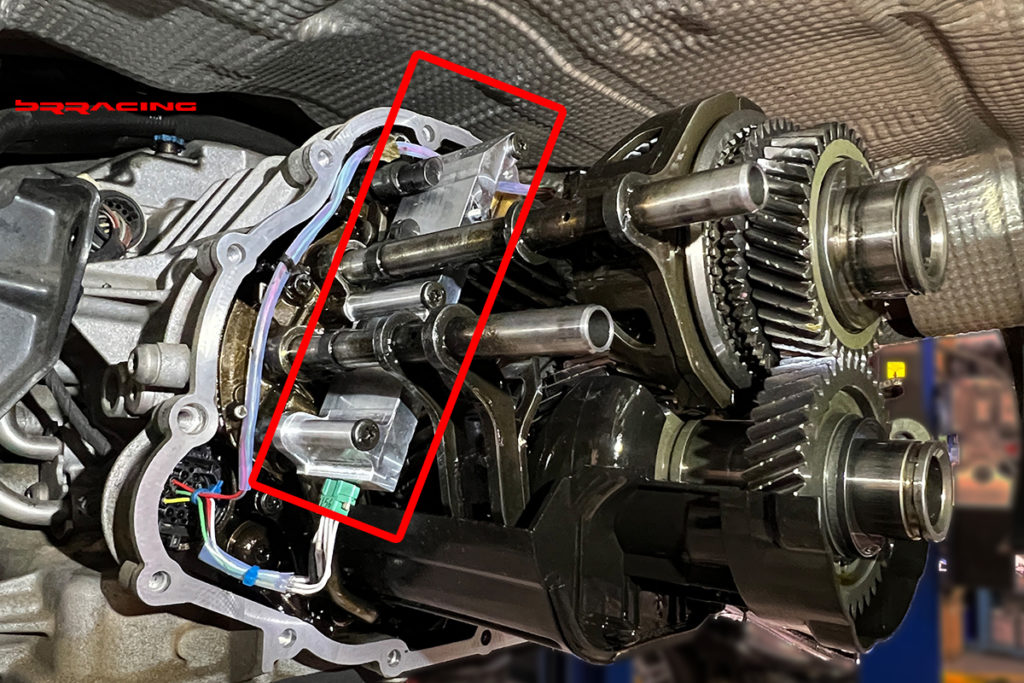

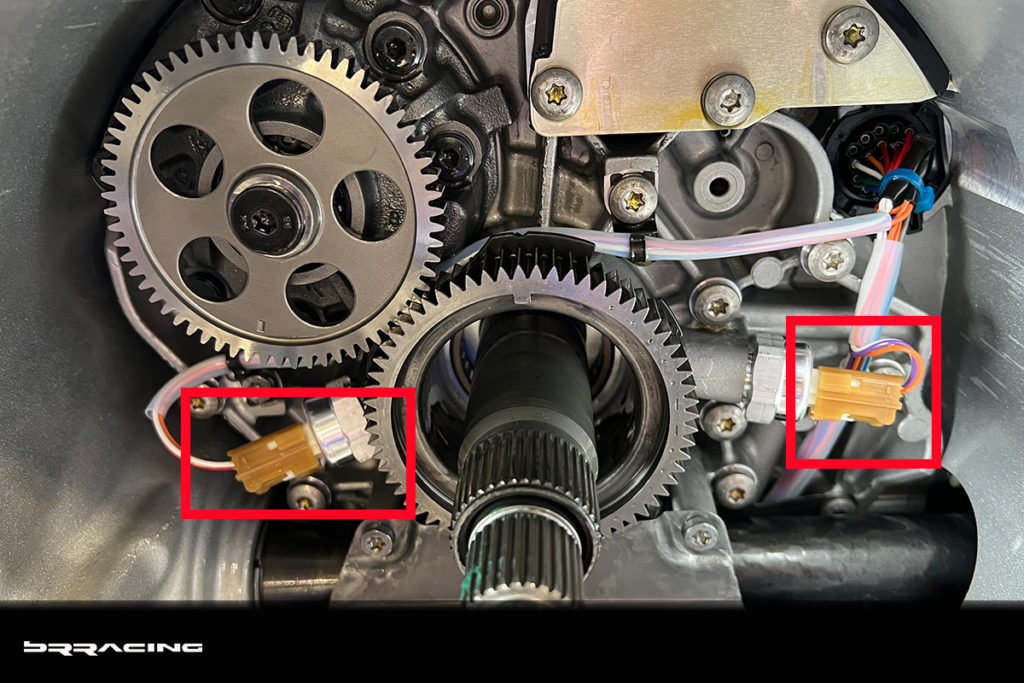

Unfortunately these sensors (Position and Speed Sensor) are located within the gearbox itself rather than the hydraulic section, and in order to replace them, the gearbox must be separated. The picture below shows the location of the gear position sensor within the Porsche 981 Boxster S PDK (tall shiny aluminum rectangular piece noted by the red box). You can see the black magnet appendages that are attached to the gear shift rods in the picture. As the rods are hydraulically moved back and forth the location of these magnets are sensed using a magnetic field sensor. These sensors then output a pulse width modulation signal proportional to the shift rod location.

The output of the sensor goes to a connector that is accessible outside the transmission. We find it hilarious that the factory trouble shooting guide states that gear oil leaks at this connector are caused by a damaged connector O-ring (a 50 cent part) and the remedy is to replace PDK transmission. Really?

