BRR Porsche 997.2 GT3

Updated August 2012 (yep, we’ve been making enhancements to this car for nearly 3 years now, and still going….but there’s a reason its nearly the fastest street car on the track as demonstrated by our many Porsche Owners Club and PCA Time Trial wins).? See the end of this write up for a full listing of all the parts and upgrades.

Introduction of the build of the BRracing 2010 GT3. Not that the 2010 GT3 is a normal daily driver to begin with (it truly is an amazing car, and a great set of improvements over the previous generation 997 GT3), but with the new improvements that have been made to the car, we saw this as a great canvas to highlight some of the recent solutions and new products available to make this a truly amazing car. Just like the other BRracing project cars where we can’t leave a great car just as a normal car….this project will have quite a life, and we will detail the improvement here, why we choose the products we did, and the results, both on the street and the track (and just like our other projects, we’re happy to prove the results on the track with anyone…our car will be at the track at least once a month for testing and development….and it’s first appointment at the track will be in 2 weeks, after we’re back from SEMA 2009).

Here is the base canvas that we started with –

Porsche 2010 3.8 GT3

Sport Carbon Fiber seats

Technology package

Blue tooth

Nav

Dynamic drive lights

Alcantara package

Sport Chrono

Full leather package

Porsche Carbon Fiber Ceramic Braking system

Pirelli Corsa tires

But, that’s just the beginning.

Here are some pics of the base canvas.

If you know about this new Porsche, then you can pick out the one really significant new addition to this Porsche, unlike any other Porsche from the factory. ?Its the “center lock” wheels. ?No more lug bolts…just one massive center lock hub nut, just like on the racing cars. ? This really cleans up the look of the wheels, but you better be ready to spend a pretty dollar to get a new special, loooooooooong torque wrench, as you have to exert more than 500NM of force to get the wheels tightened. ?And…do NOT attach this w your impact gun….NO, NO, NO. ?You also have to have a special socket that unlocks the center lock nut while applying the torque wrench.

Such a great car already….but, like a canvas, it’s crying out to have some changes made…so, off come the brakes…even though brand new, they have proven not to be the BEST solution for track use.

Vehicle has been lowered to euro ride height.

November 3, 2009 updates to the car.

