1988 PORSCHE 911 Carrera – Rescue

(The picture above is after the rescue was complete)

As our business continues to grow, so does the breathe of projects that customers have us tackle for them. In this case, it’s sort of a rescue…rescue from being stored in a garage for over 20 years. The car is a beautiful 1988 Porsche 911 Carrera. 2-door coupe. The owner had put it in a garage, covered it (thankfully, stored in California), and just let it sit. Time flies by as it does, and before the owner knew it, 20 years had passed. The car only had 28k miles on it.

Now the time had come to resurrect the car, and bring it back to life. But, what needed to be done? What needed to be fixed, or repaired, or replaced? This is the most important aspect in a resurrection….what is the plan, the desire, the objective. For our customer, the objective was indeed to resurrect, but not restore to new. He wanted it back to the way it was when it was parked / stored, and get it back to full running, usable condition.

The great news here was the car had been stored in California, in a garage, and w a proper cover. The exterior and interior were nearly flawless. But, the running parts (engine, electrical / battery, suspension, tires, fuel system), were all dead, and indeed in need of major help. The rescue was performed at BRracing’s Campbell location.

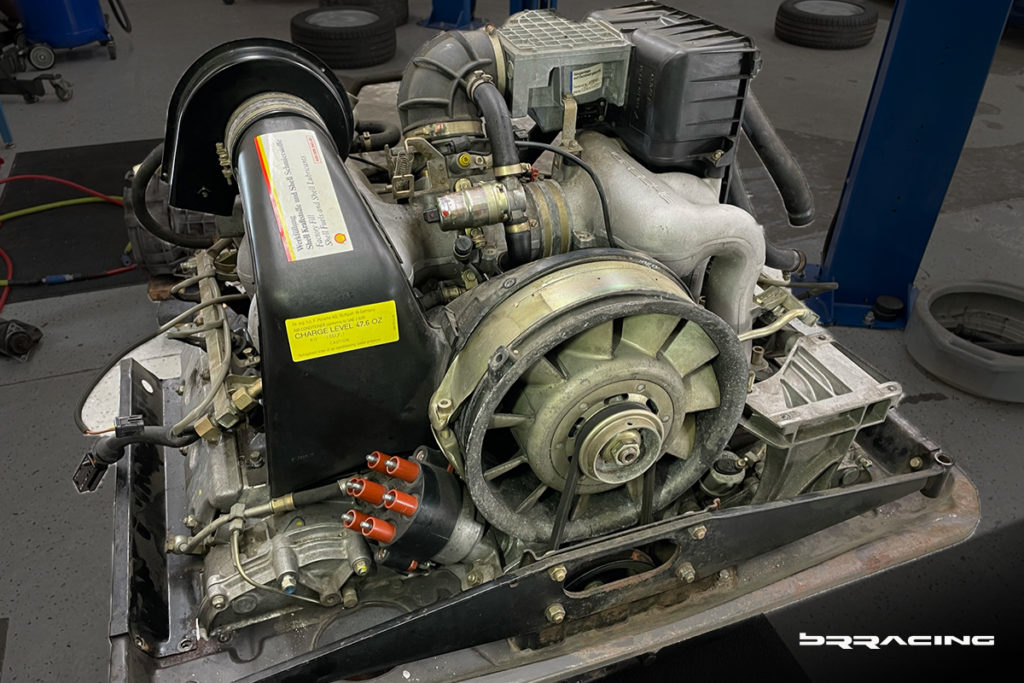

To get started, the basic is the full inspection of what we have to work with, work on. We knew the battery was dead, and that got replaced right away. We primed the engine, and got the engine to fire….but, massive volumes of smoke came from the exhaust. We knew what that meant…the engine would have to come down, out, and a complete rebuild. We also drained the fuel tank, and examined the state of the fuel, and the bottom of the tank. Tires were dead, the paint on the wheels chipped and peeling, so those came off for future attention.

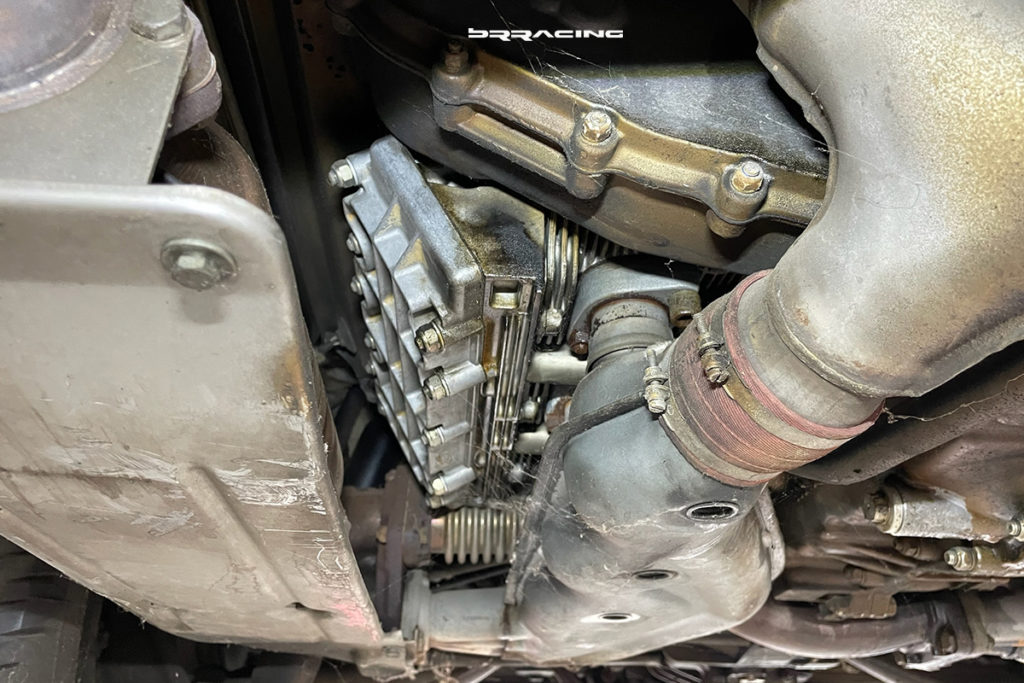

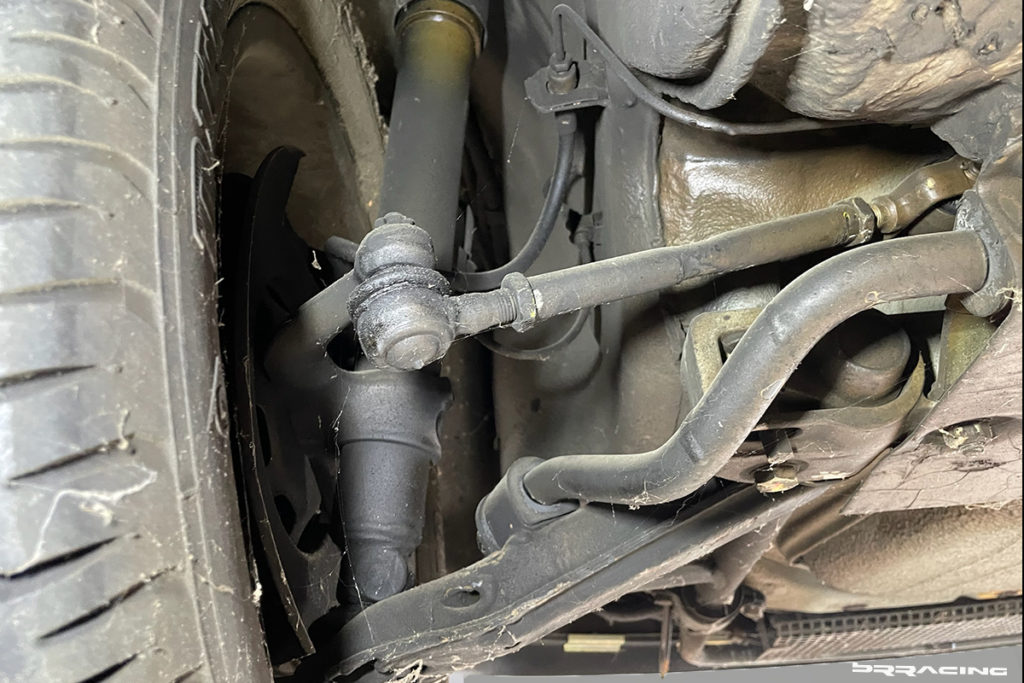

Quick visual inspection showed that the bugs and spiders had made full use of the car as a home for the last couple of years. We would quick eradicate all infestations. Oil leaks were present almost everywhere, suspension dry, bushings torn, cracked. No major corrosion, just evidence of what sitting and age will do.