Speed Sensor

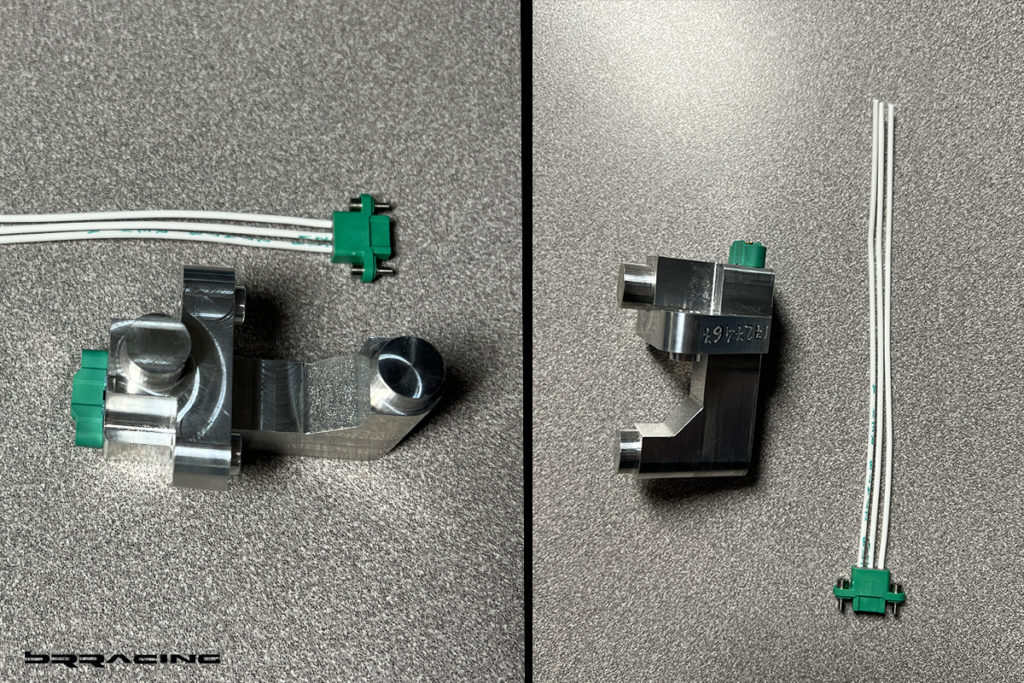

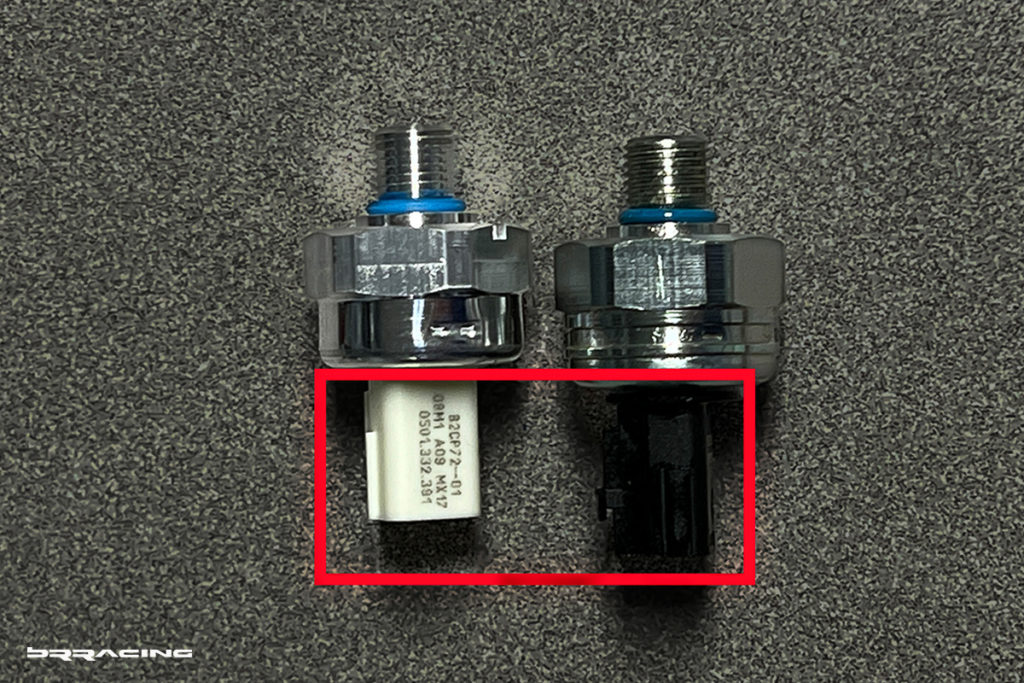

This part has very few failures, and until January 2023, there was no replacement…..but now there is. The original speed sensor is a plastic unit having two magnetic sensors (see pic below).