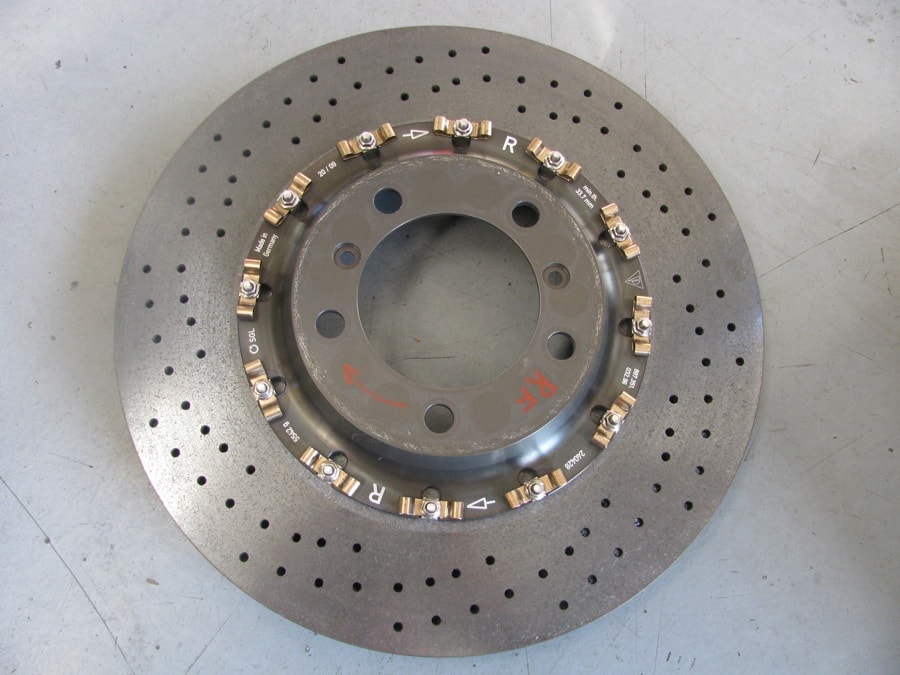

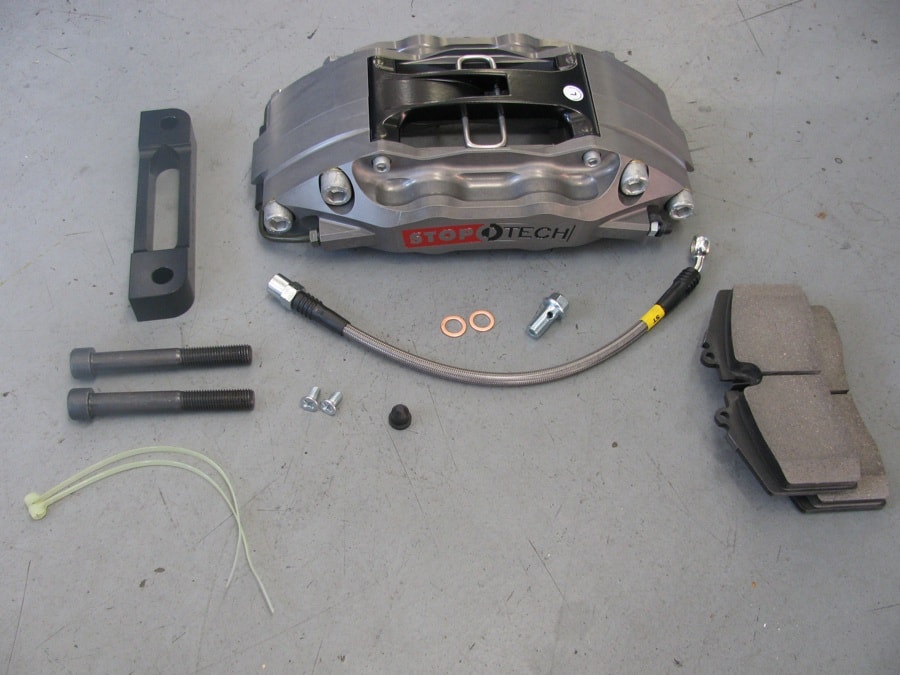

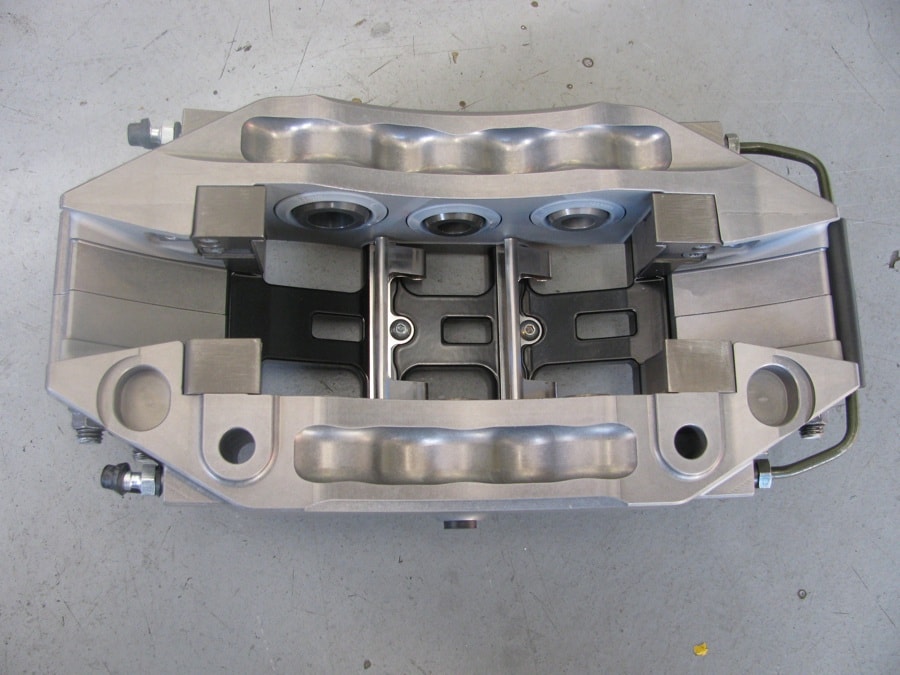

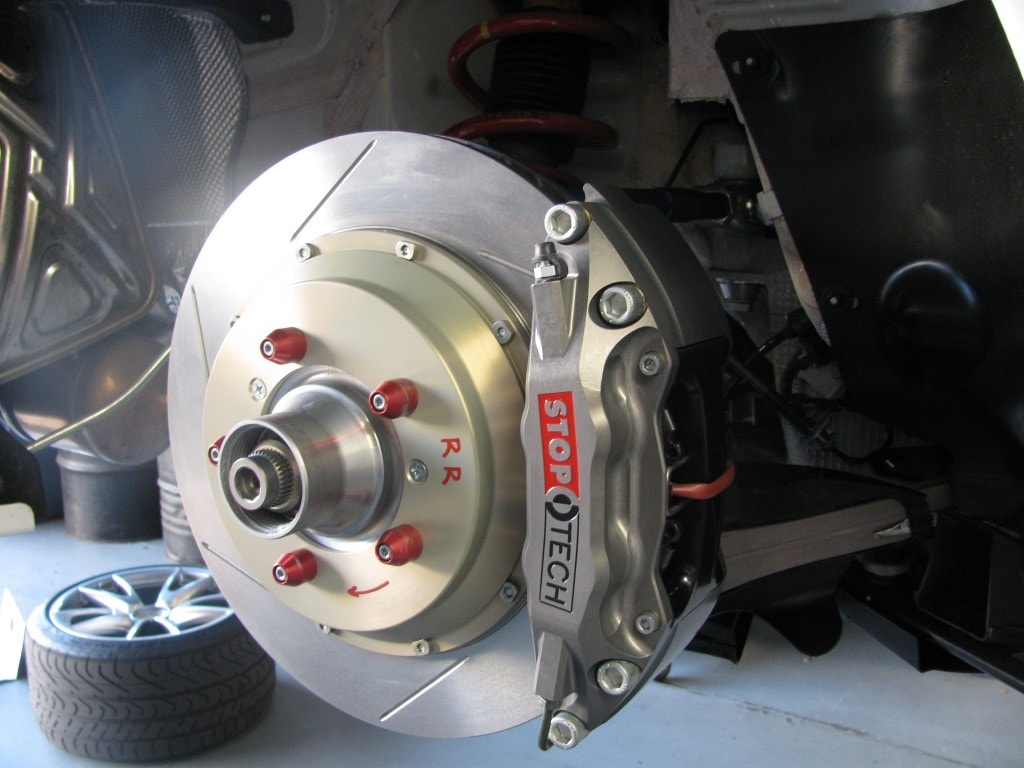

As stated above, off come the brakes. ?Porsche has continued to invest in the development of the ceramics (Porsche carbon ceramics brakes, or PCCB). ?The issue w the PCCB has been both that they don’t have the bite that we desire for aggressive driving or track days, and that there are NO options for pad choices. ?So, we want this car to be the best project solution possible, so off come the PCCB brake system, and on go ?a new system that has just been developed specifically for the new 997.2 GT3. ?The new system is the STR60 system from Stoptech. ?We spent a great deal of time w Stoptech at the recent American Le Mans races, and probed and questioned what the differences were in their systems vs all other leading solutions on the market (and if you don’t know Stoptech, you can take comfort in knowing that they were on the winning Porsche at the Speed GT race at Laguna, on many other cars in the field, and also on many of the leading Touring cars (like BMWs) in the races that weekend. ?They have quickly developed a leading position in the braking market due to their precise design and fitment of the complete braking solution for each car…..most others adapt the same braking system for use on many different cars, but this is not the case w Stoptech, they design each caliper and rotor combination to match the specific braking requirements for that application).

The Stoptech 2 piece brake rotor weighs slightly more than the PCCB rotors they replace, but the calipers are slightly lighter than the PCCB calipers that were on the car. ?However, the performance and pad selection benefits far outweigh the downside of slightly more weight in the total system. ?We have also just recently completed some testing on brake pad options for Porsches, and believe that the best pad combination for track use and some dd use are the Performance Friction pads (97 and 01 pad compounds….and we are running different pad compounds on the front vs the rear to help settle the car down under aggressive or very hard braking).

Ping us if you have any questions about this new setup, as we are the FIRST 997.2 GT3 car to have this key new system. ?Notice that the calipers do NOT have any paint, as the temperatures that the caliper will reach will toast any paint job on the calipers (and just look at our OEM BMW 135i brake calipers if you want proof of that…the Brembo’s look like they went thru a fire…..the white lettering on the side is now a dark yellow color….yech). ? This again is the same as the true race systems you see at the track….we’re going HARD core here.

Here are some pics of the original PCCB system on the car….

Here is a quick pic of the comparison of the new Stoptech steel rotor to the original PCCB rotor –

Here are the other elements of the Stoptech system, and the mounting on the car….

Don’t those things look amazing….filling the whole wheel area w massive braking power.

So, now we have the car, we have the brakes to stop the car…..so, on to the next step in the development. ?Stay tuned…..

Update – November 6, 2009

Next set of updates to the project car, in preparation for the November track day testing we have planned.

As we have said….we’re moving fast on this project, no small steps being taken, but big steps, and very deliberate steps…each piece, each element is being reviewed and selected to achieve optimum results. We’re not just trying to put together a new 997.2 GT3 for track use, we’re trying to make a killing machine that can tame any course, any time.

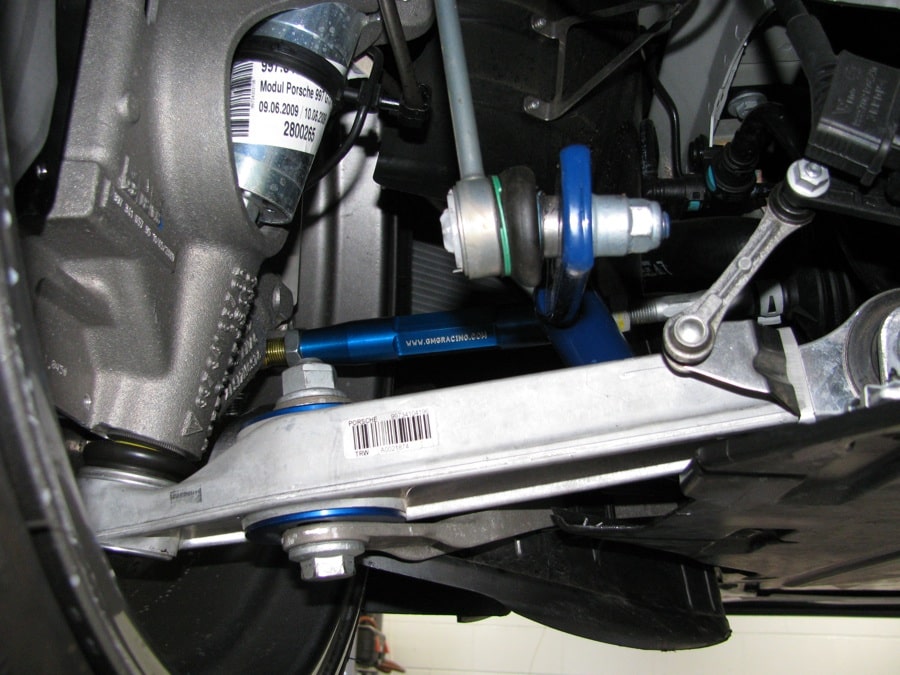

So, as we knew from the testing we have done w our customers 996 GT3, 997 GT3, 996 TT and 997 TT, the suspension has too much play and movement when you bring the car to the track….in fact, it can be a near frightening experience when you really get on the brakes hard, like going into braking for Turn 2 at Laguna, and you can feel the car wiggle from side to side….and you’re just holding your breadth hoping that the car will stay going in the right direction….but…

So, when we have installed replacement bushings, links, toe links….the car has settled right down, and become much more stable, but also much more refined in responding to inputs, not just under braking, but all thru the turns.