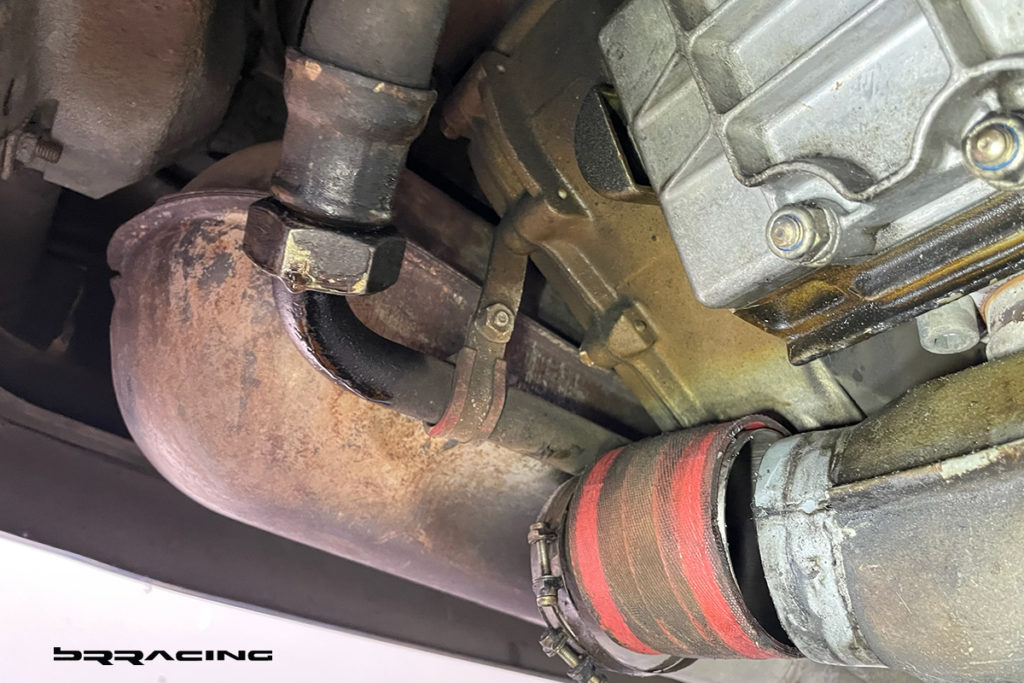

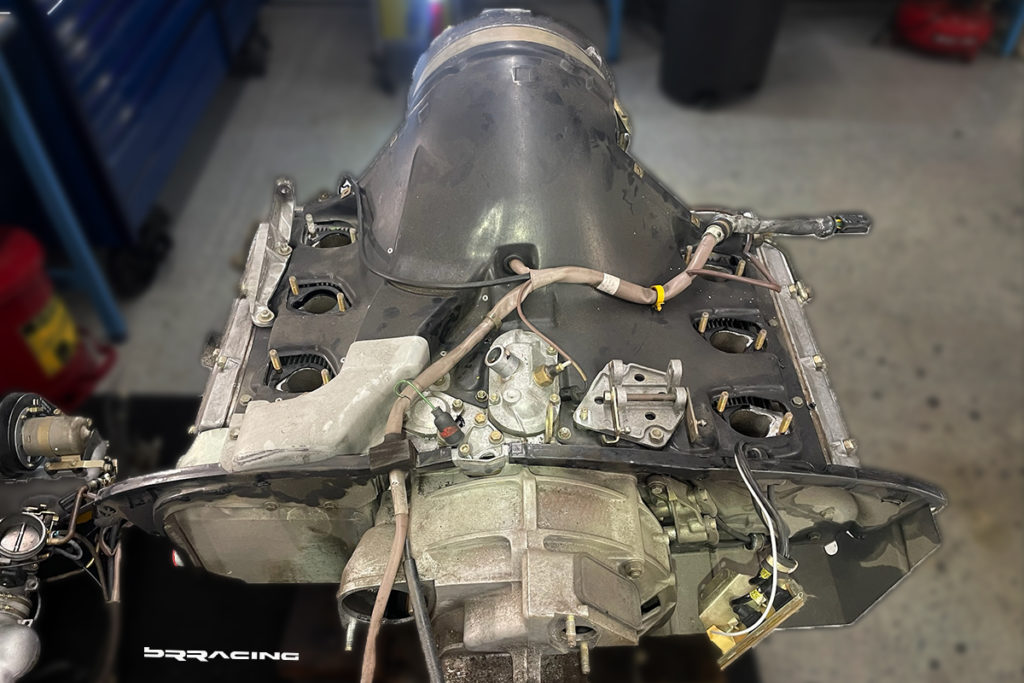

After dropping the wheels / tires, next was to prepare the engine and transmission to be dropped out of the car.

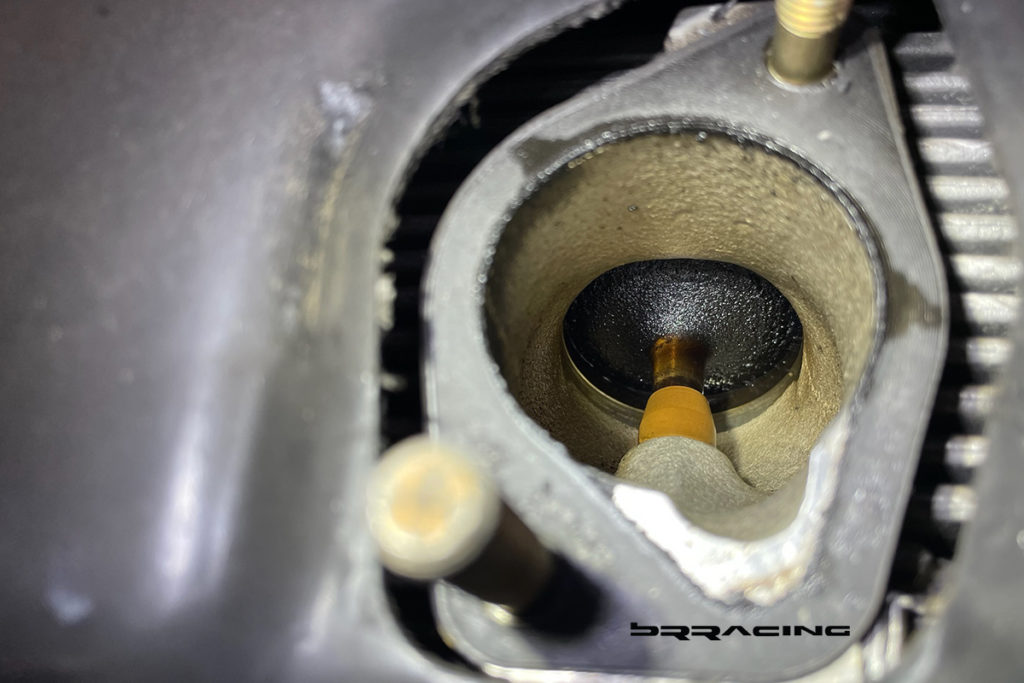

The oil in the intake system, and the heavy amount of smoke from the exhaust are the telltale signs of what’s to come.

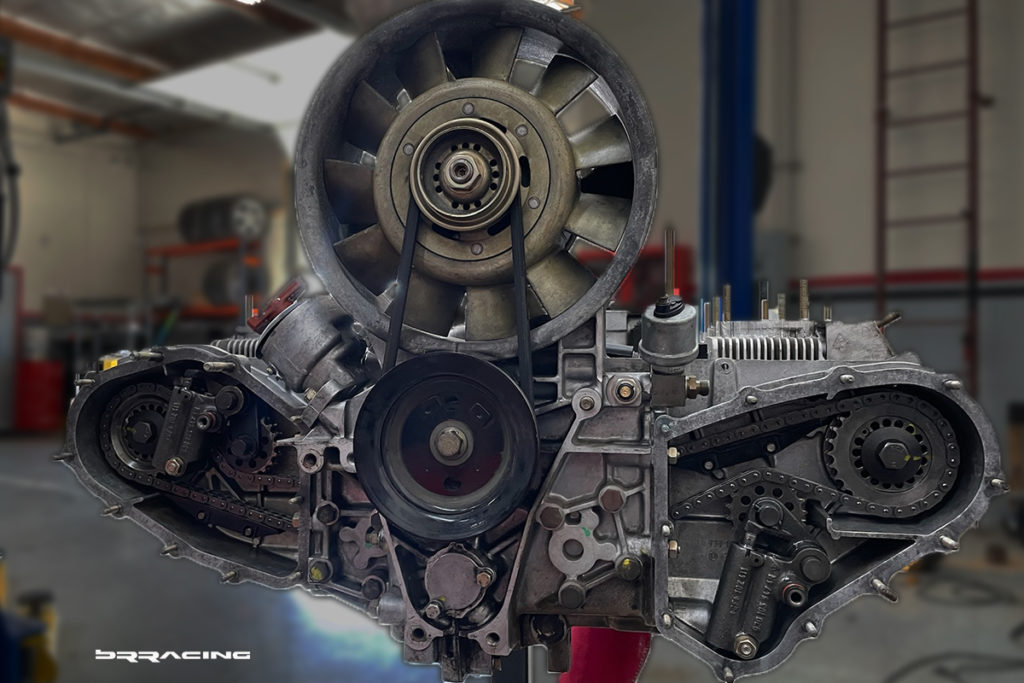

Lots of work ahead. Engine and transmission come out.

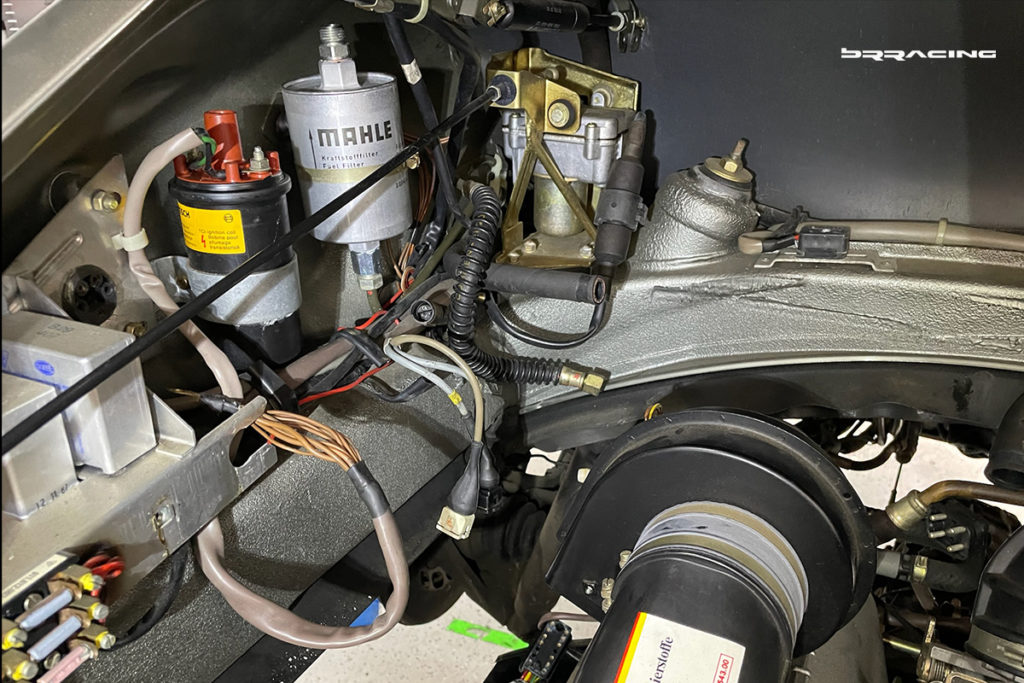

With the engine and transmission out, further inspection can be carried out on the car itself.

Obviously, the insulation is toast, but most of the wiring, electrical, and fuel system seem to be in usable shape. Evidence of prior repairs are present, and will need to be tended to during the rescue.