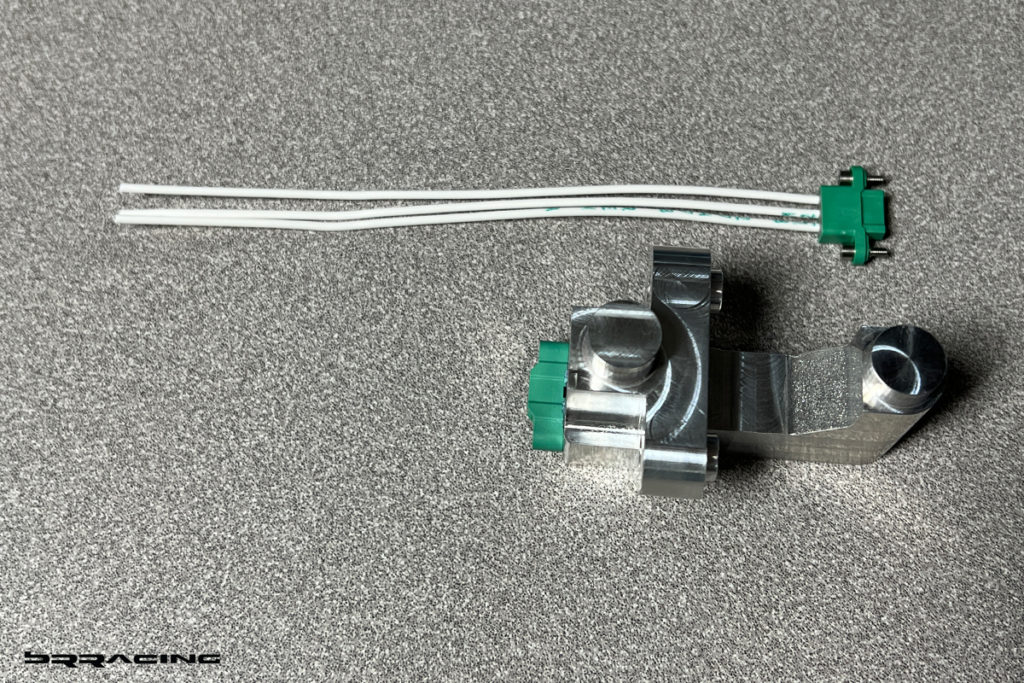

New, aftermarket PDK transmission Speed Sensor below:

The new aftermarket sensor is made of aluminum, to offset what we believe is the main reason the sensor fails…the plastic deforms over time, allowing it to not hold the exact position to the shaft, and the readings therefore are off, and errors are recorded. The new sensor mimics the original in function, but will be more robust.

Clutch pressure sensor failure

These are another two sensors that provide feedback to the transmission control unit regarding clutch engagement. They perform a similar function to the gear selection sensors in that they tell the control unit that the clutch is receiving fluid pressure when commanded by the solenoid. If one of these sensors fails the transmission control unit will think a clutch is not operating properly. Problems with these sensors usually show up as a P1706 fault code though there can be others.

These sensors reside behind the clutch and require transmission removal to replace them. Further, the clutch must also be removed (which isn’t hard if you know the trick, but also requires yet another special tool to be developed).

You can see the two sensors located behind the DCT clutch unit when the clutch has been removed from a PDK transmission; these would normally be hidden behind the clutch. (For reference the gear in the upper right hand corner drives the PDKs clutch fluid pump.)

Here is a pic of the DCT clutch assembly before removal:

There is another contributing failure we have seen….the internals of the DCT clutch assembly leak…good news is that the assembly is a replaceable part. See pic below of another DCT assembly, and you can see the grease / fluid evidence around the outer perimeter. The DCT clutch assembly can be pulled, and replaced.

This is the view once the DCT clutch has been removed –

Here is another view of the pressure sensors (with them highlighted)

Next, we found that there has been an upgrade, or evolution, of the pressure sensor. Notice in the pic below the difference. Same function….newer part.

Heres the cutaway view below showing one of the sensors (red arrow) and the associated connector accessible on the outside of the transmission (green arrow). As with the gear shift sensor, you can likely perform some T-shooting via measurements at this connector. Note that this connector is the same one also used for valve body solenoid connections. This is the same round connector in the previously shown Porsche valve body drawings, the two small square connectors seen in that drawing are what attach to these clutch pressure sensors. On 991/981’s PDKs with the locking differential option there is also a third pressure in this same area, the 997/987 PDKs don’t have this third sensor.

The PN is 9G1.307.385.05 and it does appear in 997.2 PDK parts lists but the location is not shown in the parts diagrams. Further, it’s also a ZF part like the valve body solenoids and the OEM PN is ZF 0501 326 481. (confirmed the same sensor is used in 991.1 PDKs even though it’s not listed in the parts diagram.)

This same sensor is a replaceable part used in the Panamera PDK so it should be available for the foreseeable future.

Once the transmission is out of the car, the clutch can be removed to get access to the sensors using a homemade slide hammer. They don’t explain how to reinstall the clutch but it can probably be pressed back on using a bolt and stacked flat washers. There may be a trick to aligning the clutch in the spline so its probably a good idea to document the orientation of the clutch prior to removal.