So, the 2010 GT3 needs this same level of refinement, so, off w the OEM, and on w the new, and only the best will do for sure….

(You can also see the new Ferrari 599 we were installing a Novitec suspension on this past week)

Here are the new suspension toe links…the half set for the front, the full set for the rear. ?As testing in the Porsche race car has shown, the suspension travel and changes while under load can induce some significant understeer, so off the OEM ones go, and on the full monoball units w no rubber for any deflection under load

Here (below) you can see the toe links, the new rear sway bar, the rear “dog bones (set of 4)”, and the rear full toe links

This is the same shot on the left rear side

The thrust arm bushings on the front suspension arms

The front half toe links, front sway bar, and front thrust arm bushings

That completes the SUSPENSION upgrades for now…more to come later, but we still have more to do to get the car ready for the track

Next update – November ?9, 2009

Yep…the weekend is approaching for the first track test…so, time to get some more mods done…we’ve got a list that we have to complete before we make it out on the track, as we want to get a base platform to evaluate the future mods against….

As was recently stated in another post in the forums….safety is REALLY important, and we know that the GMG harness bar / roll bar has the build quality and strength…so, in goes the new GMG designed roll bar / harness bar / rear shock tower brace for the 2010 GT3 (which you can get from us, and also the installation if needed). The new design has a different fastener approach, even furthering the strength and rigidity of the solution. We are also installing Willans harness 6-point sets for both seats (we have the new Porsche CF seats on both sides).

Since we’re going to the track this next week, this is a necessary step in the build process….

In the first pic you can see the exceptional quality of the existing CF seats….truly pretty, light, and awesome.

The new GMG roll bar and harness bar have the new hardware to improve the torsional rigidity of the system, and have the nicely ?integrated touches of the harness bolt receivers (the hooks that you can screw into the harness bar so that you can “click in” the harnesses.

Update – November 11, 2009

And the next natural step…..we need some sweet music to listen to while driving…

You may have heard one of the guests / visitors here who stopped by the shop this past weekend to see the progress on the car and talk about the nice sound…..and as someone said today, this sound is a “Man” sound….there is nothing secret about its intentions. But, the fun is that you can sit and play w the valving and change the sound note from aggressive (loud, but not out of control), to MEAN (we wanted it to sound just like a Cup car at the track….we LOVE the sound of the Cup car…and we think we have it, but Saturday November 14, 2009 will be the true test).

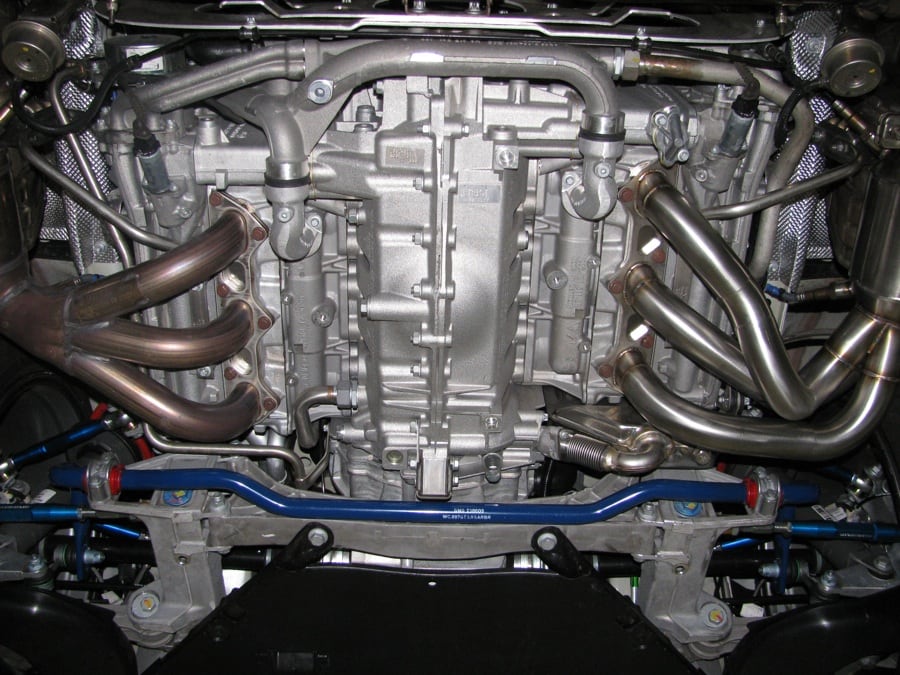

Here are some pics of the 2010 997.2 GT3 OEM headers, cats and exhaust.

Notice the significant bend in the OEM exhausts as they enter the cats….more on that later…

here is a comparison view of the OEM headers on the left side, and the new GMG sport headers and high flow 200 cell cats on the right

close up view of the cats and muffler up in the rear fender well area

Here is the close up of the OEM headers and cats, where you can see the strong bend in the piping entering the OEM cats

A complete view of the new GMG sport headers and cats, and you can notice the smooth flow of the exhaust tubing into the cats

Not only did we do the headers and cats, but also the replacement of the rear center section w a new GMG unit….and we love the way the center section expands the tubing from the exit of the mufflers to grow in size and then turn and exit the car w beautiful tips…nice clean flow the whole way, and we love the look from outside the car as well

Nicely completed….major sound resides inside ?:)

Still more to come…

Update, November 13, 2009…final update before the track day

The next problem that demanded an answer was intake flow, and rear downforce…..answer is a new rear decklid and rear wing.

We took the current 2010 997.2 GT3 rear deck lid, the inside portion, and mated it to a 2009 997.1 GT3 Cup Car top deck lid, Cup Car uprights, and then a Cup Car rear wing. To this, we then added new CF air scoops on top, and had them fully molded in to the top cover. The new scoops increase airflow by 30%, and these are currently available items (but not a straight bolt on piece for the 997.2……yet).

The result is the package we’ve been working towards…..we had the guests guessing at TH as to what this car was…but the current wing on the car is the giveaway…as the new 2010 Cup Car has a much bigger wing than this.

The first pic is the new decklid, fully molded scoops into the top (which are CF, and we left a portion of the scoops exposed so that you can see the CF element).

Here is the pic of the complete install of the new rear deck lid and Cup Car wing (plus BRR custom graphics for any car that we build like this)

You’re never done with the performance and enhancement modifications….there is always more, and more to try so that we can evaluate the benefit of different pieces, vendors, solutions, approaches.

And, so it is with the next mod. ? We loved the whole approach that we had with the rear wing and uprights…..but it was not consistent w the latest offerings from Porsche. ?They had come out with the 2010 Cup Car, and it had a new rear wing and new uprights. ? We already had the new front splitter, but now needed to add to the rear, as the new wing was wider and more efficient….meaning we could get the same amount of downforce but with less drag. ? Since the new rear uprights are not only the same from the new Carrera Cup Car, but also the same used on the full race RSR version, we decided to go the whole way, and move to the new uprights and the RSR wing blade.

The new 2010 Cup Car not only replaced the rear uprights, but also made a significant change to the rear decklid as well. ?So, our “old” carbon fiber deck lid, which we had previously had fabricated to mate the upper Cup Car section (997.1 version) to the 2010 rear inner section, would now no longer work. ?So, back to the design stage, and we took the new 2010 Carrera Cup Car upper deck lid section, which features a neat “duck bill” lift portion at the trailing edge of the center section, to further improve downforce and reduce drag, and a new intake inlet section. ?On our old intake upper section, there was two inlets….the new deck lid features a massive, single section. ?To take advantage of this new massive intake section, we also decided to update the intake, filters, and intake plenum to the current Cup Car section (we need more pow’r Capt’n). ?This completes a whole upgrade to all elements (top inlet section, top deck lid, lower deck lid to mate to the new dual filter intake system, ?and then the new, larger intake system that leads to the MAF (mass air flow sensor).