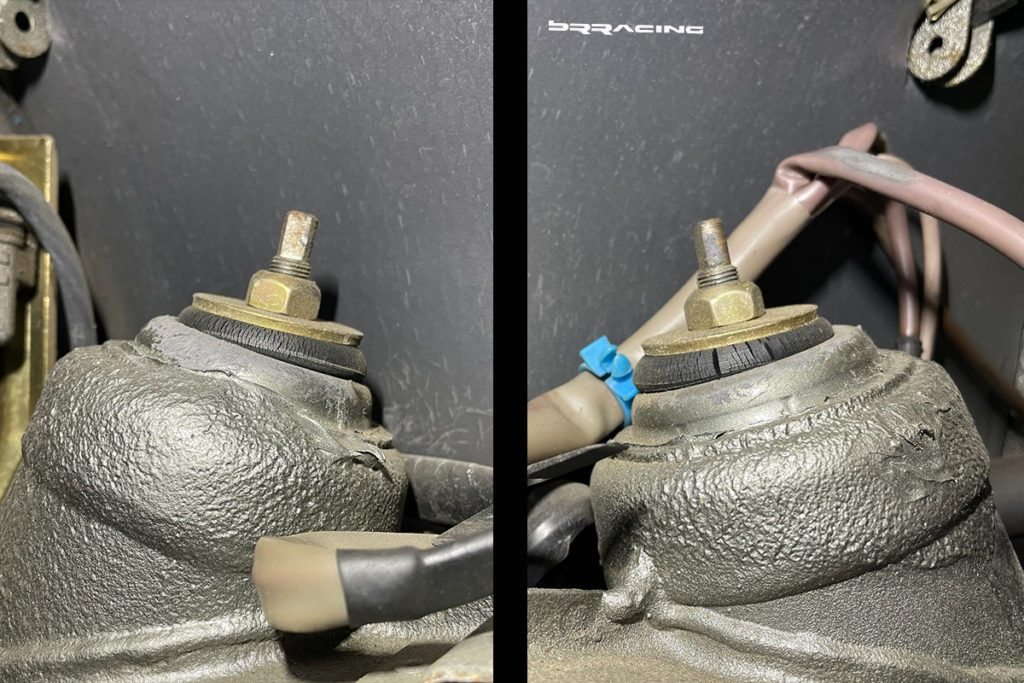

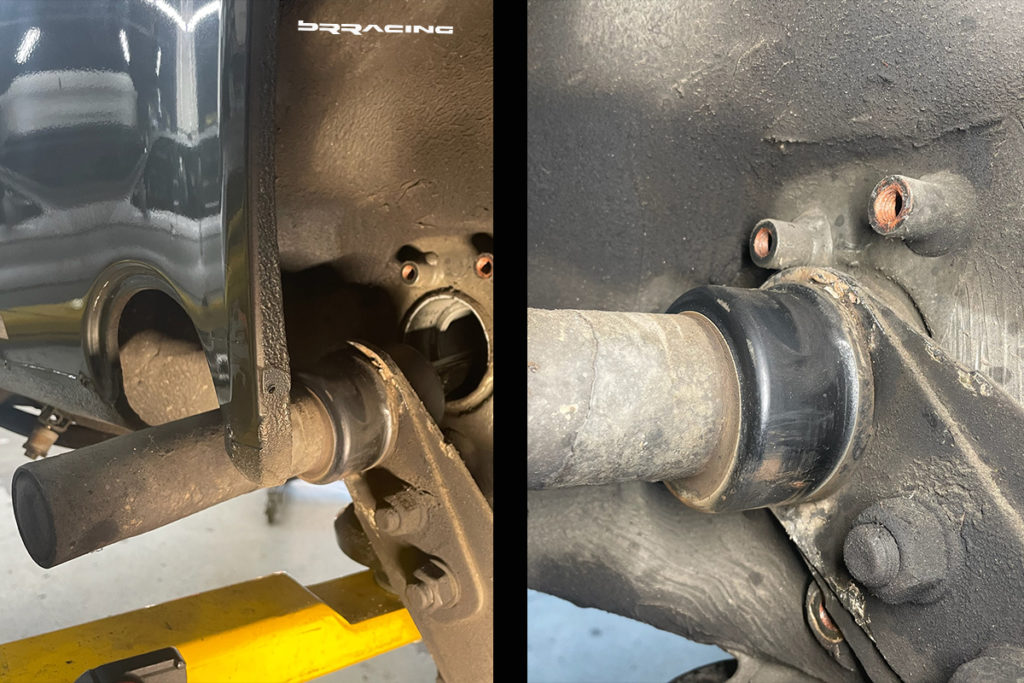

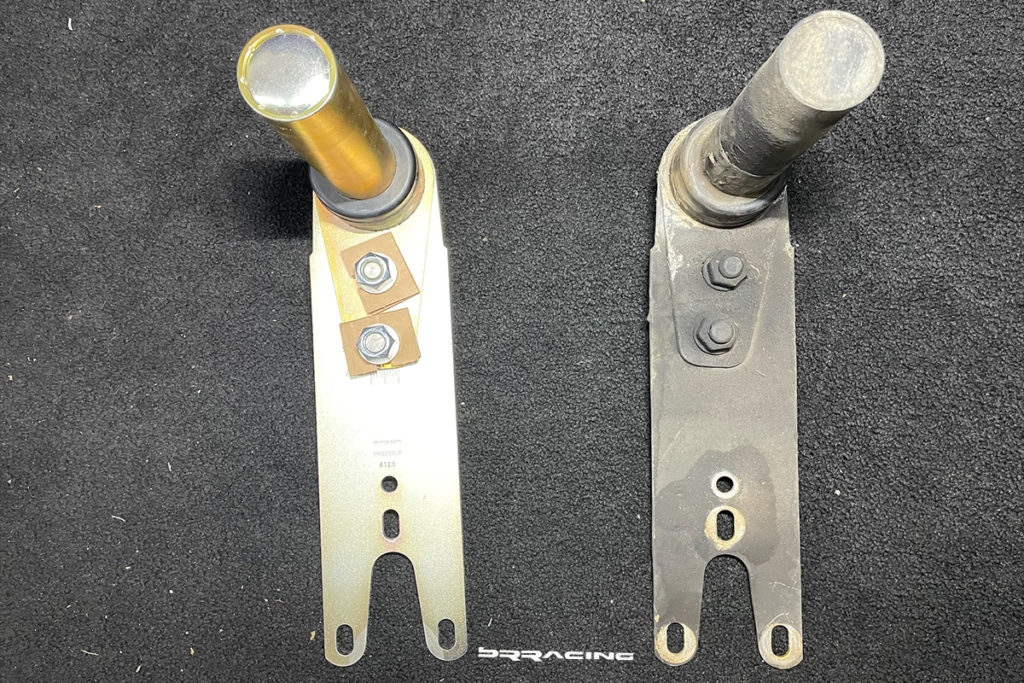

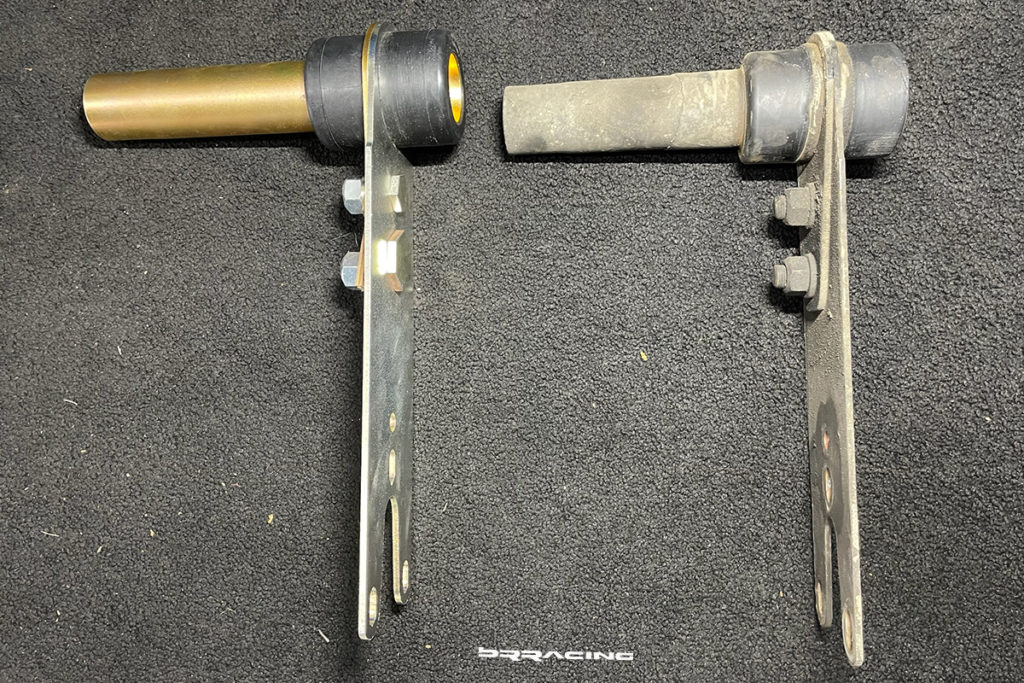

With the engine and transmission out, full inspection can be completed on the suspension as well. As most know, rubber does not age well, especially on a car that is nearing 40 years old. This can most easily be seen in the rear shock mounts. The deterioration is evident in both the rear and front suspension. Much work to be done here…must all come out, bearings be inspected and tested, almost all bushings replaced. All surfaces cleaned, polished, lubed before new parts to go back in. Shock mounts, sway bar bushings, torsion bar mounts, swing axles, steering tie rods, ball joints, main wheel bearings, the shock themselves (leaking), axles, CV joints / boots, sway bar end links. The inspection shows the brakes to be in good condition