Believe it or not, that is it as far as the electronics inside the transmission. All of the smarts are located within the Transmission Control Unit which is remote and separate from the transmission. When people say they had to have their PDK reflashed they are talking about the TCU, not the transmission itself.

Clutch failure

Last but not least is potential failure of the clutch itself. The good news is that these clutches have proven to be very robust and don’t fail often. The failures that do occur are usually on heavily built engines (e.g. 30% + power over stock) with just too much torque for the clutch plates. At these high torques the clutches slip resulting in highly accelerated wear. There are replacement heavy-duty track clutches available for the PDK from Dodson Motorsports, but they are very expensive. We have built a couple of these transmission / clutches, very robust, very expensive.

The clutch truly is a sealed unit and is not serviceable. There are different clutches for the Carreras (rated at 450 Nm) and the Turbo (rated at 700 Nm). We could not find any OEM clutch suppliers and only found one Chinese aftermarket supplier.

Conclusion

To be blunt, I think Porsches approach to treat the sealed PDK transmission as a replaceable component is wrong. There are many relatively inexpensive, readily replaceable parts in this transmission that could be serviced by qualified shops. Failure of these parts likely makes up a large majority of the PDK transmission replacements. There are other car manufacturers that have taken this same position (think about MINI Cooper transmissions and their issues that we have overcome as well).

To be fair, Porsche dealerships do replace valve bodies on the PDK but there is little information on this available to the general public.

The good news here is that we have been able to repair the PDK transmissions now on 911’s, Boxster, and Caymans.

NOTE: pretty much every repair discussed here will require PIWIS service / transmission calibration (sometimes multiple iterations of the calibration) prior to being back on the road. Replacing the valve body needs a transmission calibration, as does installing a new clutch. Any repair that removes the valve body (even if not replaced) will require a PIWIS for refilling the transmission. A Durametric can read the codes but it can’t perform the PDK commands. So hopefully anyone affected is on good terms with a competent independent shop that has a true Porsche PIWIS system who can take care of this for a reasonable price. Also note that you’ll likely have to flatbed your car to the shop for the calibration and/or fill procedure if you DIY the work.

So is opening the PDK gearbox to replace parts feasible? It absolutely is. ( On a scale of 1 to 10 in terms of doing this work, the PDK repair is about an 8, not including the development of all the special tools). Possible, yes, easy, no. Care needs to be exercised in the repair, as many of the bearings, nuts, and other parts are NOT available, so, if damaged, then the transmission becomes a paper weight.

Next steps

Compile transmission fault codes to cross reference against likely part failure and the repair process.

Great information.

Another Scenario – Software

A Panamera PDK transmission suddenly started slipping in 1st and 2nd gear while leaving a parking lot. It can’t pull a hill or even go over a speed bump without momentum. In order to get into 3rd gear, the customer couldn’t go past 2000 rpm and had to baby it until you get into 3rd. Exceeding 2000 rpm before reaching 3rd gear will only trigger a transmission fault and go into limp mode. In order to drive, they had to keep the rpm below 2000 on flat ground until they reached 3rd gear by driving extremely slow like 1 mph and increase speed by 1 mph every 2 seconds until it reached 16 mph. It would go into 3rd gear when once you reach 16 mph. At that point the car drove perfectly all the way through to 7th gear.

We were told by the Porsche dealer that we would likely need a new $25k dollar transmission or a new $2800+ labor valve body at a minimum. However, I called another Porsche dealer and was told it could just be a software issue requiring a simple PDK re-calibration and relearn.

We tried the software update / relearn / re-calibration fix and it absolutely fixed the issue. 1 hour labor and it saved the customer almost $25k.

There is also a command hidden somewhere in PIWIS tester that can increase the clutch pressure to eliminate slipping which is especially useful if your PDK is near 100k miles and may need readjustment due to being worn down a bit over time from when it was new. Always more to learn, and there has been great sharing of info between shops and users to build this missing knowledge base.