The RSR version of the rear wing blade has the center section “lifted”….to both reduce drag and get them a little higher and into the main air flow over the top of the car.

Full adjustment…and its amazing how just a single adjustment can really alter the car. ?At Laguna, we have added downforce, at Thunderhill, we have taken out downforce.

Views of the massive single inlet duct and the rear “duckbill” portion of the trailing edge of the upper decklid.

Here you can see the difference in the lower section, of the two outlets versus the single outlet we had before.

This is the new intake system, with the dual filter inlets to mate to the new upper section outputs from the new massive single inlet duct.

Next up…after the GTGP, we could really sense that we were at the limits of the current suspension. ?The car handles great, but it will bottom out in some sections at Laguna, and you can feel that it is struggling during hard cornering. ?So, we worked again w AST to implement the FIRST set of AST 5300 triple adjustable struts/shocks for the new 997.2 GT3. ?We also got these w the new “quick disconnect” hoses to the remote resv to make installation and alterations of setup easier going forward. ? The major benefits of the AST system are the range of adjustment, technology, quality, and price. ?You can see more details on our other www entries about the AST suspension system, or also check out the BMW E82 135i project car write-up on all the details there. ?We have loved the system on our BMW E82 135i, as it has allowed us to go from street setup to track setup in a heartbeat……just a few clicks and we can dial in what ever setting we need. ?Or, if we find that we are not getting the range of adjustment we desire, we can alter the nitrogen pressure in the resv themselves, and have a completely new range of adjustment to play with.

The AST system uses the “inverted” piston design on the front struts, to provide greater strength (just like Penske racing shocks, that cost TONS), and reduce friction at the radial bearing point at the top of the shock body. ? We also implemented front camber plates, and solid rear upper shock mounts.

The triple adjustable struts/shocks. ? Note the “quick disconnects” on each hose to allow removal of the strut, since, as an example, on the rear, the rear hose and unit run up and into the rear passenger area inside the car…so, don’t want to remove those every time we make a suspension change or spring rate change. ? ?You can also see the massive front piston size and the long hose needed so that we can locate the resv in the bottom of the front trunk area for ease of access and mounting.

AST front adjustable camber plate, full monoball mount.

Rear upper shock mount….solid, extra reinforcement, and monoball center.

Front strut installed….the hose exits the top of the main piston, to allow mounting of the remote resv in the front trunk area.

(if anyone wonders what is wrong w the pic above….this has indded been fixed.? It is critical to ensure, even under full droop, that the suspension stays under load.? We added a set of Swift helper springs to resolve this issue).

Rear strut/shock installed.

Here you can see the rear hose where it passes thru the body shell, and into the rear passenger area. ?We mounted the remote resv on the rear roll bar assembly, yet still easy to access for adjustment. ?We wanted the hose to be as close to the center of the car as possible, yet still a little away from the spring itself so that it would never get caught in the suspension travel.

While not a complete racing suspension, we are nearly there. We have solid bushings for most of the control arms (that’s why I say were not there yet…we still have a couple of bushings that are not full solid monoball mounts yet). We went with spring rates that are just slightly stiffer than the current Porsche Cup Cars run, given that our car is heavier than the full race car.

The suspension made a HUGE difference. We tried the suspension at both Laguna Seca and at Thunderhill Raceway. Amazing addition of grip and stability. We thought we had a relatively well dialed in car before, but now….WOW. Just like the other steps we have taken….this one was another incremental improvement, but really settles the car and inspires even more confidence.

Other items –

We are nearing the end of the front brake rotors at this point. It’s not that they have worn down, but the heat stress cracks are starting to grow and reach the outer edge of the rotor themselves. Plus, we can see some “hot” spots on the rotors themselves, after soooooo many heat cycles.? They have held up amazingly well, but now need to be replaced with new units.

When BAD things happen to GOOD CARS…..

Sometimes there is more to do, and sometimes things happen, which creates more things to do. We had just such a case. We’re not sure if this was a “cause” or a “result”, but nonetheless, it created havoc. Here is the scenario. Car has been running great, flawless. We always run diagnostics, test the car, check all items…and all had seemed just great. But, one track day in September, 2010, at Laguna Seca, coming out of turn 11 and heading up the front straight, everything seemed fine, in 2nd gear, accelerating hard, shift into 3rd gear, but it doesn’t really go into 3rd gear fully, out with the clutch, and hard on the accelerator again, and then, the car slips out of gear (3rd) and into neutral….as a result, with us hard on acceleration, we get an immediate over-rev situation, for a fraction of a second, and not a bad over-rev, but it was an over-rev (we can see it pop out of gear in the in-car video, and hear the over-rev)….so, we go to put it back into 3rd gear…we rev the motor a little, and then as we are about to engage 3rd gear…the whole car dies….dead….nothing. No motor….car just rolling up the front straight (still doing nearly 100mph when this all happens)…..we switch off the ignition while rolling, switch it on again, turn the motor over, try to start it….nothing, absolutely nothing. Finally the car rolls to a dead stop between turns 2 and 3. We continue to try to start the car, and nothing. We try lots of times. Nothing. No lights on the dash, no CEL, no visible signs of anything being wrong. The motor will turn over, and no unusual sounds from there either. The car gets towed back to the pits. We run a litany of tests, diagnostics, check all visible signs….nothing. The motor turns over, and feels like it wants to run, but won’t. No codes, no lights…..we’re stumped. We take the car home, to the shop. Run another litany of tests….do compression on all cylinders (first thought is that the cam or timing got hosed)….compression is good. Run a “leak down” test on all cylinders…..all good, spot on. Test spark to each cylinder….all good. Next…it must be a broken fuel pump. The new fuel pump, since this is a “direct injection” motor is MUCH different from the older port injected motors. The amount of fuel pressure is intense, its well over 1200psi….versus the old ones at about 70 psi. So, we get a new fuel pump, install it, test again. Nothing, no change. With no codes, no lights, no other symptoms, we’re scratching our head as to what the issue can be. Common logic would again point the finger at the timing and cams….but not an easy thing to check….the motor needs to come out.