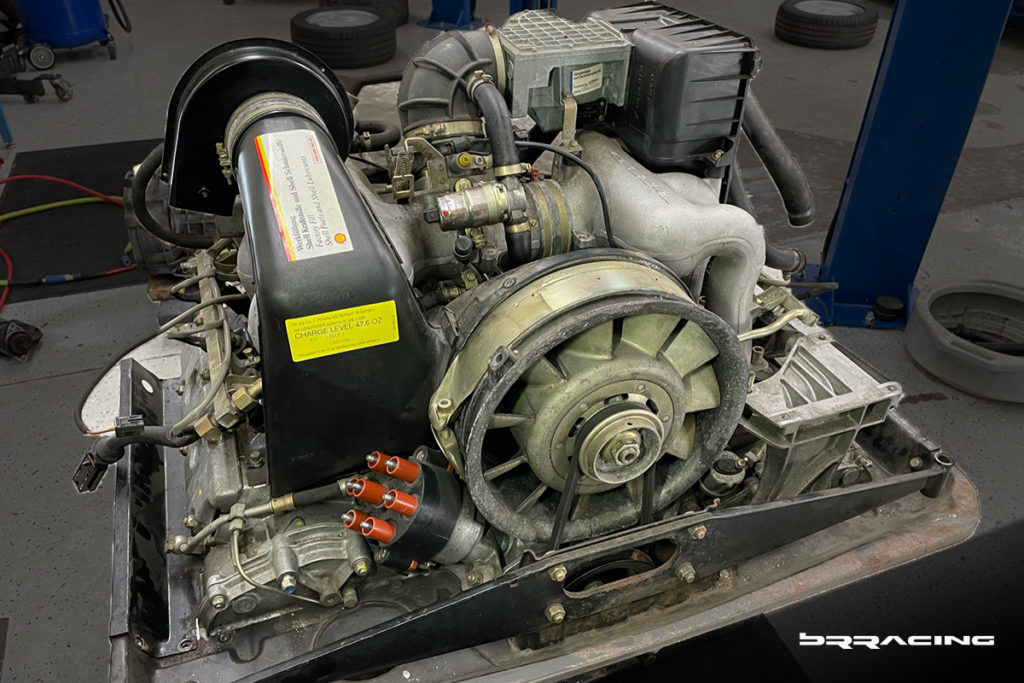

As with all “rescue” or “semi-restorations”, the scope always seem to creep. But, we had just done this exact project for two other Porsche’s (see our other project file for another 1988 rescue, and the “humpty-dumpty” 1983 911 project. As a result, we knew what the likelihood of what we would find from the inspection and testing would show. We now need to peel the onion a little farther, and get the engine and transmission apart, and stripped down.

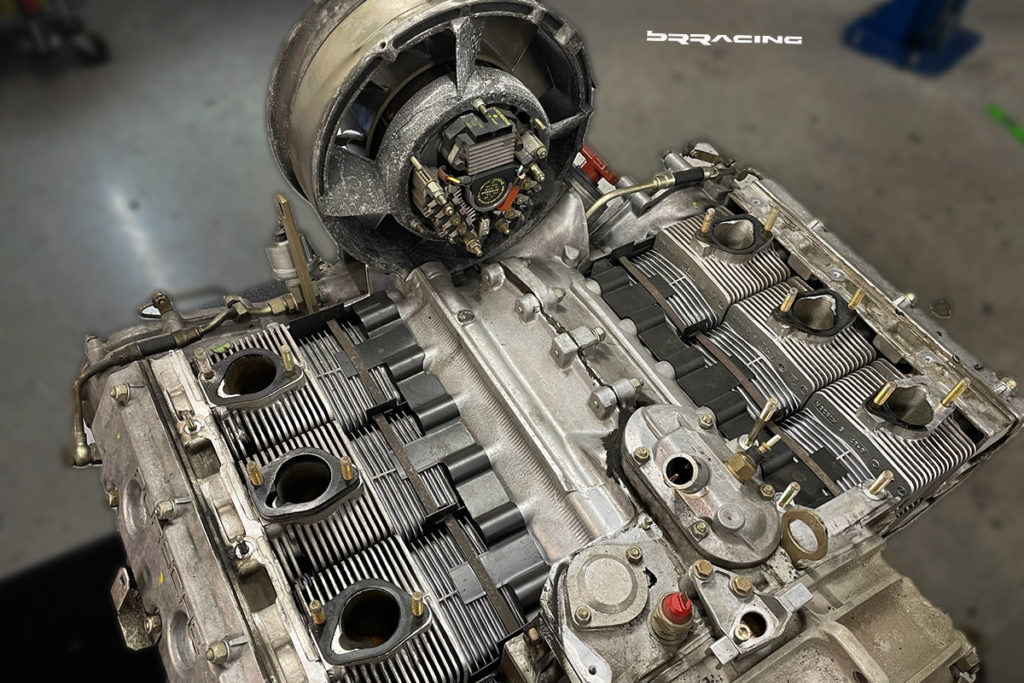

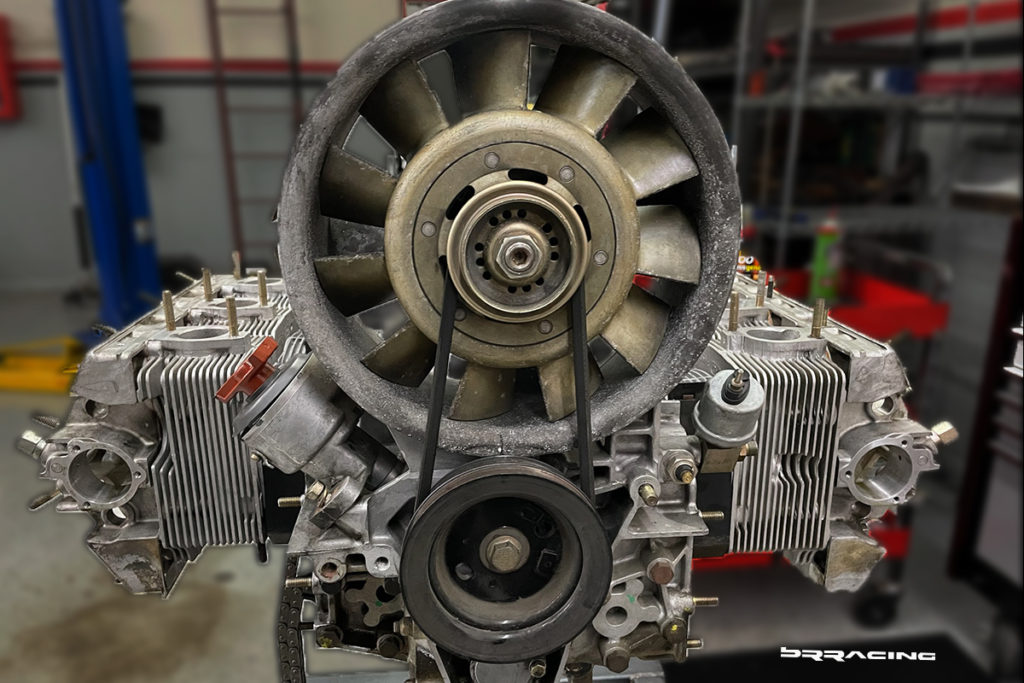

Corrosion present on the main center engine fan, and several of the surrounding pieces. This we can resurrect without having to replace.

On our other 911 restorations, we have seen a lot of corrosion on the interior heat shields / guides. This engine looks very clean in that area, but more corrosion evident on the back side of the fan motor.

We have several of the newer tools that make restoration straigh forward. Here we subject the fan housing to “vapor blasting”. If the corrosion were more intense, we can also perform “soda blasting” to remove more stubborn deterioration.

Too much oil residue inside here..implying that we have some internal seals that will need to be replaced. More surgery needed.

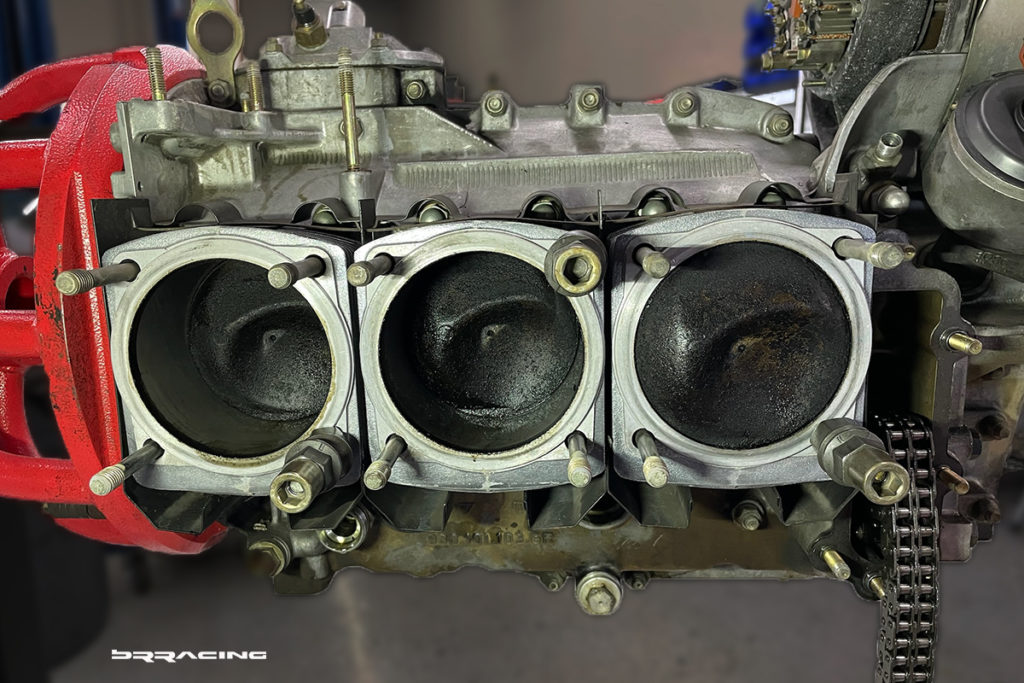

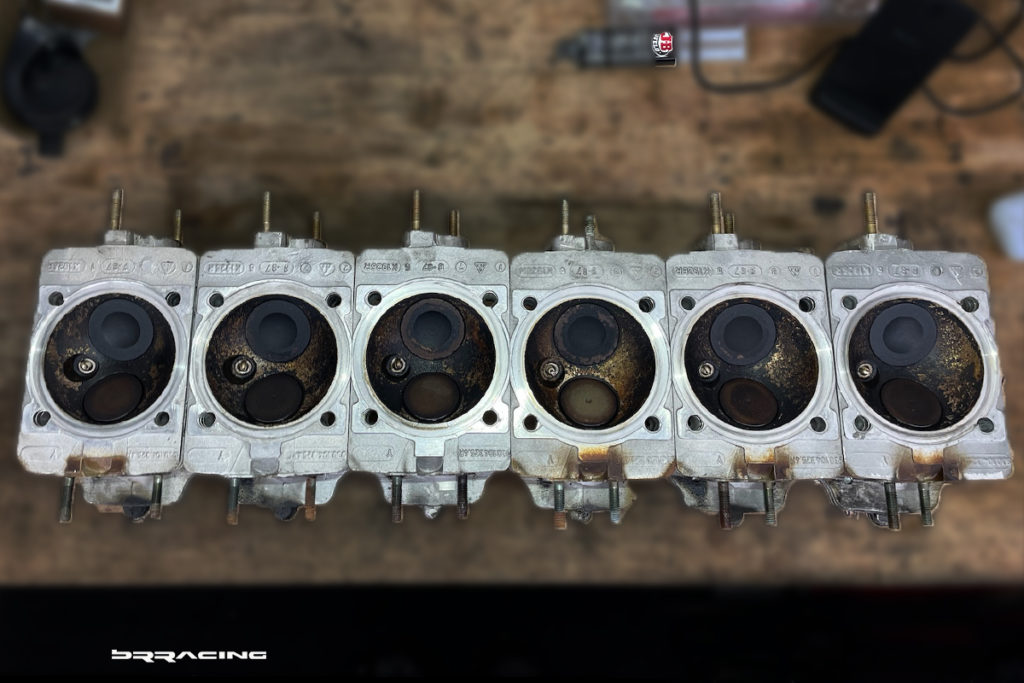

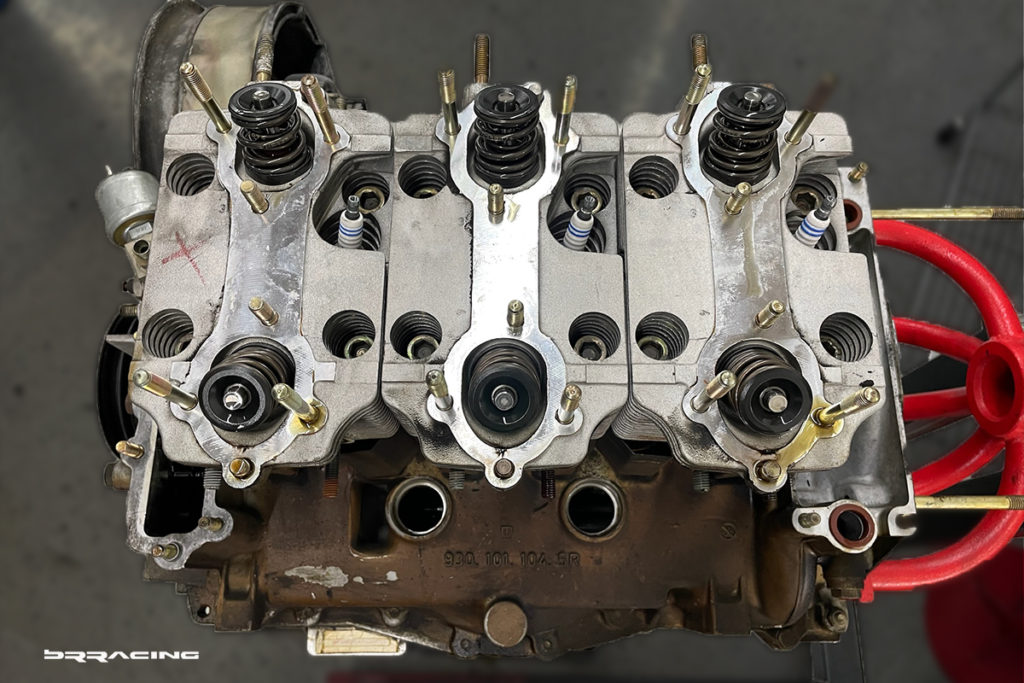

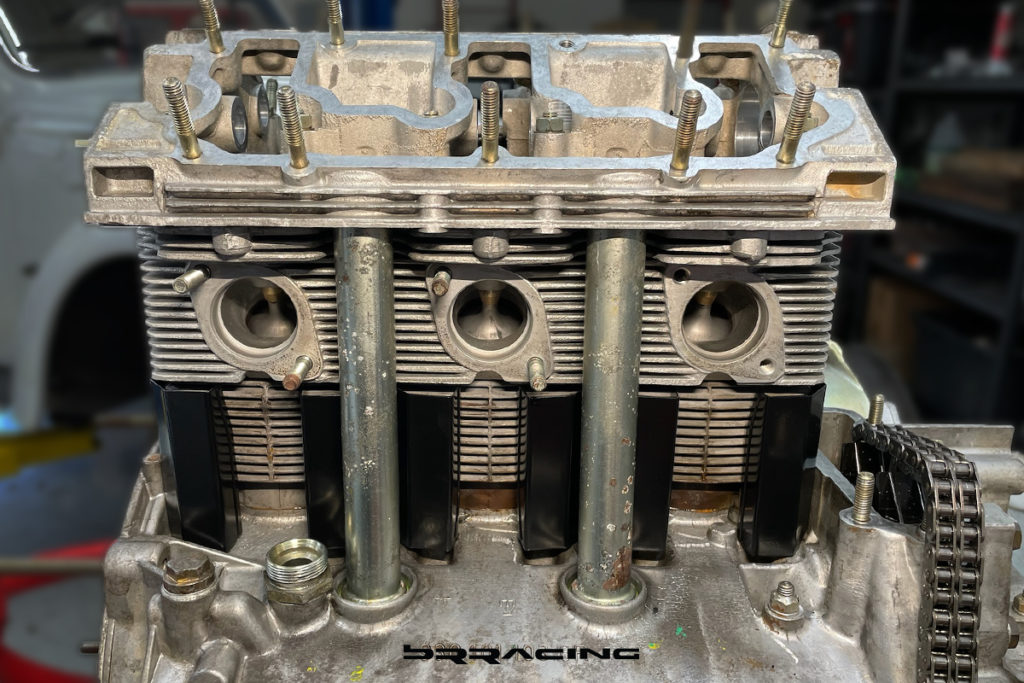

And here is the root cause of the smoking engine…the valve stem seals that have shrunk, and therefore, not sealing. This allows the oil from the head to seap into the cylinders and gets burnt off. Inspection of the top of the piston also supports this finding, and the fact that the cylinders held good compression, very little leak down, and the cylinder walls were pristine, all support the root cause being the valve stem seals. This means the heads have to come off, and be completely rebuilt.

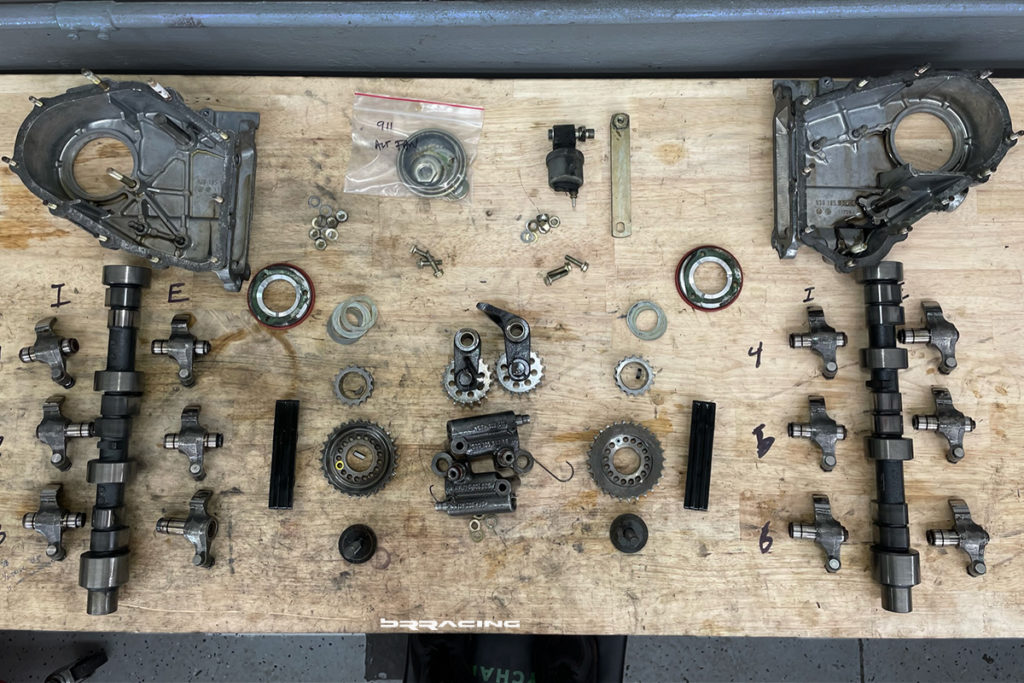

Inspection of all the other parts of the heads looked good. No unusual wear, rockers all good, cams good. Cases are partially corroded, but again, those will get cleaned up as part of the process and engine build.

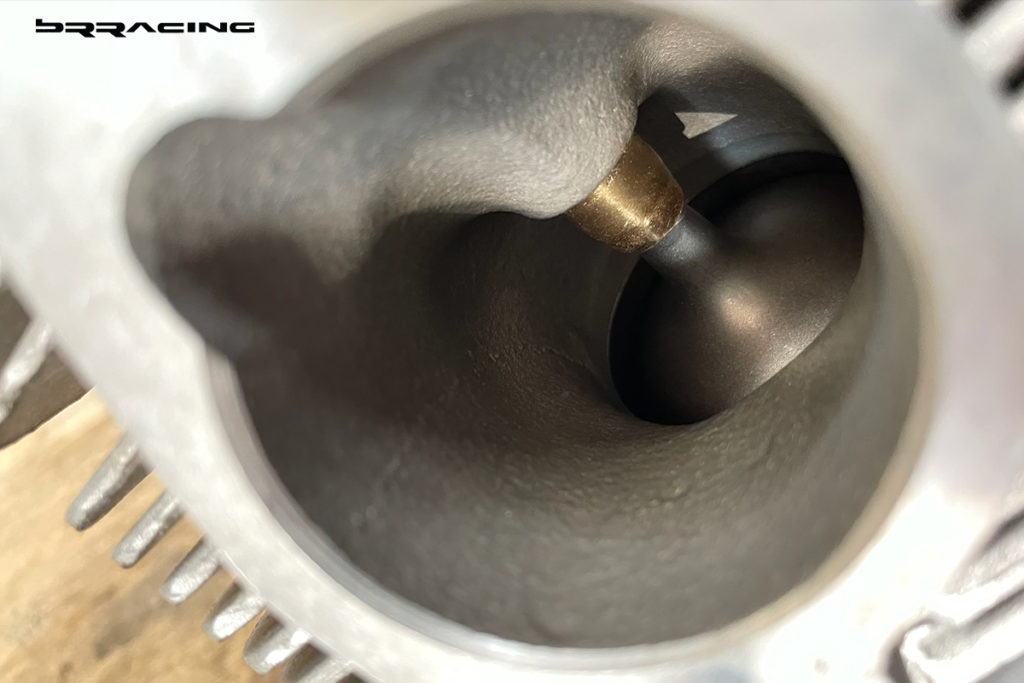

Had all the heads completely rebuilt, new valves, new valve stem seals, valve cut, pressure tested. No issues found.