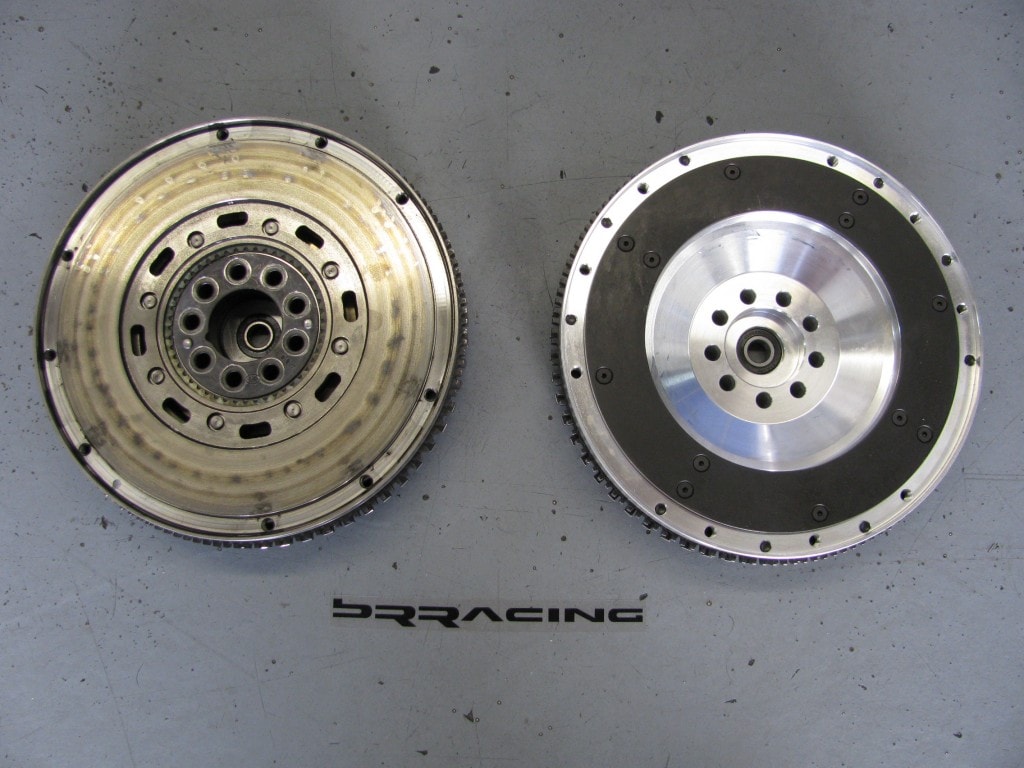

Pull the motor, tear down the engine. All looks to be fine. Everything is together, no broken parts, no visible signs. Check the cams, check the timing. Even the cam timing bolts which are know to back out are all fine.All spot on. No slippage, no change. Finally, the clutch and flywheel are taken off as well. We talk w Porsche….given the info we have, they believe that it could be the flywheel. The “tone” ring is used to set timing for the motor, and if this is off…..then, obviously the motor won’t run. But, how do you know if the flywheel is correct or not? It’s all together, looks fine, no teeth missing. So, more discussions with Porsche, and they finally find the actual specs for the alignment of the tone ring on the outside of the flywheel. Hmmmm…….based on what they’re telling us, this couldn’t be it, as the tone ring is not just a little off from where they think it should be…..its’ WAY OFF…its moved almost nearly a quarter way around the flywheel, and yet is still looking like brand new. The section where there are no teeth (the signal section) should be where the words “good” are located. WOW….yet, visual inspection it all looks fine. No signs on the flywheel, no marks, no centering locations….how would you ever know?

So, off with the old, and on with the new. BUT…like we have learned in all our years of racing, if the car is going to be subjected to the trials and tribulations of racing, and we have an issue, we don’t just go back on with a new part that could fail again, we find a better solution. So, the hunt begins for the BEST flywheel that is out there for a street car that sees track duty. And, we want one that addresses the core or root issue here….the security of the tone ring on the flywheel itself.

Next, remember what we think gave cause to this whole issue……why did the tone ring spin? Was it due to hard acceleration? Was it due to the over-rev? Most would shake their head to the over-rev condition…so, what caused the engine to over-rev? The missed shift….why did it miss shift? Why has it been getting harder and harder to make the shift from 2nd to 3rd? Was this driver error? Well, it wasn’t driver error…as we have had three of us drive the car, and ALL of us reported the exact same conditions, under the same scenarios. Under real hard, full throttle acceleration, the shift from 2nd to 3rd is almost impossible to complete. You can never do this without thinking, you have to be very deliberate….very intentional. So, is there another root cause to this whole episode? The new 2010 GT3 has the special, new, hydraulic motor mounts, that are supposed to stiffen under hard acceleration. Is the motor twisting, and causing the transmission to twist as well under hard acceleration that is binding the shift linkage? Is there a difference between the 997.1 GT3, that didn’t have the new motor mounts, and the version we have? Has the shift linkage changed? Well….this is exactly why we do what we do. We test, we learn, we probe….and we find answers. So, there is an issue, and stay tuned, as we will detail what we found to really be the root cause of this whole BAD experience. But, back to the flywheel….and enter our friends from AASCO, the leader in flywheel solutions for Porsche. They have just what we need….a lightweight (we love performance gains), secure flywheel with a BOLTED tone ring. Direct replacement, and will work with our current clutch/pressure plate. Here is a set of pics of the new unit –

Besides getting a better flywheel…..we also get the weight savings…..the stock one weighed in at 30lbs, almost spot on.

The new one weighs in at 15lbs, almost exactly half the weight. ?Woo Hoo….

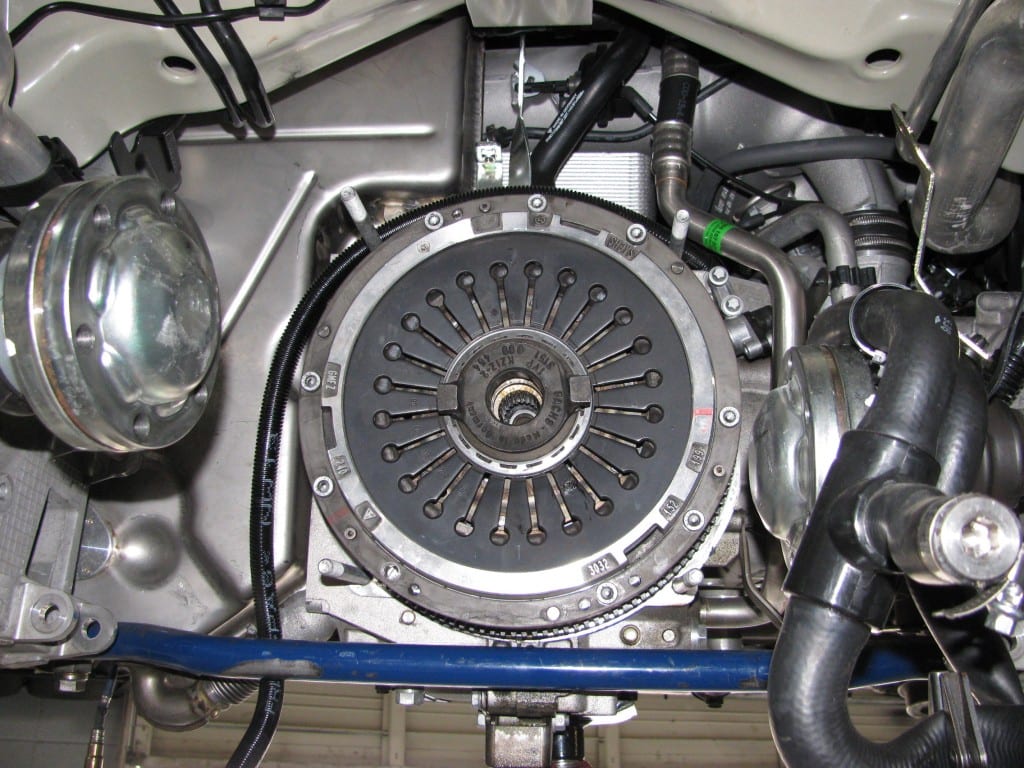

The new flywheel, stock clutch and pressure plate back in the car and ready to be assembled again.? (anyone care to wonder why we didn’t install the GT3-RS lightweight flywheel, pressure plate and clutch? All we can is DON’T do it…don’t do it.? We will explain in other articles, but those units will not hold together for track use).

Putting the tranny back in the car (headers are off the car as well….more on that (remember what we said above about timing and fuel….hmmm)

So, the tranny and motor are back together….and on to the next issue.

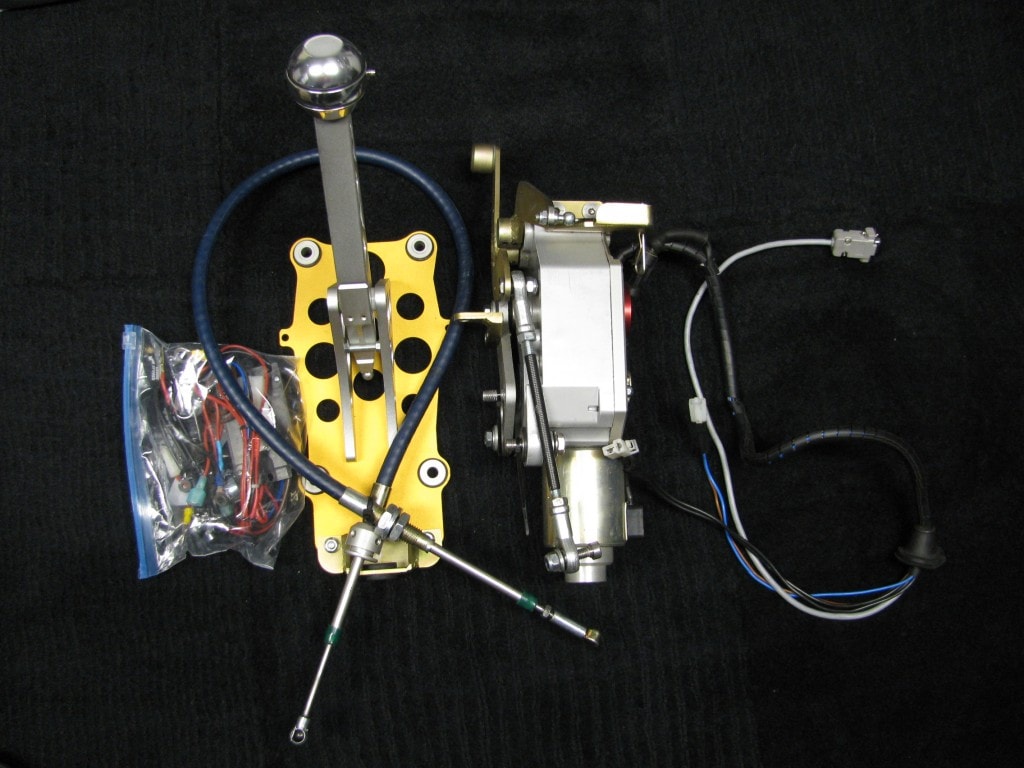

What caused this whole episode…..not the flywheel….it was the innocent victim. Not the motor mounts, for after a ton of research and discussions, we found that pre- 2010 GT3 owners are having the same problem….its the shift linkage. That DID change, and the bushings in the stock GT3 shift linkage are too soft…and prevent the shift from 2nd to 3rd. So, next up….replacing the shift linkage, and as we said before, if something doesn’t work, we want to replace it with something better.

SHIFT happens

We found that the new GT3 shift cables, in all elements, are soft and weak. The cable ends are the main issue though. Plastic, soft bushings, and when put under load or stress, they flex too much, and therefore do not transmit the proper effort to the transmission to make the complete exchange and movement of gears….there are two shift cables, one which controls fore and aft movement location, and the other which controls/transmits side to side movement and location. The combination of the two then determine the exact location to the transmission for each gear location and engagement. If these are off, then the transmission will not be in the proper location for that gear…..and havoc will result, or a very difficult or impossible gear exchange and engagement. Under no load, the shift mechanism works just fine, but under load, the cables and bushings flex too much. After research and discussion, the solution we found (and others have as well), is the installation of the factory 996 Cup Car shift cables (the later versions of the Cup Car went to a different transmission (sequential), so those cables won’t work), but this set will. Made by the factory, for this transmission, and all upgraded parts…..PERFECT.

Here is a look at the two types of ends on the cables that attach to the shifter….the factory one is the plastic unit on the left, the 996 Cup Car unit is the all metal on the right.

Here is the other end, where they connect to the transmission. ? This is the 996 Cup version installed. All solid, no plastic. Even the cables themselves are meant for work, as the inner cable is about 33% thicker than the OEM stock versions. There was a reason they made the Cup Car items this way….and now we all know why.

Installation of the new shift cables in our GT3 (if you consider this, be prepared….you have to take nearly the complete center console and all related parts completely out of the car, including where they intersect the center dash console area). Once you have EVERYTHING out, it’s not too bad….we did this at the track, as we were under a crunch in time (we did this just before the GTGP, as we just got the new clutch and flywheel in the car, but didn’t want to cause the same issue again on the track, so, with Porsche Motorsports there at the track, we could get all the parts, and started flailing at the car, and worked till we had the car ready to go)….the parts are a standard part number from Porsche Motorsports, but you can only get them as Porsche Motorsports parts.

The result….a great new shifter, and the shifts are precise, accurate, and trouble free.

So, now we have the car in great condition, and working the way it should….with a new flywheel and a new shift cable solution.

KA-Blooey…..sort of

Remember….if you’ve read this far…..wow….anyway, if you read above about the flywheel, and the motor turning itself off….well, it finally shut down the motor, due to the timing being so far off. But, what did that mean about fuel being poured into the motor and not getting burnt right?? Think about that….what happens on street cars today when you get a misfire in a cylinder, and the motor hasn’t yet turned off the injector for that cylinder? Hmm….that unburnt gas has to go somewhere….somewhere……

And, when it does, and works its magic somewhere else, something like this starts to happen….

This is the other side of the picture above…..and what’s left of the 200 cell SPORT CATS in the headers. If you don’t know what this should look like, it shouldn’t look like this….it should be completely filled, and look like a beehive inside the cat area…..but, not after you feed it too much fuel, and let it go KA-Blooey.

And, this didn’t happen to just one side….it happened to BOTH sides.

So, just like with the flywheel, and then the shift cables…and now the CATS. When something fails, we need to replace it with something better.? The choices were as follows (1) put back the stock headers, stock cats, and lose power, (2) put back in a new set of 200 cell sport cats and headers, and hope that it doesn’t happen again, (3) put in a set of RACE cats (from Porsche)(100 cell), but then the engine will throw codes, and the engine will need a custom tune, as the A/F and O2 readings will not be what the DME thinks it should be, and crazy things will happen, or (4) go hard core, and run straight race headers and a custom tune.

What option did you pick?

Well…..we pick option #4. Going backwards to stock didn’t make sense, and it could all happen again, plus we would have less power and sound waiting for it to go KA-Blooey again. We could do #2, as that worked fine….but, we don’t know if we are sitting on a time bomb, and it will go KA-Blooey again anyway. If we went to #3…..why only go half way. If we need a new set of headers, and we need a custom tune, why not make them (headers) really do what the Cup cars do, and why not get the most from the custom tune. So, we’re going HARD CORE. And, this actually gives us a 2 option solution. We will keep our stock DME, and our stock headers and cats, and we will install a full race set of headers that mate to the rest of the exhaust system, and we will get a custom DME (with a custom tune), so that we can run without CATS, optimize the performance, and ensure we don’t have the ingredients to go KA-Blooey any more.

Stay tuned for that next step.

Front flares, splitter, and bigger front wheels

Now that we have had some time with the car, we are starting to dial it in. We continue to adhere to the mantra, “this is a street car that can be driven on the track”, not a track car that can be driven on the street. This is key in all the decisions that get made relative to the enhancements for the car. We haven’t taken any steps to remove any creature comforts…..still has the full interior, both seats, all street seatbelts, AC, full stereo, full dash, all body panels…nothing has come out of the car, only new parts have gone in to replace OEM parts. However, we don’t limit ourselves to the standard aftermarket parts solutions….we will look or make what we need to truly make the car shine.

You might notice that we did quite a bit of upgrades to the “aero” on the rear end of the car, but what about the front end? The rear has been planted at all the tracks we have gone to, but we are not getting the car to rotate into the turns on entry, and this is lowering our turn entry speeds. We could have just added some home-made splitter element to the existing GT3 front end, but this wouldn’t allow us to leverage the full benefit of the rear wing treatment….we needed a balanced front end. So, off w the front bumper cover, on w a new cover, and to mate to it, we added the GMG World Challenge front end adjustable splitter w brake channels. Not only does this splitter extend farther forward and have an adjustable splitter length, but the bottom side allows for complete sealing of the underbody and adds brake duct channels to enhance brake cooling flow. However, this unit is made to mate to the WC wide body or Cup Car front end….which means we needed to change the front fenders on the car as well….oh well….so, be it….we need to go WIDE on the front end then. Just like in remodeling a house, a decision about the kitchen upgrades affects the bathrooms which affects the bedrooms which affects the garage which…. We loved the idea of going wide in the front….that, along w the new front splitter, would also allow us to gain in the total track width of the front axle and increase the tire width size and overall front end grip…..but, if we were going to add THAT MUCH grip, then we would have to upgrade the rear as well. Oh well….lets go BIG there too. So, we added the molded Cup Car front fenders (these are slightly bigger than the wide body GT3-RS versions) the front fender extensions to mate to the new front bumper cover, and obviously, the new Carbon Fiber adjustable front splitter.