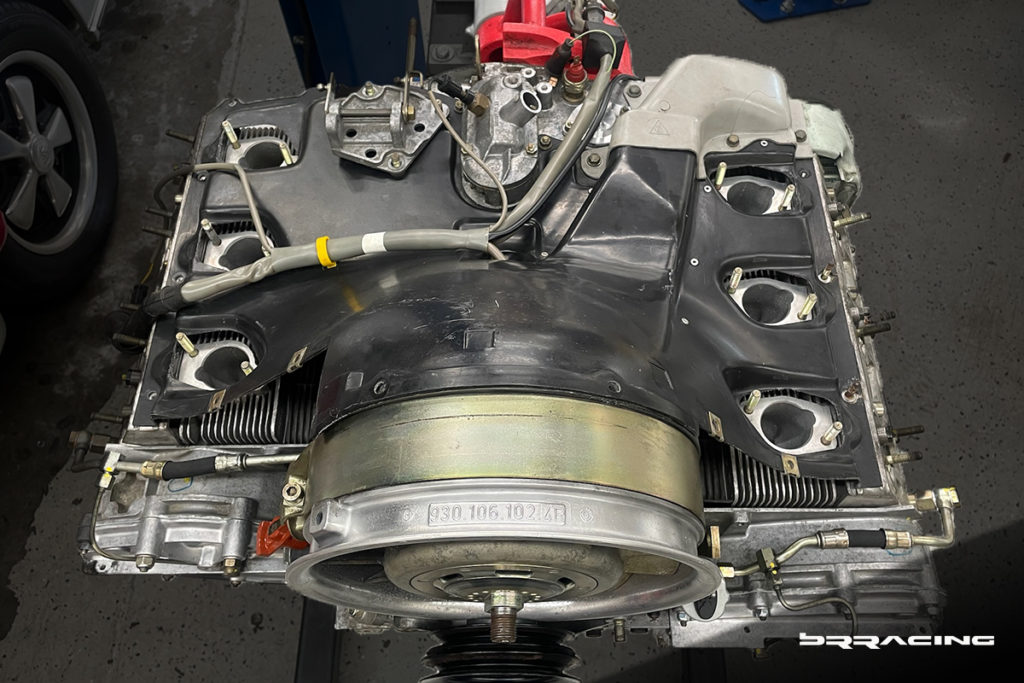

Had inspected and tested the core block, crankshaft, bearings. Since the objective is to resurrect and bring back to the same running condition it was before storage, we didn’t need to go deeper or farther. We weren’t here to bore, stroke, enlarge, lighten – one of the keys of a successful resurrection or restoration is staying true to the original customers plan / desire. Once we had the heads back, we could start the assembly of the engine again from the block out. Pulled all the old hardware, cleaned all the threads, installed new cylinder hardware, slid all the cylinders back on the block, installed the heads, and the cam carriers.

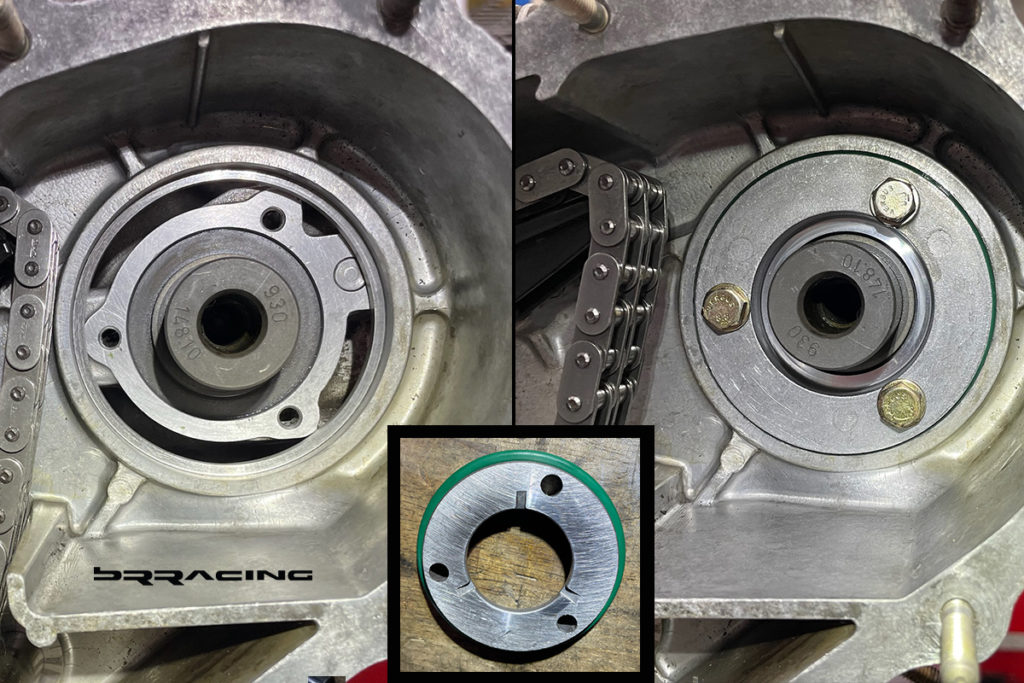

With the heads now on, the camshafts, rockers and head assembly could be completed. An example of the camshaft seals that needed to be replaced (given the prior evidence of leaking here as well).

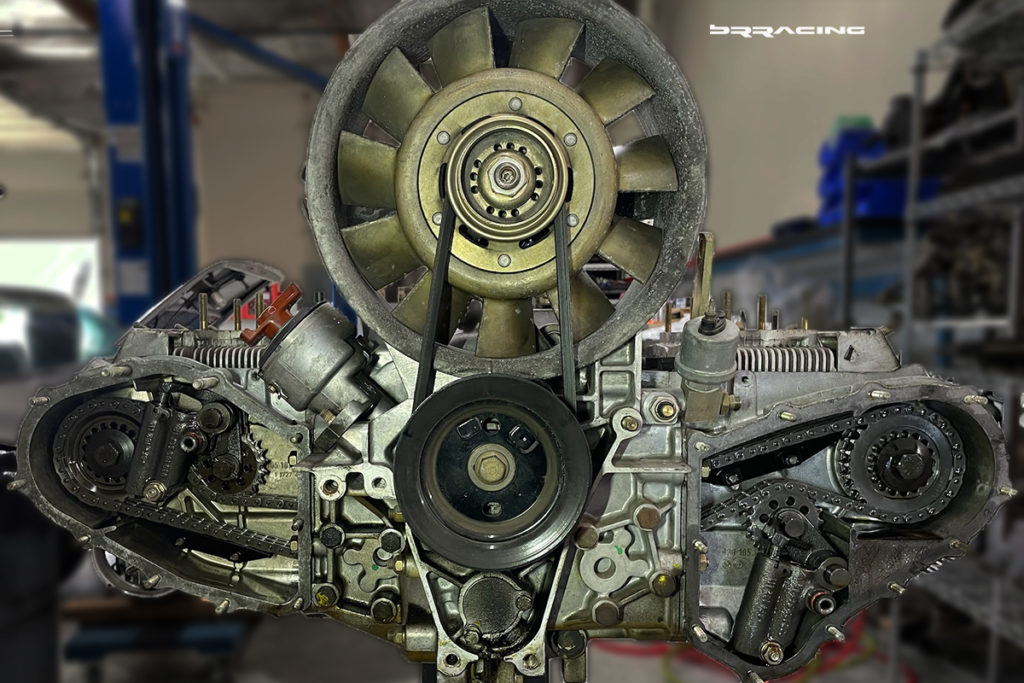

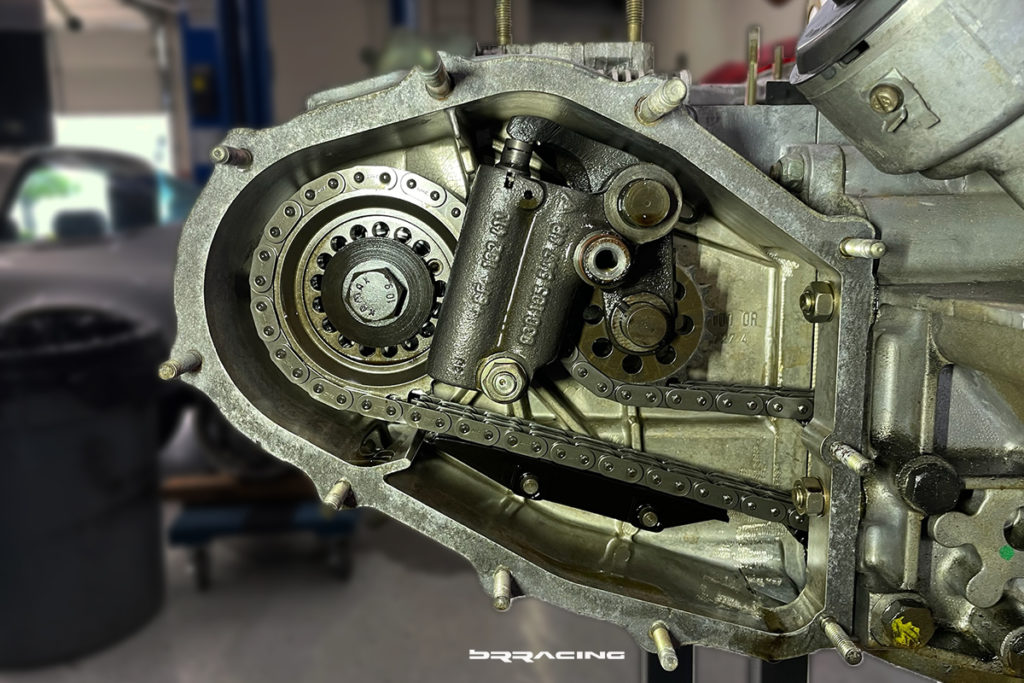

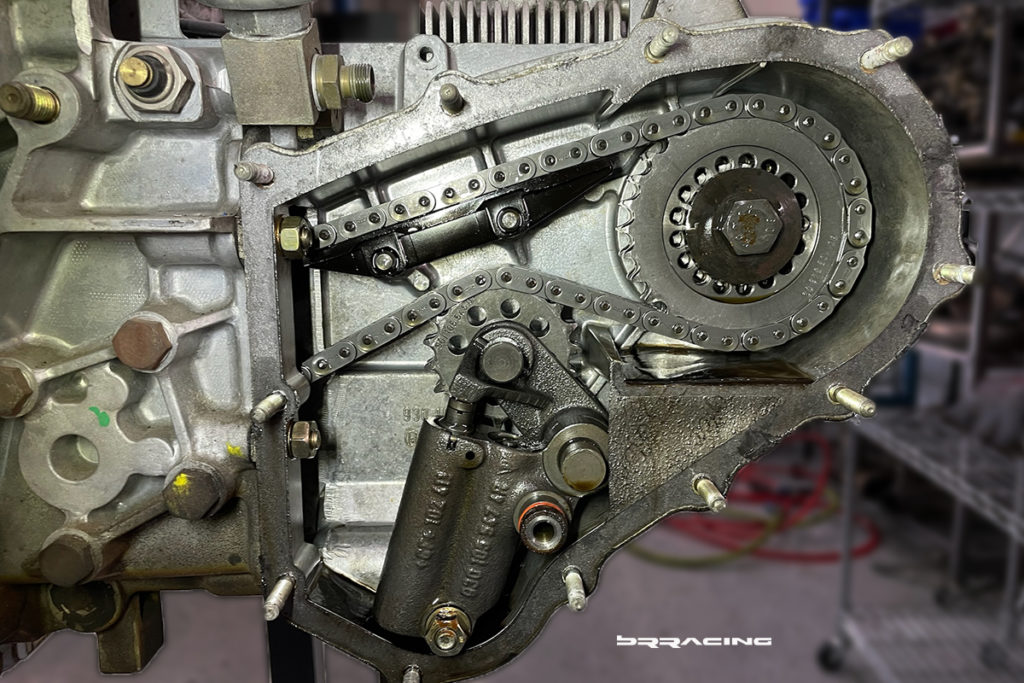

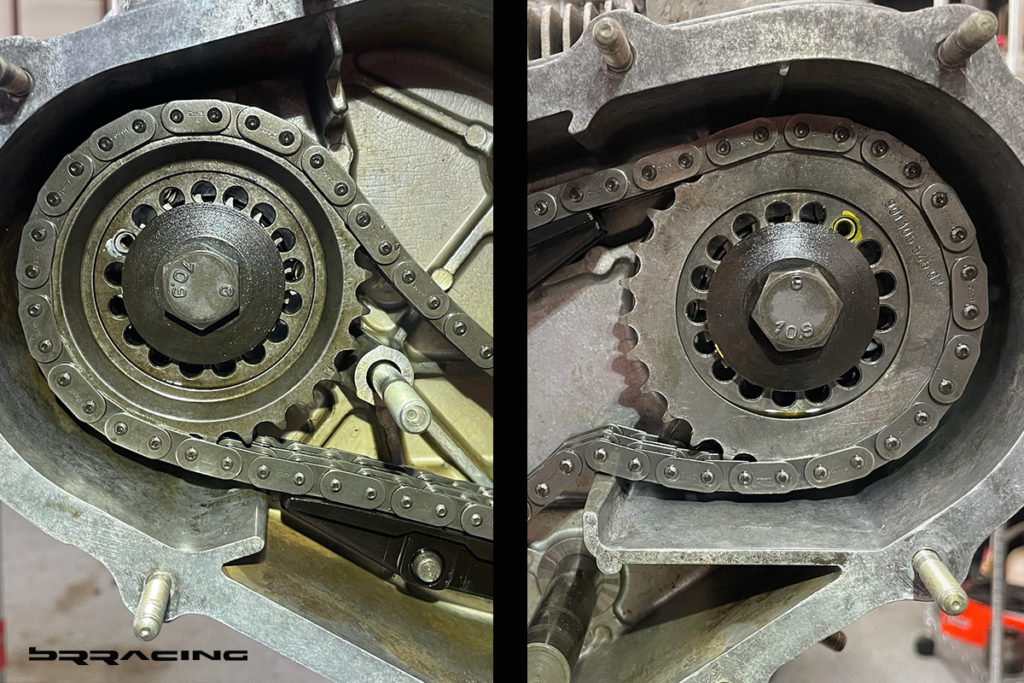

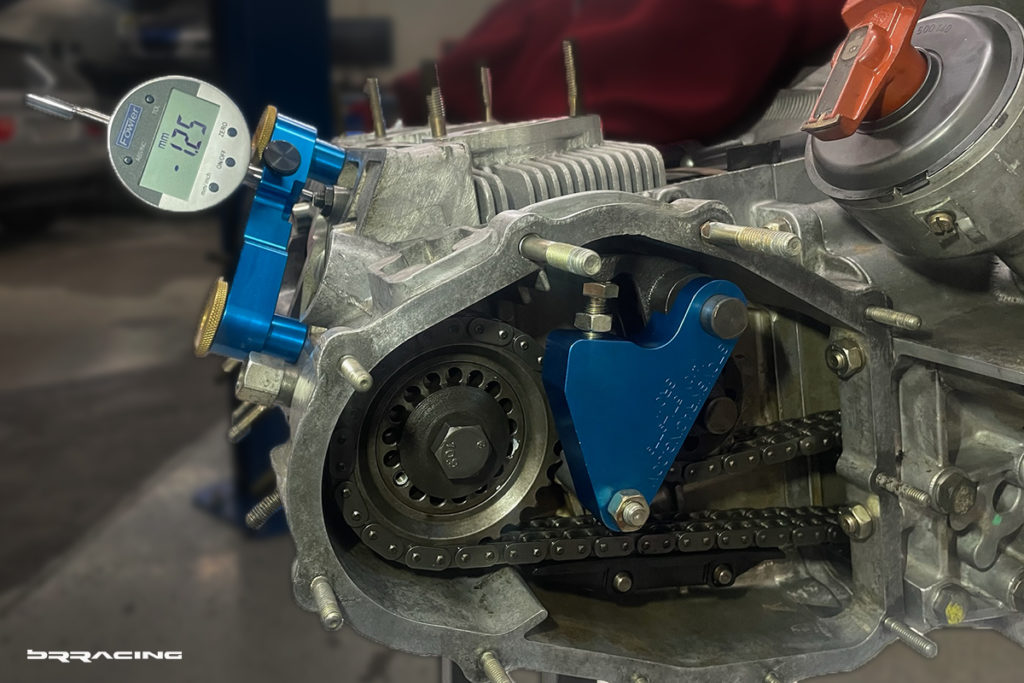

With the timing chains, guides, ramps, tensioners all in place, we could now work on the engine timing.

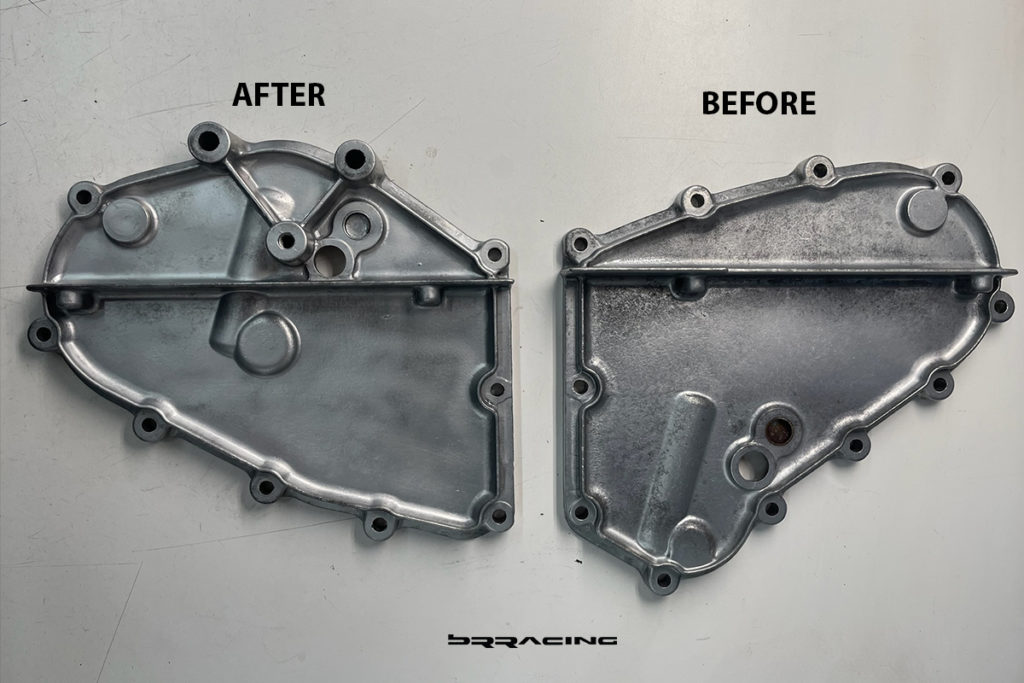

Ready for further assembly…cleaning, prepping the timing case covers

Ready for further assembly…cleaning, prepping the timing case covers

The bottom of the engine now complete, assembly could move to the top….which is a lot busier, messy. Intake manifold, oil lines, distributor cap, spark plug wiring harness, fuel injectors (w new seals), fuel injector rails, fuel lines, belts, covers, heater elements…