So, what to do about the wider front track? GO WIDE as the saying goes. We had our friends at GMG make us a set of new, custom, front World Challenge GT wheels in 19″ x 10″ size (we loved the look of the prior set we had, they took all the track abuse we could dish out, they are as light as heck, and we never had any issue w the center lock area or wheel torque), with the custom offset we needed to maximize the front wheel width, tire size, and fit the new front fender extensions. To further enhance the usefullness of these new wheels, we had them ceramic coated…..we deal w the brake dust and tire fragments from each track session, and the ceramic coating looks great and helps us keep the wheels clean.

If we went wide on the front (changing both track track width and tire size), then we couldn’t leave the rear alone. We need to keep the car and total foot print in balance. So, we added the same new wheels to the rear, going with 19″ x 12″ GMG World Challenge wheels w the same ceramic coating. This allowed us to maximize the offset and tire size in the rear (we could still fit even wider tires on the rear, but we want to keep the balance).

I’ll mention the size of the tires, but this is a little misleading. This is true with all tires…just because two tires are the same size, does NOT mean they are the same size. Tires in the same size (same width, same aspect ratio, same diameter), can be off by as much as 1/4″ to 1/2″. So, we are now running 265/35/19 on the front, and 315/35/19 on the rear (remember this is still a narrow body rear end car, not a GT3-RS wide body car) This is a significant step up in total tire patch for us on this car (but you can go bigger still).

The car now has tremendous amounts of grip…..for some of us, limits that are beyond our normal physical and mental sense of where we think the limits are (this surely must be the limit, then you push and test the car, and it just gobbles up the pavement w nearly a heartbeat missed. How good is the car??? Good enough that at the POC event at Willow Springs in Dec 2011, we entered the car in the Time Trial, and recorded a time of 1:29.3 (good for 1st place by a large margin), and this was with Bruce driving (not Robb, who would have been faster, and likely into the 1:28′s….I know the car has it in it). The car is simply amazing, and many at Willow Springs came by to see the car, and thought it was a Cup Car, not a street legal GT3. We believe!

But….there is more coming in 2012….stay tuned.

And, at this point, if you want to know the specifics of what we have on the car, here is the list as best as we can recall –

StopTech STR60 front brakes, 380x32mm rotors

StopTech STR40 rear brakes, 355x32mm rotors

Thrust arm bushings, front and rear – GMG

Dog bone rear upper control arms – GMG

Toe link kit, half, front – GMG

Toe link kit, full, rear – GMG

Front and rear sway bar set – GMG WC GT3

Sway bar end links, front and rear – Tarett Engineering

Wire mesh to front grill openings and fender well openings

Chase cam system (PDR 100) (DM10 data module), camera, mount

Sparco 375 steering wheel

Steering wheel quick release – Sparco

Racing Radio

May 2012 – The next enhancement had nothing to do with performance….not directly at least. Living in CA, we have the luxury of running at many tracks at good times of the year and good weather, but as we expand our track program and locations we run at, we are finding that we are running when its hot out….real warm. So, the next enhancement was for the driver…and by keeping the driver cool, we could get more track time and better long term performance, or better performance at the end of the day when Time Trials are run. So, in with a COOL SUIT system. There are only a couple of systems out there to choose from. Since this was going in a street car, there were some additional considerations. We could not put this on the floor in the passenger area like we do with our race cars. We can’t put in the back seat area either. So, we decide to put it in the front trunk area, but this has space limitations. Therefore, the system we picked was the FAST and CoolShirt system. CoolShirt also just came out with a new shirt that is much like the 986 system design, and works great. We liked the price as well., and we like the seal on the box to keep all the fluid inside and not sloshing around.

As you will have read above, we had the issue once w an over-rev caused by the manual shift cables, and we had changed to the Porsche Motorsport 996 Cup Car cables.? But, that still was not enough.? So, the next upgrade was to change from the stock manual shifter to AutoQuest semi-sequential shifter system.? The transmission stays the same, but the shifter changes from an “H” pattern to a forward and back shift system, much like a Cup Car sequential.? There are some nifty features of this system, as it has features that prevent over-revs on downshifts.? It also now has an auto-blipper fixture (also a copy of the Cup Car auto-blipper system) to further assist in the downshift.? You have to do each gear just like a manual, no “bang, bang, bang” to drop three gears, you still shift each gear, but the lever just moves forward.? The time to shift is still less, but not as quick as a true sequential.? But, everyone who has driven this setup (we now have four cars w this setup), love the upgrade.? As part of the kit, you get a new shift gear display, which tells you which gear you are in at any time.