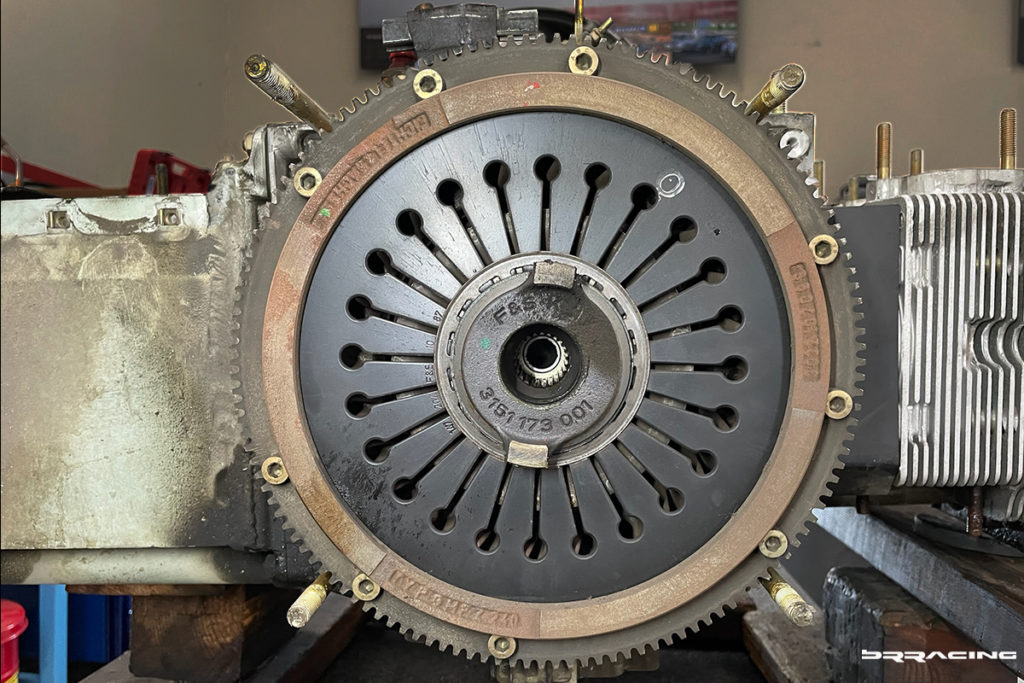

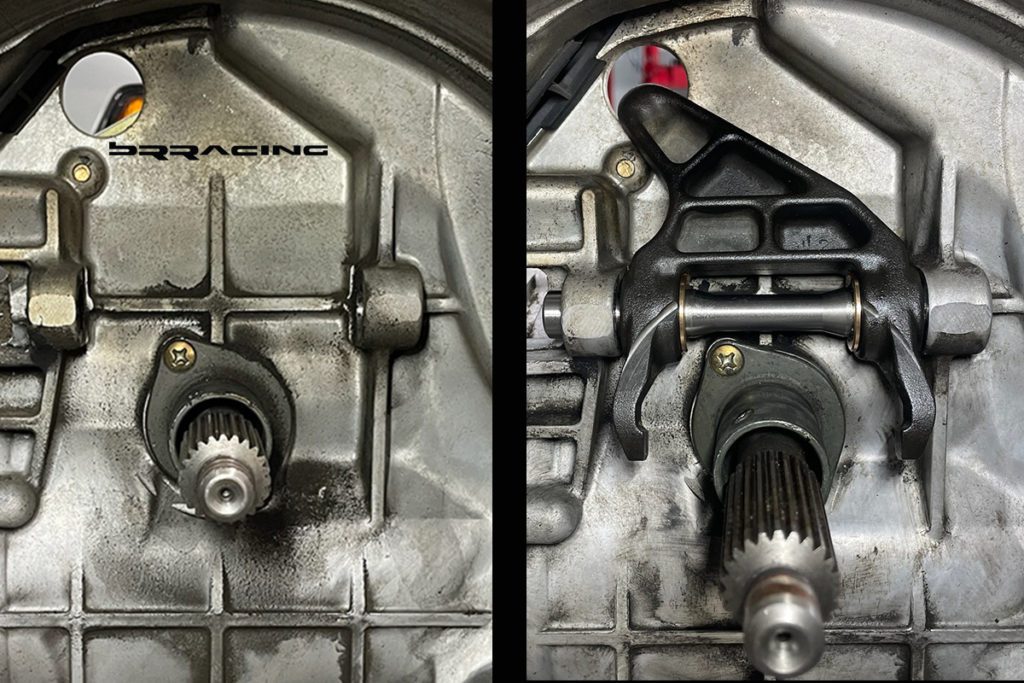

With the engine almost all back together, we now needed to turn our attention to the transmission, clutch, pressure plate, flywheel, clutch release arm. Both to dis-assemble and determine state of wear and need to replace. If the clutch needed attention, this is the perfect time to accomplish that.

The clutch, pressure plate, flywheel were in fine shape, no need to replace. But the clutch release arm needed attention, and got fully rebuilt.

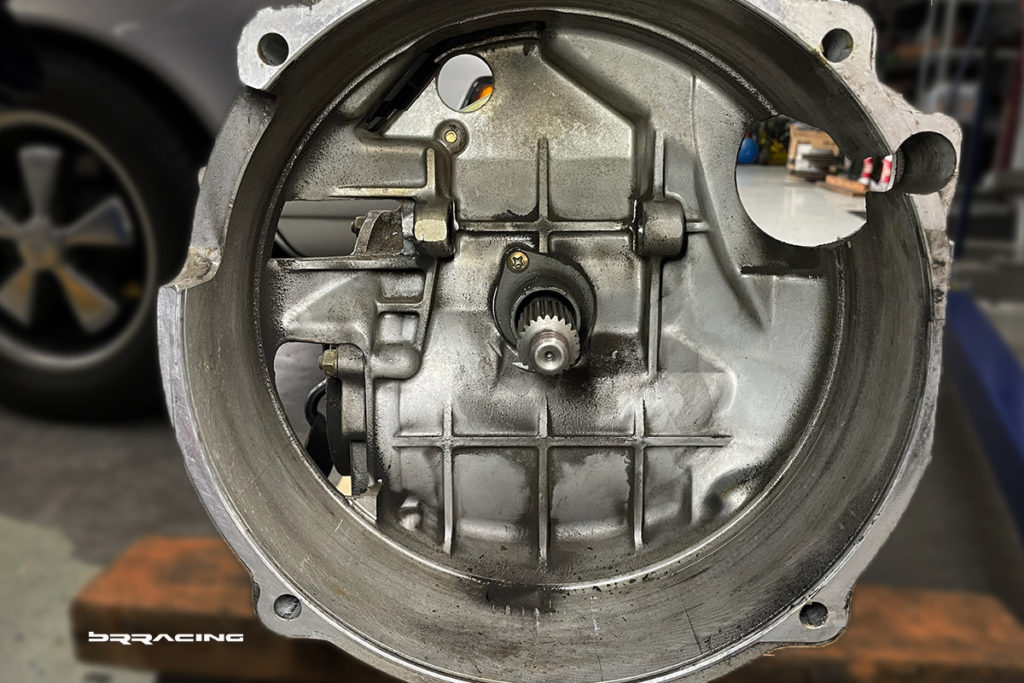

Transmission got fully cleaned and prepped, and ready to re-install to the engine.

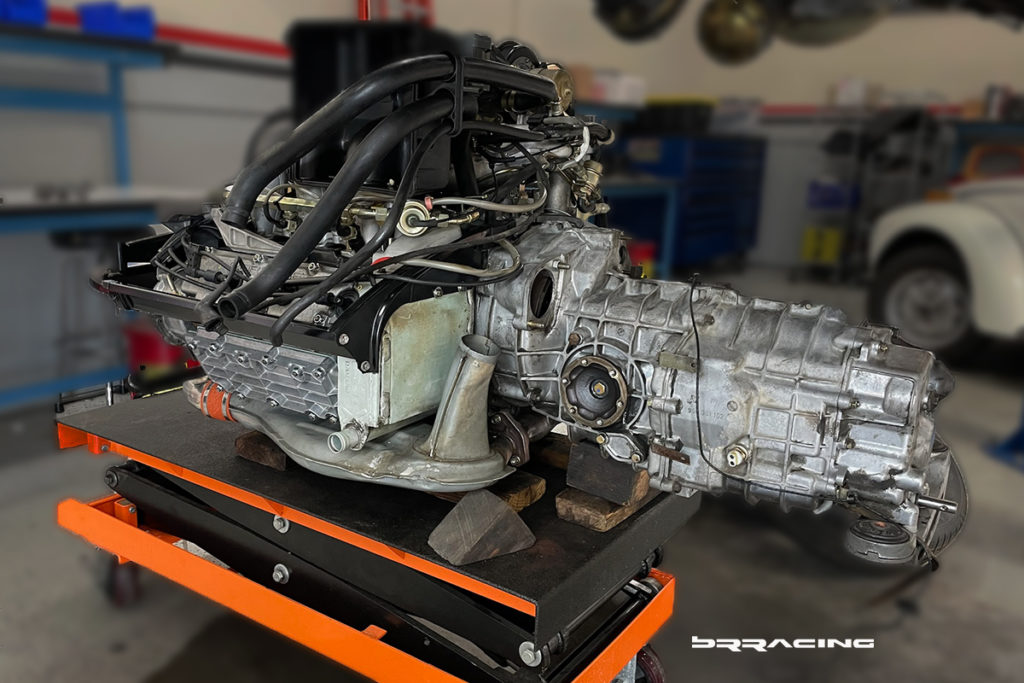

Attached the transmission to the engine, and the complete assembly ready for installation back into the car.

Now, before we go to install the rebuilt engine and transmission, we have to attend to the rest of the car, mainly the suspension in this case. As seen before, many parts needed attention, many suspension bushings were soft, cracked, torn, and needing replacement. Shocks were soft, mounts were bad, so all of that now needed to be refreshed, and only replaced if necessary, and mainly the bushings, bearings.

Here is the rear swing plate / torsion bar. Bushings and bearing surfaces bad.

In this case, easier / less expensive to just replace the complete swing plate with a newer generation.

Brakes were examined…the rotors just needed cleaning, the pads were good, and the calipers were cleaned and rebuilt with new seals. That addressed the whole underside, and now the finishing touches could be addressed, connected, fuel system rebuilt, and all assembled back into the car.

Almost complete….the great news was the pristine interior, front trunk area. Just minor cleaning, and ready for completion.

As mentioned earlier, the wheels needed attention, and the tires were way past their time…so, refinished the wheels in a matching color to the car, and new tires mounted and balanced.

Finally, an alignment and test drive…and the car was ready to go. Total time from start to finish was only 8 weeks!

How can you best this…a fully freshened 1988 911 with only 28k miles!

What can BRracing rescue for you?