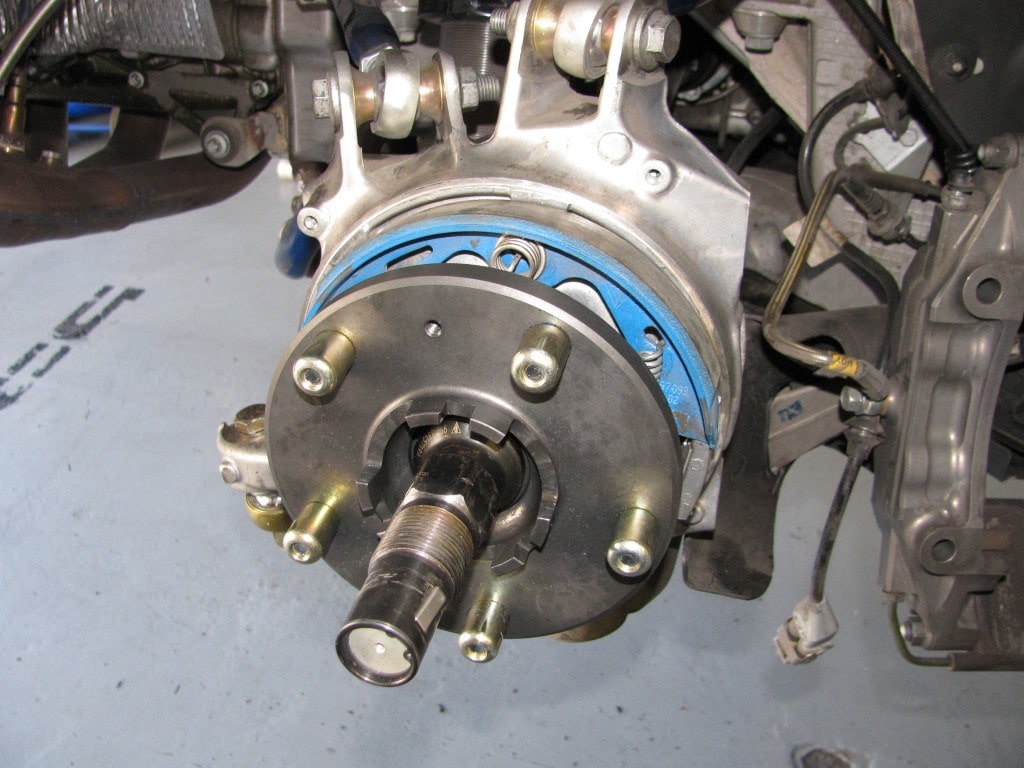

June 2012 – We’re not sure how to categorize this. But, the main reason is SAFETY. This is all about the center lock wheels on the 997.2 cars. In May 2012 we had one of our customers have a rear hub failure w the center lock wheels. There is a lot written up about this issue. We are aware of over 18 cases of center lock failures on the track to date. Most are the rear wheels, and most of those are the right rear. There are no hard facts as to why this is happening, but there is no question it is happening. And, in our case, we can attest that we have done the torqueing of the wheels in line w the Porsche published spec and procedure. We can also attest that the car that had the failure had not been abusive in its driving, it wasn’t curb hopping, hitting holes, dropping wheels off the course, shifting hard, or anything that we can think of that could contribute to the failure (and I was driving behind the car w the failure when it happened). We talked w all that we could, and no one can tell us what the reason is for the failure, how to tell if a wheel hub was prone to failure, what the signs are of a pending failure…..they can’t tell us anything, yet we know they fail. So, for our customers, how do we know when the center lock wheel hub is OK, or when it could fail again and cause a total loss of the car? Almost all the failures we know of have resulted in a near total loss of the car. We couldn’t sit on the sidelines and just cross our fingers and hope that it wouldn’t happen again. As a result, with our concern for safety, we decided that we needed to go a different direction w our wheel hubs….which meant either a 5 lug solution or a Porsche Cup Car center lock solution. We looked at both, and did a bunch of investigation into the fitment of the Cup Car center lock system. Since we were looking for the safest solution for track use, we leaned in the direction of the Porsche center lock, since they have been used for years in all the varieties of race series and have never had any failures. Robust, still offering all the benefits of center locks, known wheels that fit….

Here are some pics of the center locks hubs before replacement

The point of where the failure occurs is right where the inner threads for the center lock nut stop, and the outer surface changes shape. But, if you examine other hubs in this area, you can’t find any signs of stress, wear, torque stretching, or anything else. To follow the Porsche procedure to the T for a track day car is also a pain, as we need to check the torque after every outing, which means taking the center nut off, redoing the whole procedure (as the procedure doesn’t say how often you need to do the greasing and taking apart of the hub), just that you need to do it every time you put the center lock on. For a street car, this isn’t a big deal, but for track cars, where we have to do it 4 or 5 times a day, this is a huge pain. And, to do it fully, normally requires the use of two people, as the car has to be fully up in the air as well when you tighten the center locks, it can not be on the ground (otherwise the torque reading could be off).

Therefore…since we can not know the status of the health of the center lock hub….how can we continue to have faith that they will just be fine? We can’t see when they go bad, we can’t see any deformation, we can’t see or test the torque to know if stretch has occurred. What are we to do? Are we just to pretend that they won’t go bad again? Are we to think that it won’t happen to us (when obviously it has)? Therefore….therefore, we are compelled to make a design change. This is not a no-brainer, as it comes at considerable expense. But, the flip side is much worse.

Even the choice of moving to the center lock is not a no-brainer. The 5 lug is a known working solution, as it came as an option on the early 997.1 cars. We know that the Cup Car center lock is a known working solution as well, but on the Cup Car, not the street cars. So, we looked at all the components of a street 997 GT3 & RS vs the Cup Car to see what this would entail. We even had some desire to see if we should just move over the complete hub / upright assembly in total….but there are indeed too many different pieces and connecting points (example, the Cup Cars use a bladed sway bar, and the attachment point is completely different). We knew the hub itself would move and fit, but what we didn’t know exactly when we first investigated was the alignment of the center line of the center lock hub vs the 5 lug hub. This would affect which wheels and what tire size could be used. This turned out to be key. On the GT3, which is a narrow body car, the fitment will be tight. On an RS (wide body car), the fitment is much more straight forward, but still not exactly the same (the RS front fender flares are not the exact same as the Cup Car, the Cup Cars are about 1/4″ wider and cleaner underneath). So, the easy part is putting on the new hubs. Just take off the complete hub assembly, press out the old center lock hub flange, press out the wheel bearing, press in the new wheel bearing and Cup Car center lock hub flange, and bolt the whole assembly back in the car. Same on the rear. But, knowledge is needed to know what wheel offset and size can be used on the front. The rear is the normal offset and wheel size on a GT3 and an RS.

If you remember on this project car, we have the front Cup Car fenders, so that made our whole choice a lot easier…the fitment is exactly the same as the Cup Car. We love the BBS wheels that the Cup Car uses (and you could use the new monoblok wheels that the new 2012 Cup Cars come with, but there have been issues w that wheel as well (see notes on the web about wheel failures in Cup races)).

But, here is again where things get strange. We had our OEM street center lock failure in May 2012. We started this investigation in June 2012. We did our first project (on another customers cars) in late June, and all went well. We tested the car in early July. All went well. So, we embarked on doing the upgrade to this car as well, and ordered the same parts from Porsche Motorsport. When we got the new rear hub flanges, they were not the same as the ones we have as spares for our other Cup Cars, nor were they the same as the set we just installed. We thought Porsche Motorsport had sent us the WRONG units. We reviewed part numbers. Nope, these were the right ones. But, they were HUGELY different from the ones we had just installed, and had as spares. We asked what the deal was…..well, Porsche Motorsport had initiated a parts recall/replacement, and the old hubs were no longer available, only these new ones. Hmmm…..makes you wonder. The Cup Car hub has been around for a long time….why now, all of a sudden, does the design change. And, it is quite obvious what the design change is. The new units are MASSIVE compared to the old units. Here are some pics of the old vs the new Cup Car center lock rear hub flange –

It every way the new unit is significantly different than the old unit….and it weighs a lot more as well. Even the inner axle stub wall has been made thicker. The wheel bearing is the same, and the outer pins are the same….the only piece that changed was the hub itself. Hmmm, do we smell an issue here? Well, on with the new, and out with the old.

Here is the new rear center lock hub installed –

The upgrade cost for the Cup Car center lock is about double the cost of the traditional 5 lug approach. To do this, costs about $1400 per corner for parts. Labor is the same for either approach. There are many features that we like about the center lock approach (naturally, since this is the direction we went), but for the average track goer, the 5 lug would be a good choice. If you are a heavy track user, then we would recommend the Cup Car center lock approach.

We have now done this to a couple of cars, and have put them through multiple track events, and all has worked great. The other benefit has been the move back to 18″ wheels like the current Cup Car. This has provided a wider selection of tires, and also some tire savings. Given the rate of our customers tire consumption, this is a key value.

List of all the enhancements to date –

StopTech STR60 front brakes, 380x32mm rotors (trophy race)

StopTech STR40 rear brakes, 355x32mm rotors (trophy race)

Thrust arm bushings, front and rear – GMG

Dog bone rear upper control arms – GMG

Toe link kit, half, front w bump steer – GMG

Toe link kit, full, rear w bump steer – GMG

Front and rear sway bar set – GMG WC GT3

Sway bar end links, front and rear – Tarett Engineering

AST triple adj struts/shocks, w remote resv, Swift springs

Shock pots (4)

Engine – upgraded DME

Exhaust – GMG Ti center section

Porsche Motorsport 997.2 Cup Car intake

Wire mesh to front grill openings and fender well openings

Chase cam system (PDR 100) (DM10 data module), camera, mount

Sparco 375 steering wheel

Steering wheel quick release – Sparco

Racing Radio

FAST coolsuit system (front trunk area mount)

Brake Pads – either Endless ME20 or Endless N05U

Brake Fluid – Endless RF650

Wheel hubs – Porsche 997.2 Cup Car Center Locks

Wheels – BBS 18″ 3-piece 997.2 Cup Car Wheels (3 sets)

Tires – Hoosier R6 (F 265/35/18, R 315/30/18)

Roll bar, harness bar, shock tower brace – GMG WC version

Porsche Motorsport Cup Car 997.2 rear decklid, Cup Car uprights, ALMS wing

Porsche Motorsport Cup Car 997.2 front fenders

Porsche Motorsport Cup Car front tow hook

Guards LSD

AutoQuest sequential shifter system w auto blipper

Aasco lightweight flywheel, RS 4.0 clutch, pressure plate

GMG World Challenge CF front splitter

Stay tuned….still more to come.

Leave A Comment

You must be logged in to post a comment.